Bold architectural ideas often fail not because they are not buildable, but because the gap between concept and constructability cannot be estimated. For decision makers in the architecture, engineering, and construction (AEC) industry, 3D modeling is the technical bridge that turns provocative geometry into predictable delivery. This article outlines the concrete challenges posed by ambitious designs, the 3D BIM techniques that mitigate them, how those techniques integrate with construction phases, and what to watch for next. All with actionable steps that teams can adopt immediately.

Why 3D Modeling Matters for Daring Design

When a design introduces complex geometry, unconventional assemblies, or tight performance tolerances, the traditional 2D-to-field approach generates uncertainty. That uncertainty becomes rework, schedule drift, and cost overruns. Industry studies show rework typically represents 9% of total project cost and can be substantially higher when indirect costs are considered. These losses are avoidable when Revit BIM Modeling Services are used, and disciplined workflows are applied early and consistently.

Challenges of Modeling Complex Ideas

- Geometry Complexity: Freeform surfaces, nested curved elements, and hybrid steel-concrete connections demand parametric precision. Manual CAD tricks do not scale for fabrication-level detail.

- Coordination Gaps: Separate discipline models that are not interoperable create clashes that surface on site. Reports say up to 70% of total rework experienced in construction and engineering products is a result of design-induced rework, which leads to cost overrun and missed schedule.

- Rework and Project Scale: Large projects are often vulnerable. Megaproject analysis shows that when uncertainties are not modeled and managed, they cause systemic cost and schedule overruns.

Core 3D BIM Techniques to Implement Bold Ideas

Parametric Revit BIM Modeling and Family-Driven Design

Use parametric Revit families to encode performance rules, tolerances, and fabrication constraints into the model. This reduces manual edits when a primary dimension changes.

Practical Step: Require all unusual geometries to be represented as parametric components by the end of schematic design to preserve intent through subsequent phases.

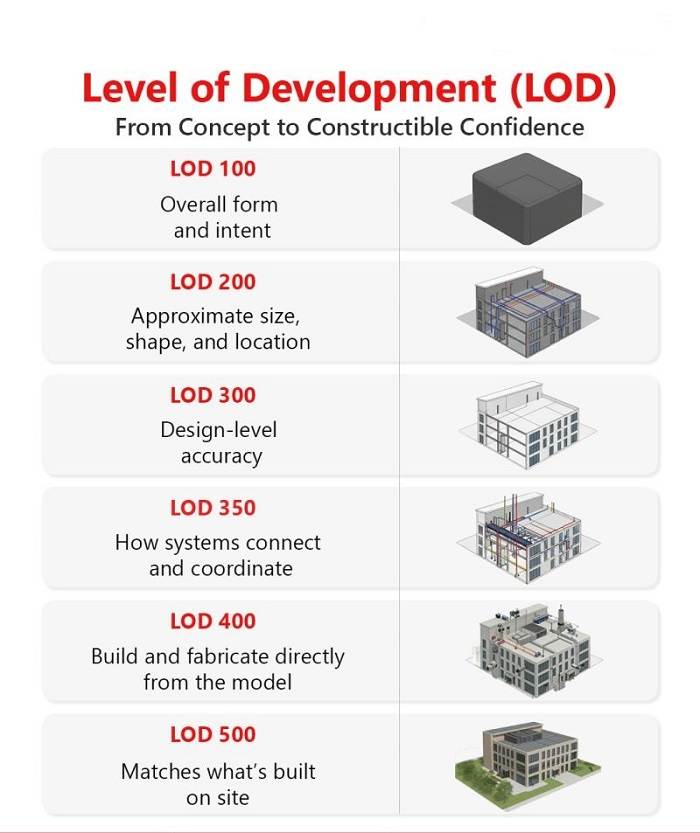

Level of Development (LOD) Progression

Adopt a staged LOD plan that ties modeling maturity to project milestones. For bold façades and structural innovations, move critical components to fabrication LOD earlier than standard practice.

Practical Step: Define LOD acceptance criteria in the BIM Execution Plan and link them to procurement gates.

Tool Integration and Open Exchange

Tool Integration and Open Exchange

Integrate authoring tools, analysis engines, and federated model checkers through IFC or automated exports. Using automated rules reduces manual error-prone translation steps.

Practical Step: Standardize a single federated model format for coordination meetings and mandate automated clash reports before contractor buy-in.

Workflow Implementation Across Design and Construction

Proactive Clash Detection Workflow

Schedule iterative clash detection at concept, design development, and preconstruction. Automate severity classification so teams triage real conflicts quickly.

Pro Tips: Run federated clash tests and issue a prioritized report within 72 hours of each design stage.

Multi-Disciplinary Collaboration Protocols

Include a clear responsibility matrix. Who owns an element, who approves changes, and how changes are published in the Common Data Environment (CDE). This eliminates duplicate corrections and inconsistent versions.

Pro Tips: Institute a weekly coordination workshop with a rotating discipline lead to review high-risk zones and update the assumption log.

Model-Driven Construction Deliverables

Use data-driven 3D Building Information Model to generate shop drawings, fabrication outputs, and offsite assembly instructions. Doing so closes the loop between design intent and field execution, along with it reduces interpretation risk.

For example, early VDC investment on a large design-build food facility helped uncover and resolve 932 high-priority clashes. As a result, it saved more than two million dollars in rework costs, illustrating the ROI of disciplined model coordination.

Future Trends that Affect Bold Design Execution

AI-powered Modeling and Rule-Based Automation

Machine learning tools are now automating routine geometry generation and clash detection, which frees experienced staff to focus on design decisions rather than data cleanup.

Scan to BIM and Digital Twins

Reality capture links existing conditions directly into the design model, enabling precise retrofit and complex insertions where tolerance is critical. The Scan to BIM modeling services market is expanding rapidly as owners demand accurate as-built digital twins.

Market Maturity and Scale

Studies predict the global building information modeling market to expand its size to USD 23.74 billion by 2033, with an annual growth rate of 11.8% from 2025 to 2033. This signifies the industry’s stronger capacity to employ advanced model-driven workflows for complex projects with its continuous growth.

Conclusion: Practical Takeaways for Decision Makers

The effectiveness of BIM 3D modeling is determined mainly by the support it provides for the decisions taken down the line. The application of clear parametric modeling, disciplined LOD progression, and consistent coordination protocols eliminates uncertainty as construction starts after the design has been completed. These practices enable the teams to verify the constructability of the design during the preconstruction stage. BIM modeling services limit the design changes that happen late in the design-build process and maintain alignment among the various disciplines involved.

The architects, engineers, and BIM managers have to shift their attention from just visual improvement to operational clarity. A Revit model that is well-organized becomes a shared technical reference that helps in fabricating, sequencing, and executing in the field. When the decisions made during the modeling are considered project controls instead of documentation tasks, the project teams can be more certain in terms of cost, schedule, and delivery outcomes.

About Author:

I’m Ar. Ankit Kansara, the driving force behind Virtual Building Studio as its Founder & CEO. Our mission is as crystal clear as a blueprint: we’re here to empower AEC professionals with seamlessly integrated, innovative, and cost-effective From BIM Modeling Services USA, MEP BIM services, and Value Engineering, we’ve got the full spectrum of BIM expertise under one roof.

I’m Ar. Ankit Kansara, the driving force behind Virtual Building Studio as its Founder & CEO. Our mission is as crystal clear as a blueprint: we’re here to empower AEC professionals with seamlessly integrated, innovative, and cost-effective From BIM Modeling Services USA, MEP BIM services, and Value Engineering, we’ve got the full spectrum of BIM expertise under one roof.