The Rise of Eco-Friendly Concrete Construction: Adapting to Environmental Regulations and Growing Demand for Sustainable Practices

The construction industry stands at a pivotal crossroads where environmental responsibility and regulatory compliance are reshaping traditional building practices. Eco-friendly concrete construction has emerged as a transformative force, addressing the urgent need to reduce carbon emissions while maintaining the structural integrity and performance standards that modern infrastructure demands.

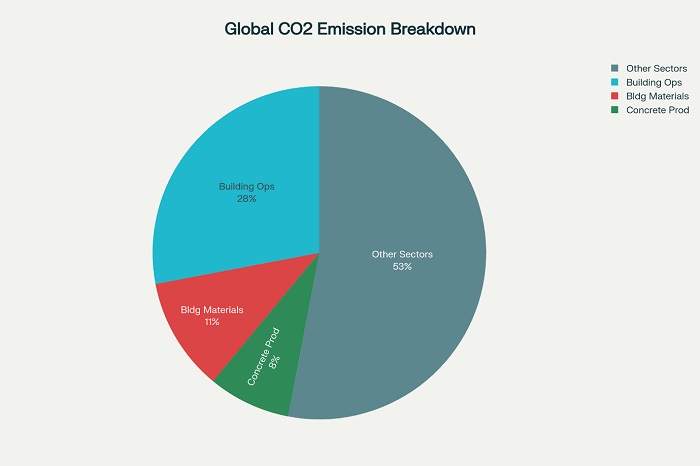

Global Carbon Emissions Breakdown: Construction and Buildings Sector Impact

Global Carbon Emissions Breakdown: Construction and Buildings Sector Impact

The concrete industry faces unprecedented pressure to innovate, as traditional cement production contributes significantly to global carbon emissions. Current data reveals that buildings account for 34% of global energy-related carbon emissions, with 11% stemming directly from materials and construction processes. This sobering reality has catalyzed a revolution in concrete manufacturing, driving the development of sustainable alternatives that promise substantial environmental benefits without compromising quality.

Environmental Regulations Driving Change

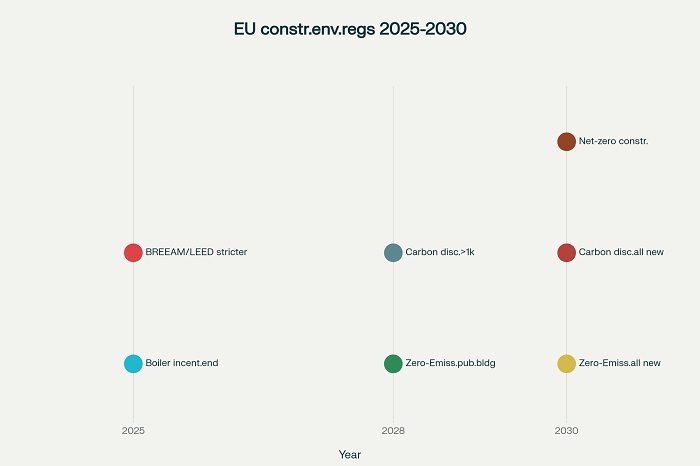

The regulatory landscape governing construction materials has undergone dramatic transformation, with environmental compliance becoming mandatory rather than voluntary. The revised Energy Performance of Buildings Directive (EPBD) represents a watershed moment for the industry, establishing zero-emission buildings as the new standard for construction by 2030.

These regulations extend beyond operational efficiency to encompass whole life-cycle carbon assessments, fundamentally altering how developers approach material selection and construction planning. From 2028, large new buildings exceeding 1000 square meters must disclose their entire carbon footprint, including embodied emissions from materials and construction processes. This requirement expands to all new buildings by 2030, creating an unprecedented level of transparency and accountability in the construction sector.

Timeline of Environmental Regulations Transforming Construction Industry (2025-2050)

Timeline of Environmental Regulations Transforming Construction Industry (2025-2050)

The United Kingdom has implemented equally stringent measures through the RICS Whole Life Carbon Assessment Standard and the UK Net Zero Carbon Buildings Standard, both established in 2024. These frameworks demand comprehensive evaluation of carbon emissions throughout a building’s lifecycle, from material extraction through end-of-life disposal. Compliance with these standards has become essential for developers seeking to navigate the evolving regulatory environment and secure project approvals.

Breakthrough Technologies in Sustainable Concrete

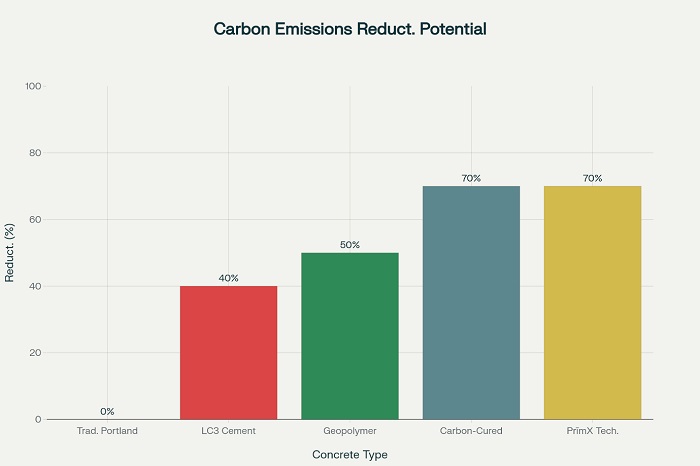

The development of low-carbon concrete alternatives has accelerated dramatically, with multiple technologies demonstrating remarkable potential for emission reduction. Limestone Calcined Clay Cement (LC3) represents one of the most promising innovations, capable of reducing emissions by up to 40% compared to conventional cement. This blended cement replaces significant portions of energy-intensive clinker with calcined clay and limestone, both requiring substantially less energy and producing fewer emissions during production.

Carbon Emission Reduction Potential of Eco-Friendly Concrete Alternatives

Carbon Emission Reduction Potential of Eco-Friendly Concrete Alternatives

Geopolymer concrete offers even greater environmental benefits, utilizing industrial by-products such as fly ash from power plants and slag from steel mills to create concrete with comparable strength characteristics. Studies indicate that geopolymer concrete can achieve emission reductions exceeding 50% while providing superior fire and chemical resistance compared to traditional alternatives. The technology effectively transforms waste materials that would otherwise require landfill disposal into valuable construction resources.

Carbon-cured concrete represents perhaps the most innovative approach to emission reduction, actively incorporating captured carbon dioxide into the concrete matrix during the curing process. Companies like Fortera have pioneered this technology, demonstrating potential emission reductions of 70% while simultaneously improving concrete strength. The process involves injecting captured CO₂ into wet concrete, where it forms solid calcium carbonate that becomes permanently embedded in the material structure.

Market Adoption and Performance Validation

The transition from laboratory innovation to commercial implementation has gained significant momentum, with several major projects demonstrating the viability of sustainable concrete technologies. Holcim’s ECOPact range exemplifies this progression, offering concrete with 50% lower carbon emissions compared to standard formulations while maintaining equivalent performance characteristics. The company’s approach involves transparent reporting of carbon factors and comprehensive Environmental Product Declarations (EPDs) to support informed decision-making by developers and contractors.

Early adopters report that buildings constructed with LC3 and geopolymer concrete perform comparably to those using traditional materials, validating the structural integrity and durability of these alternatives. The concrete sector’s commitment to achieving net-zero emissions by 2050 through the Global Cement and Concrete Association has intensified research and development efforts, spurring rapid technological advancement across the industry.

PrīmX technology demonstrates another successful commercial application, featuring optimized mix designs and reduced slab cross-sections that consume less cement and steel while achieving emission reductions of up to 70%. The jointless nature of PrīmX concrete eliminates the need for joint sawing, reducing both construction time and hazardous silica dust emissions.

Economic Implications and Industry Response

The economic dynamics of sustainable concrete adoption reveal a complex interplay between initial investment costs and long-term value creation. While eco-friendly materials often command higher upfront prices, the total cost of ownership frequently favors sustainable alternatives when considering lifecycle benefits. Energy-efficient buildings constructed with low-carbon concrete typically demonstrate reduced operational costs, with some projects reporting 21-23% decreases in the first year and 43-49% reductions within five years.

The increasing prevalence of green building certifications has created market incentives for sustainable material adoption. Over 20% of new commercial buildings in OECD countries achieved green certification in 2023, representing a significant increase from 15% in 2020. BREEAM and LEED standards are being updated to stricter levels by mid-2025, with enhanced performance thresholds for energy use, carbon reduction, and sustainable materials.

Government procurement policies increasingly favor low-carbon construction materials, creating substantial market demand for sustainable alternatives. The UK Emissions Trading Scheme adds financial pressure on carbon-intensive production processes, making low-emission alternatives more economically attractive. These policy mechanisms effectively internalize environmental costs, shifting market dynamics in favor of sustainable technologies.

Technical Innovation and Quality Assurance

The development of self-healing concrete represents a significant advancement in sustainable construction technology, offering enhanced durability while reducing maintenance requirements. This innovative material incorporates bacteria that produce limestone to seal cracks automatically, extending structural lifespan and reducing the need for repairs and replacements. Sensicon reports that self-healing concrete can achieve 30-40% reductions in maintenance requirements due to improved water resistance, directly contributing to cost savings and emission reductions.

Quality assurance protocols for sustainable concrete have evolved to match the sophistication of the materials themselves. Environmental Product Declarations (EPDs) provide standardized assessments of lifecycle impacts, covering carbon emissions, water usage, and resource depletion. These transparent reporting mechanisms enable informed decision-making while building confidence in sustainable alternatives among developers and regulatory authorities.

Carbon capture, utilization, and storage (CCUS) technologies are being integrated into cement production facilities to further reduce emission intensity. These systems capture CO₂ emissions during production and either permanently store them or utilize them in concrete manufacturing processes, creating closed-loop systems that minimize environmental impact.

Future Outlook and Industry Transformation

The trajectory toward widespread adoption of eco-friendly concrete construction appears irreversible, driven by regulatory requirements, market demand, and technological advancement. Industry experts predict that cement-based blocks may face market rejection within two decades unless significant sustainability improvements are achieved. This timeline reflects the accelerating pace of environmental consciousness and regulatory enforcement across the construction sector.

Regional customization of sustainable concrete solutions is emerging as manufacturers adapt formulations to local climate conditions and material availability. This localization strategy reduces transportation emissions while optimizing performance characteristics for specific environmental conditions. India’s introduction of national standards for LC3 cement exemplifies this trend, with the country positioning itself as a leader in sustainable cement adoption.

The convergence of digital technologies with sustainable construction is creating new opportunities for optimization and efficiency. Digital twins and artificial intelligence are being deployed to predict building performance and optimize material usage, while blockchain technology enhances supply chain transparency and material traceability. These technological integrations promise to accelerate the transition to sustainable construction practices while improving overall project outcomes.

The rise of eco-friendly concrete construction represents more than a technological evolution; it embodies a fundamental shift toward environmental stewardship and sustainable development. As regulatory frameworks tighten and market demand intensifies, the construction industry must embrace these innovations to remain competitive and compliant. The evidence suggests that sustainable concrete technologies not only meet environmental objectives but often exceed the performance characteristics of traditional alternatives, positioning eco-friendly construction as the inevitable future of the industry.