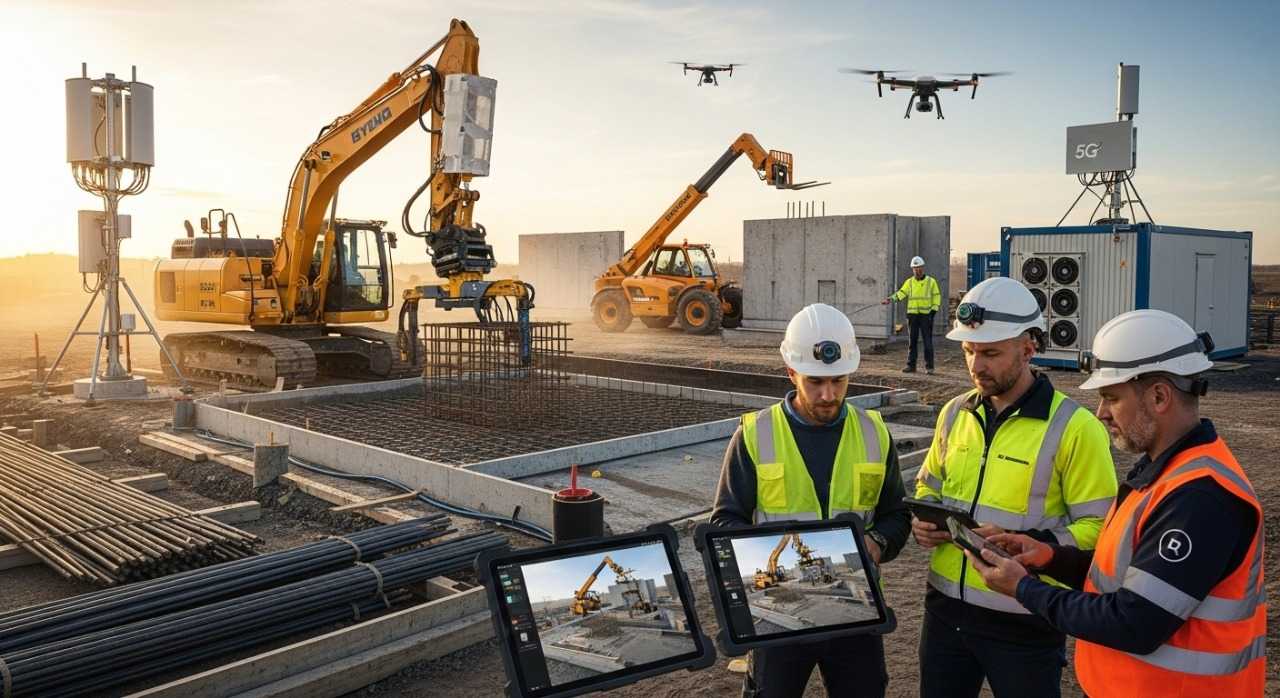

Cross-Industry Innovation Partnerships Accelerating Technology Adoption in Construction

The construction industry has historically operated as an insular ecosystem, relying primarily on internal innovation and traditional suppliers for technological advancement. However, the emergence of cross-industry innovation partnerships is fundamentally transforming this paradigm, creating unprecedented opportunities for rapid technology adoption and operational transformation. These strategic collaborations between construction companies and technology providers from diverse sectors including aerospace, automotive, telecommunications, and manufacturing are accelerating innovation cycles while introducing revolutionary capabilities that would be impossible to develop independently.

Understanding the Paradigm Shift Toward Collaborative Innovation

The traditional construction technology development model relied on incremental improvements from established industry suppliers, resulting in slow innovation cycles and limited breakthrough capabilities. Cross-industry innovation partnerships represent a fundamental departure from this approach, enabling construction companies to leverage cutting-edge technologies, methodologies, and expertise from sectors with more mature digital transformation experiences.

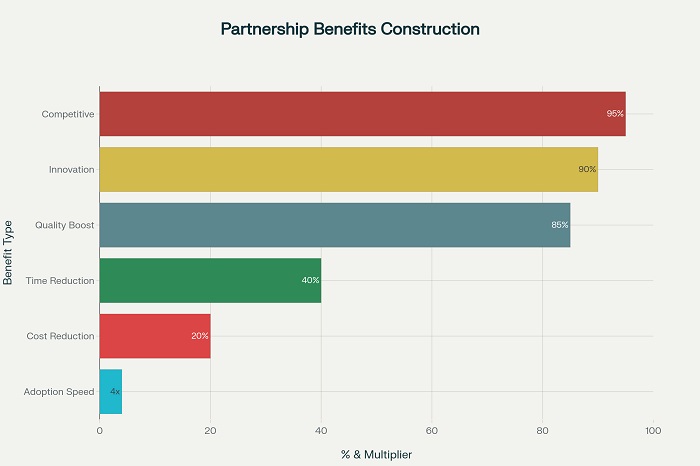

The global construction industry recognizes the transformative potential of collaborative innovation, with companies increasingly seeking partnerships that transcend traditional industry boundaries. Research indicates that construction companies implementing cross-industry partnerships achieve technology adoption rates 3-5 times faster than those relying solely on internal development or traditional supplier relationships. This acceleration stems from accessing proven technologies, established development methodologies, and specialized expertise that would require years to develop internally.

Modern cross-industry partnerships encompass diverse collaboration models including technology licensing agreements, joint development initiatives, strategic alliances, and innovation consortiums that combine resources and expertise from multiple sectors. These partnerships enable construction companies to access advanced technologies including artificial intelligence platforms, autonomous systems, advanced materials, sensor technologies, and communication networks that have been refined through applications in other demanding industries.

The success of these partnerships depends on identifying complementary capabilities, shared objectives, and mutual value creation opportunities that benefit all participants. Effective cross-industry collaboration requires understanding how technologies and methodologies from other sectors can be adapted and optimized for construction applications while leveraging construction industry expertise to enhance partner capabilities.

Aerospace and Defense Technology Integration

The aerospace and defense industries offer sophisticated technologies that translate exceptionally well to construction applications, particularly in areas requiring precision, reliability, and advanced automation capabilities. Cross-industry innovation partnerships with aerospace companies have introduced construction to advanced materials, precision manufacturing techniques, autonomous systems, and sophisticated quality control methodologies.

Advanced composite materials developed for aerospace applications provide construction with lightweight, high-strength alternatives to traditional materials. These composites offer superior strength-to-weight ratios, corrosion resistance, and design flexibility that enable innovative architectural solutions while reducing structural loads and improving energy efficiency. Partnership initiatives have successfully adapted aerospace-grade composites for building facades, structural elements, and prefabricated components.

Precision manufacturing and quality control systems from aerospace applications enhance construction productivity and quality outcomes. Aerospace manufacturing employs rigorous quality standards, advanced inspection techniques, and sophisticated process controls that significantly exceed traditional construction practices. Partnerships with aerospace companies have introduced construction to laser measurement systems, automated inspection technologies, and statistical process control methodologies that dramatically improve construction quality and reduce defect rates.

Autonomous navigation and control systems developed for aerospace applications provide construction with advanced capabilities for equipment operation, site monitoring, and logistics management. Aerospace expertise in autonomous systems, sensor fusion, and navigation technologies enables construction equipment to operate with unprecedented precision and safety. These partnerships have accelerated the development of autonomous construction equipment that surpasses capabilities achievable through traditional construction technology development.

Drone technology represents one of the most successful examples of aerospace-construction collaboration, with unmanned aerial systems originally developed for military applications now providing essential capabilities for site surveying, progress monitoring, and inspection activities. The construction industry’s adoption of drone technology exemplifies how cross-industry partnerships can rapidly introduce transformative capabilities while accelerating technological maturation through diverse application experiences.

Automotive Industry Manufacturing and Automation Expertise

The automotive industry’s decades of experience with mass production, automation, and lean manufacturing methodologies offer valuable insights and technologies for construction operations. Cross-industry innovation partnerships with automotive companies introduce construction to advanced manufacturing techniques, quality systems, and automation technologies that significantly improve productivity and consistency.

Lean manufacturing principles developed and refined through automotive applications provide construction with systematic approaches to waste reduction, process optimization, and quality improvement. These methodologies enable construction companies to identify inefficiencies, eliminate non-value-added activities, and optimize workflows for maximum productivity. Automotive partnerships have successfully introduced construction to value stream mapping, continuous improvement processes, and standardized work methodologies.

Advanced robotics and automation systems from automotive manufacturing provide construction with sophisticated capabilities for repetitive tasks, precision assembly, and quality control. Automotive assembly line robots can be adapted for construction applications including masonry installation, welding operations, and material handling tasks that require consistent quality and high productivity rates. These partnerships accelerate construction automation adoption while leveraging decades of automotive robotics development experience.

Quality management systems from automotive applications offer construction robust methodologies for ensuring consistent quality outcomes and continuous improvement. Automotive quality systems including Six Sigma methodologies, statistical process control, and supplier quality management provide construction with proven approaches to quality management that significantly exceed traditional construction practices. Partnership implementations have demonstrated substantial improvements in construction quality metrics and customer satisfaction.

Supply chain management expertise from automotive applications enables construction companies to optimize material flows, reduce inventory costs, and improve delivery reliability. Automotive supply chains represent some of the most sophisticated logistics operations globally, with capabilities including just-in-time delivery, supplier quality management, and advanced demand forecasting. Construction partnerships with automotive companies have introduced these capabilities to construction operations with measurable improvements in cost and schedule performance.

Telecommunications and Digital Infrastructure Collaboration

The telecommunications industry’s expertise in network infrastructure, data management, and connectivity solutions provides essential foundations for construction digitalization initiatives. Cross-industry innovation partnerships with telecommunications companies enable construction sites to achieve robust connectivity, comprehensive data integration, and advanced communication capabilities necessary for modern construction operations.

5G network deployment and edge computing capabilities from telecommunications companies provide construction sites with high-speed, low-latency connectivity that supports advanced applications including real-time monitoring, remote operation, and autonomous equipment coordination. These partnerships enable construction companies to access cutting-edge communication infrastructure while telecommunications companies gain opportunities to develop and demonstrate new applications for their technologies.

Advanced data analytics and machine learning platforms developed for telecommunications applications provide construction with sophisticated capabilities for processing and analyzing operational data. Telecommunications companies have extensive experience with big data processing, predictive analytics, and artificial intelligence applications that translate well to construction applications including equipment monitoring, performance optimization, and predictive maintenance.

Cybersecurity expertise from telecommunications companies addresses critical security requirements for increasingly connected construction operations. As construction sites become more digitized and interconnected, cybersecurity becomes essential for protecting sensitive project information, operational data, and control systems. Telecommunications partnerships provide construction with proven security frameworks, threat detection capabilities, and incident response procedures.

Internet of Things (IoT) platforms and device management capabilities from telecommunications companies enable construction sites to deploy comprehensive sensor networks and monitoring systems. Telecommunications companies have extensive experience with IoT device management, data collection, and network optimization that supports construction applications including environmental monitoring, equipment tracking, and worker safety systems.

Manufacturing Industry Process Optimization and Quality Systems

Manufacturing industry partnerships provide construction with advanced process optimization methodologies, quality management systems, and continuous improvement practices that significantly enhance operational performance. Cross-industry innovation partnerships with manufacturing companies introduce construction to sophisticated approaches for managing complex operations while maintaining quality standards and cost efficiency.

Advanced planning and scheduling systems from manufacturing applications provide construction with capabilities for optimizing resource allocation, coordinating complex workflows, and minimizing project delays. Manufacturing companies have developed sophisticated planning methodologies including advanced production scheduling, capacity optimization, and resource balancing that translate effectively to construction project management. These partnerships have demonstrated significant improvements in construction schedule adherence and resource utilization.

Total Quality Management (TQM) principles and implementation methodologies from manufacturing provide construction with comprehensive approaches to quality improvement and customer satisfaction. Manufacturing quality systems including ISO standards, quality auditing procedures, and supplier quality management offer construction proven methodologies for achieving consistent quality outcomes while reducing defects and rework.

Predictive maintenance technologies and methodologies developed for manufacturing applications provide construction equipment with advanced monitoring and maintenance optimization capabilities. Manufacturing companies have extensive experience with vibration analysis, thermal monitoring, and predictive analytics that enable early problem detection and optimized maintenance scheduling. These partnerships introduce construction to proven maintenance technologies while accelerating implementation through shared expertise.

Industry 4.0 technologies including digital twins, advanced automation, and integrated data systems from manufacturing applications provide construction with sophisticated capabilities for managing complex projects and optimizing operations. Manufacturing companies have pioneered many Industry 4.0 technologies that are now being adapted for construction applications through collaborative partnerships.

Technology Sector Software and Platform Development

Technology sector partnerships provide construction with access to advanced software platforms, development methodologies, and digital capabilities that accelerate construction digitalization initiatives. Cross-industry innovation partnerships with technology companies enable construction to leverage cutting-edge software development practices, cloud computing platforms, and artificial intelligence capabilities.

Cloud computing platforms and services from technology companies provide construction with scalable, secure, and cost-effective infrastructure for digital applications. Technology partnerships enable construction companies to access enterprise-grade computing resources, data storage capabilities, and software development tools without requiring substantial internal IT investments. These partnerships accelerate construction digitalization while providing technology companies with opportunities to develop industry-specific solutions.

Artificial intelligence and machine learning platforms from technology companies provide construction with advanced analytical capabilities for processing complex data sets and supporting decision-making processes. Technology sector expertise in AI development, algorithm optimization, and platform scaling enables construction applications that would be prohibitively expensive to develop independently. These partnerships have accelerated construction AI adoption across applications including project planning, quality control, and predictive maintenance.

Software development methodologies including agile development practices, DevOps procedures, and continuous integration approaches from technology companies improve construction software development capabilities. Technology partnerships introduce construction to proven development practices that accelerate software deployment while improving reliability and maintainability.

Cybersecurity platforms and services from technology companies address critical security requirements for construction digital infrastructure. Technology sector cybersecurity expertise provides construction with advanced threat detection, incident response, and security management capabilities essential for protecting increasingly connected construction operations.

Healthcare and Life Sciences Safety and Monitoring Technologies

Healthcare industry partnerships introduce construction to advanced safety monitoring technologies, ergonomic assessment methodologies, and worker health management systems that significantly enhance workplace safety outcomes. Cross-industry innovation partnerships with healthcare companies leverage medical technology expertise to address construction’s persistent safety challenges.

Wearable health monitoring technologies developed for medical applications provide construction with advanced capabilities for tracking worker vital signs, detecting fatigue, and preventing health-related incidents. Healthcare expertise in biosensor development, data analysis, and health monitoring enables construction safety applications that surpass traditional safety approaches while providing continuous protection for construction workers.

Ergonomic assessment and intervention technologies from healthcare applications help construction companies identify and address workplace factors that contribute to musculoskeletal injuries. Healthcare partnerships introduce construction to advanced ergonomic evaluation techniques, intervention strategies, and injury prevention programs that significantly reduce workplace injury rates.

Telemedicine and remote monitoring capabilities from healthcare applications provide construction sites with access to medical expertise and emergency response capabilities in remote locations. Healthcare partnerships enable construction projects to maintain comprehensive health and safety support regardless of location while reducing response times for medical emergencies.

Rehabilitation and return-to-work technologies from healthcare applications help construction companies support injured workers while minimizing productivity losses. Healthcare expertise in injury recovery, physical therapy, and return-to-work programs provides construction with proven methodologies for managing workplace injuries while maintaining worker health and productivity.

Overcoming Partnership Implementation Challenges

Successfully implementing cross-industry innovation partnerships requires addressing cultural differences, technical integration challenges, and organizational alignment issues that can impede collaboration effectiveness. Construction companies must develop strategic approaches to partnership management while building internal capabilities for cross-industry collaboration.

Cultural integration represents a significant challenge as different industries often have distinct approaches to risk management, quality standards, and operational procedures. Successful partnerships require establishing shared objectives, communication protocols, and decision-making processes that accommodate different organizational cultures while maintaining focus on mutual value creation.

Technical integration challenges arise when combining technologies and systems from different industries with varying standards, protocols, and operational requirements. Effective partnerships require comprehensive technical planning, system integration expertise, and often custom development work to achieve seamless operation across different technology platforms.

Intellectual property management becomes complex in cross-industry partnerships where different companies contribute proprietary technologies and expertise. Successful partnerships require clear intellectual property agreements, licensing arrangements, and technology sharing protocols that protect participant interests while enabling effective collaboration.

Change management requirements accompany cross-industry partnerships as organizations must adapt to new technologies, methodologies, and collaborative approaches. Successful implementation requires comprehensive training programs, organizational change initiatives, and leadership commitment to support partnership success.

Measuring Partnership Success and Value Creation

Effective measurement of partnership outcomes requires comprehensive metrics that capture both quantitative benefits and qualitative improvements in capabilities and competitive positioning. Cross-industry innovation partnerships should demonstrate measurable value through improved operational performance, accelerated innovation cycles, and enhanced competitive advantages.

Financial performance metrics including cost reductions, revenue increases, and return on investment provide essential indicators of partnership value creation. Successful partnerships typically demonstrate measurable improvements in operational efficiency, reduced development costs, and accelerated time-to-market for new capabilities. Companies report average cost reductions of 15-25% and development time reductions of 30-50% through effective cross-industry partnerships.

Innovation capability metrics assess improvements in technology adoption rates, development cycle times, and innovation pipeline strength. Partnerships should enhance organizational capabilities for identifying, evaluating, and implementing new technologies while building internal expertise for ongoing innovation activities.

Competitive advantage metrics evaluate improvements in market positioning, customer satisfaction, and differentiation capabilities achieved through partnership activities. Successful partnerships should enhance competitive positioning while creating sustainable advantages that justify ongoing collaboration investments.

Operational performance metrics including productivity improvements, quality enhancements, and safety outcomes provide direct evidence of partnership effectiveness. These metrics should demonstrate tangible improvements in core business operations while validating the practical value of cross-industry collaboration.

Future Evolution and Emerging Partnership Opportunities

The trajectory of cross-industry innovation partnerships points toward even more sophisticated collaboration models as digital transformation accelerates and industry boundaries continue to blur. Emerging technologies including quantum computing, advanced materials, and biotechnology create new opportunities for cross-industry innovation partnerships that could fundamentally transform construction operations.

Quantum computing partnerships may eventually provide construction with unprecedented computational capabilities for optimization problems, simulation applications, and artificial intelligence tasks that exceed current technological limitations. Early exploration of quantum computing applications in construction planning and optimization suggests significant potential for revolutionary improvements in complex problem-solving capabilities.

Biotechnology partnerships offer potential opportunities for developing self-healing materials, bio-based construction components, and environmental monitoring capabilities that could transform construction sustainability and performance characteristics. Biotechnology expertise in materials science, environmental science, and biological systems could introduce construction to entirely new categories of building materials and environmental management techniques.

Advanced materials partnerships continue expanding as nanotechnology, smart materials, and composite technologies create new possibilities for construction applications. These partnerships enable construction access to materials with unprecedented properties including self-monitoring capabilities, adaptive characteristics, and enhanced performance attributes.

Space technology partnerships represent an emerging frontier as space industry capabilities in extreme environment operations, life support systems, and advanced manufacturing techniques become relevant for construction applications in challenging environments and sustainable building development.

Conclusion

Cross-industry innovation partnerships represent a fundamental transformation in how the construction industry approaches technology development and adoption, creating unprecedented opportunities for rapid innovation while leveraging expertise and capabilities from diverse sectors. These collaborative relationships enable construction companies to access cutting-edge technologies, proven methodologies, and specialized expertise that would be impossible to develop independently while contributing construction industry knowledge to enhance partner capabilities.

The construction industry’s embrace of cross-industry partnerships accelerates as organizations recognize the competitive advantages and operational improvements achievable through strategic collaboration. Early adopters demonstrate that effective partnerships not only accelerate technology adoption but also enhance innovation capabilities, improve competitive positioning, and create sustainable value for all participants.

The future of construction innovation lies in the intelligent integration of capabilities and expertise from multiple industries that combine to create solutions surpassing what any single industry could achieve independently. Organizations that successfully develop and manage cross-industry innovation partnerships will lead the construction industry’s transformation toward more sophisticated, efficient, and technologically advanced operations that redefine the standards for construction project delivery and operational excellence.