Some things on earth improved and became better because of sensory technology. At the heart of these discoveries and efforts to help people live better, many invent devices that make life easier in general. Sensory technology is one of them, and this is not a single product with its own distinctions. Instead, it’s best to know that this is an integral part of the products that many people use today.

Overall, sensory technology ensures that the resulting products perform at their optimal levels. It’s a part of many gadgets, and there’s a reason why so many consumers are not aware that they exist. However, with the significant contributions and roles that they play in society, it’s best to understand and appreciate this kind of technology and know all about it.

This is why this post will shed some information about the basics of many ultrasonic products that are usually based on electrostatic technology. There are parts, electronics accessories, and kits from SensComp that will provide you with more in-depth information about their looks and descriptions, so you may want to check them out first. Also, by knowing about these kinds of newer technologies, you can always put them to good use when the time comes that you’re going to need them.

Concept Behind the Ultrasonic Technology

The concept or the notion behind these sensors is to have a device that will enable the calculation of distances through time. This is the ability that can benefit people in many ways depending on what their goals are and what they are trying to do.

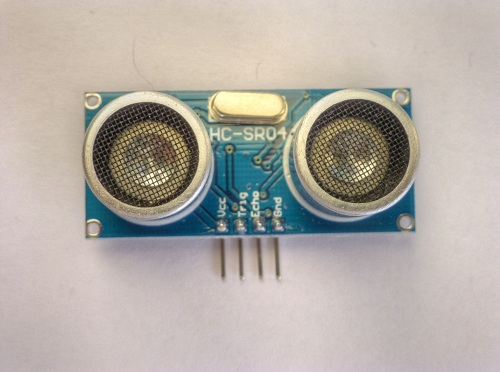

This entire system will work differently depending on the kind of technology that you have. In cases of ultrasonic products, you’re generally getting two electronic devices that will require any contact, but they will still function. This is a sensory technology that requires no contact for the most part, but they should be near each other as much as possible.

Overall, many people find this feature to be impressive, which is why many prefer this to calculate the distance of objects and their velocity. The word “ultrasonic” implies that the sounds are used in this technology, and it’s not a mere coincidence. Some people may even find it peculiar how these products work.

The extensive use of sound calculates the distance and velocity of objects. There’s the ability to transmit, convert, and emit sound waves through the devices at the right time so they can be applied through various applications. The results are known to be electric signals as long as everything was timed right, and the products worked well.

Although the overall work uses sound waves, you may not detect these when using specialized devices. The reason for this is that these waves are beyond the detectable range of humans, but they can remain powerful when used appropriately.

There are various parts of the products and sensors, as well as the roles that they play. Regardless of the functions, the two components would consist of a transmitter and receiver. The rated voltage, beam angle, and frequency should be done right for them to work appropriately.

More about the Ultrasonic Sensors

With these non-contact devices used to measure the velocity and distance of the objects, they can be applied in various industries. They essentially convert the sound waves into electric signals that are more audible than the human range.

The Doppel Shift property of the sound waves is used to measure an object’s velocity. The flight time is used to measure the distance. Transmitters emit sound with the help of electrostatic technology and piezoelectric crystals. The receiver will come in contact with the sound waves after it has traveled back from an object.

They might be utilized as proximity sensors where they are common in anti-collision safety technology systems and self-parking applications. Some are even used in robotics, manufacturing, and obstacle detection. When comparing them to the infrared system, they are not usually susceptible to gas or smoke interference. However, the sound sensors may be affected by heat.

Ultrasonic sensors may be used as level sensors or for ranging measurements. They monitor, regulate, and detect liquids in many containers. They are helpful in the medical industry for the identification of tumors. Most of them are used to view images of babies in the womb or see if there are problems with one’s internal organs.

About the Transducers

Ultrasonic transducers are based on the principles of piezoelectric or electrostatic. You can read more information about piezoelectricity at this link here. These transducers may provide excellent outputs in various pressure levels, but they might have narrow bandwidth.

The signals can consist of very short durations generated from the device or received. They are used because of their wide bandwidth, and the aperture transducers are easy to implement. How they work is similar to that of the capacitive microphones, which are very accurate and suitable for measuring accurate distances.

Generally, the ultrasonic transducers are made up of flexible conductive membranes. They rest on grooved backplates that are highly conductive. When the electric signals are applied to the membranes and the backplates, the former will tend to move away from the latter. Also, when the signals are made in contact with the transducer, the membranes will generally vibrate and generate sound waves in the air.

The electrostatic devices may result in a flat response for a wide frequency range. They may ring out of character or become non-resonant. The result is a more sensitive device compared to the piezo varieties with a difference of 40 dB or more.

Increased sensitivity will mean that the capability is going to be long-range. If you want to apply this in a short-range area, you may want to get accessories with a lower-gain receiver unit. The transducer may cover a site from an inch up to 40 ft when you combine them with proper accessories and electronic drivers. They are excellent choices when you want to measure a very deep tank.