Over the years, the industrial sector has witnessed remarkable advances in measurement technology. The Coordinate Measuring Machine (CMM), a crucial player, has evolved dramatically, ensuring higher precision and accuracy in various industries.

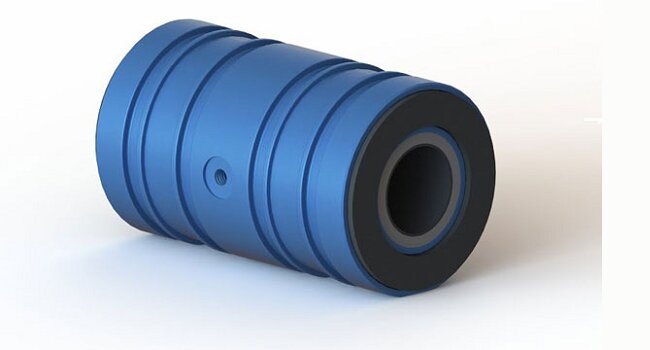

What is an air bearing?

Diving deeper into the intricate mechanics of a CMM, one component stands out: the air bearing. Much like its name suggests, an air bearing utilizes a thin layer of air to separate surfaces, ensuring a near-zero friction environment. Central to its function are core components like orifices, air supply, and bearing surfaces. Through their concerted effort, these components create a fluid film which facilitates the operational principles of load support and constrained motion.

How do air bearings work in the context of CMM?

In the realm of CMM, air bearings have a pivotal role to play. They:

Provide an almost frictionless movement which is pivotal for the precision of measurements.

Ensure consistent stability throughout the CMM’s operational phase.

Significantly reduce wear and tear due to their non-contact nature.

Augment the lifespan of the machine.

What are the primary components of an air bearing in CMM?

Orifice: The outlet from where pressurized air is released.

Bearing Surface: A specially designed surface where the air film is maintained.

Air Supply: Ensures a constant source of air for the bearing.

Restrictors: Control the flow of air to the bearing surface.

How is the air cushion created and maintained?

The air cushion, fundamental to an air bearing, is a result of releasing pressurized air through orifices. This creates a consistent air film between the bearing surfaces. Continuous air supply ensures that the cushion is maintained, which is crucial for the CMM’s precision.

Why are air bearings crucial for CMM?

Air bearings stand as the linchpin in a CMM’s architecture. Their ability to offer almost zero friction means measurements are not only precise but also consistent over repeated operations.

What makes air bearings preferable over traditional bearings in CMM?

The merits of air bearings, especially in a CMM context, are myriad:

Reduced Friction: Virtually eliminates any friction during operations.

No Wear and Tear: As they don’t come in contact, the lifespan is prolonged.

Enhanced Precision: Consistent air film ensures accuracy.

How do air bearings contribute to the accuracy of CMM measurements?

The essence of CMM is its precision. Air bearings play a critical role here. By maintaining a consistent air film, they eradicate any room for error stemming from friction. This ensures that measurements remain accurate, irrespective of the machine’s duration of operation.

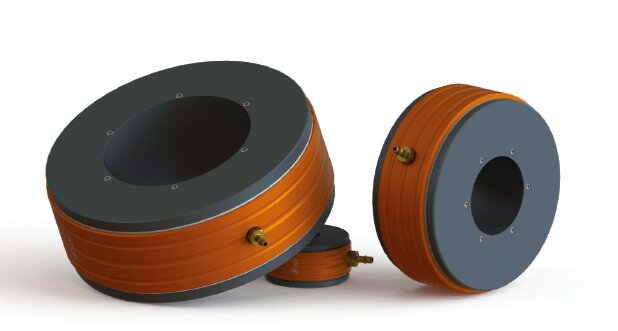

Is the type of air bearing used crucial for specific measurements?

Certainly, different measurements might demand specialized air bearings. Depending on the required precision, load capacity, and operational constraints, selecting an apt air bearing type is crucial for ensuring accurate results.

What are the challenges in using air bearings in CMM?

While they offer numerous benefits, air bearings aren’t devoid of challenges. They require a consistent air supply, making them dependent on external factors. Additionally, environmental contaminants can affect their performance.

How to ensure optimal performance of air bearings?

Ensuring the performance of air bearings in CMM involves:

Regular cleaning to avoid contaminants.

Ensuring a consistent air supply.

Periodic inspections for wear, even if it’s minimal.

Are there any limitations to where or how air bearings can be used in CMMs?

Air bearings thrive in controlled environments. Extreme temperatures, dust, or the presence of other contaminants can affect their performance. In such scenarios, alternative bearing types might be considered.

How do air bearings impact the overall efficiency and life span of CMM?

Integrating air bearings augments the life span of CMM. Their non-contact nature means reduced wear, ensuring the machine’s longevity. Moreover, by eliminating friction, they enhance the machine’s efficiency, ensuring consistent results over time.

What are the maintenance requirements for air bearings in CMM?

Maintenance is straightforward:

Periodic cleaning to eliminate contaminants.

Inspection for uniform air flow.

Ensuring a consistent air supply.

How does the cost of implementing air bearings compare to its benefits in CMM?

While the initial investment might be hefty, the long-term benefits—accuracy, efficiency, and longevity—make air bearings a cost-effective choice for CMM.

What are the future prospects for air bearings in CMM?

With technological advancements, we can anticipate even more refined air bearings, catering specifically to evolving CMM needs.

Are there viable alternatives to air bearings in CMM construction?

While air bearings are predominant, there are alternatives:

Magnetic Bearings: Offer non-contact operations but at a higher cost.

Roller Bearings: Traditional but might compromise on precision.

Fluid Bearings: Use liquid to reduce friction, but the consistency might vary.

Air Bearings and Their Advancements Over Time

The trajectory of air bearings in the CMM landscape isn’t linear. From their initial inception to the sophisticated versions we witness today, they have undergone significant evolution.

The Genesis of Air Bearings in CMM

Air bearings didn’t instantaneously find their way into CMMs. Their adoption was a result of the relentless pursuit of achieving greater accuracy in measurements. The industry’s need for a frictionless and wear-free solution paved the way for air bearings.

Technological Improvements in Air Bearing Design

The chronicles of air bearings in CMMs are replete with technological strides:

Material Advancements: From rudimentary materials to advanced non-corrosive ones, ensuring longevity and durability.

Orifice Design Refinements: Precision in orifice design has enabled the creation of a consistent air cushion.

Air Supply Mechanisms: Evolved to ensure a more stable and efficient air flow.

Real-world Applications and Case Studies

To grasp the tangible impacts of air bearings in CMMs, examining real-world applications becomes essential.

Air Bearings in Aerospace CMM Applications

The aerospace sector, known for its stringent precision standards, heavily relies on CMMs equipped with air bearings. The near-zero friction environment ensures that even the minutest components are measured with impeccable accuracy, a non-negotiable in aerospace dynamics.

Revolutionizing the Automotive Industry

Modern cars, with their intricate components, benefit from the precision of CMMs with air bearings. From ensuring the correct alignment of engine parts to validating the aerodynamics of exteriors, air bearings play a critical role.

Addressing Common Misconceptions

Every innovative technology comes with its fair share of myths. Let’s debunk some pertaining to air bearings.

“Air Bearings are Prone to Failures due to Air Supply Issues”

While air supply consistency is essential, modern air bearings come equipped with backup mechanisms and redundancies to mitigate such concerns.

“They are Exorbitantly Expensive in the Long Run”

Initial investments might be high, but when we factor in reduced maintenance costs and prolonged machine life, they are economically viable.

User Testimonials and Feedback

Feedback from industries and technicians reveals insights into the practical advantages of air bearings in CMMs.

A Testimonial from a Leading Manufacturer

“We transitioned to CMMs with air bearings three years ago. The precision we achieve now was unfathomable before. It’s revolutionized our quality control.”

Feedback from a CMM Technician

“Working with air bearings has reduced the frequency of recalibrations and maintenance downtimes. It’s a game-changer.”

Navigating the Learning Curve

For those new to the domain, understanding and mastering air bearings in CMMs might seem daunting. However, with ample resources, training modules, and expert guidance available, the learning curve is smoother than perceived.

Looking Ahead: The Future of Air Bearings in CMMs

The horizon looks promising for air bearings in the CMM landscape. With ongoing research and innovations, we can anticipate air bearings that cater to even more niche requirements, ensuring that the future of measurements remains as precise as ever.

Conclusion

Circling back to the crux, the significance of air bearings in CMM construction remains unparalleled. They’ve redefined accuracy, enhanced efficiency, and promise a future where measurements are devoid of errors. As industries evolve and demand even more precision, the reliance on air bearings in CMMs will only intensify, marking their indelible imprint in the annals of industrial history.