Waterproofing & Sealants: Protecting the Envelope from Below Grade to Roof

The integrity of any structure fundamentally depends on its ability to control water ingress, making waterproofing concrete structures one of the most critical aspects of modern construction. As building envelopes become more complex and performance expectations increase, innovative waterproofing technologies and advanced sealant systems are revolutionizing how professionals protect structures from water damage. These developments extend far beyond traditional surface treatments, encompassing comprehensive systems that provide long-term protection against the most challenging environmental conditions.

The Critical Importance of Comprehensive Water Protection

Water infiltration represents one of the most persistent and costly challenges in construction, with damage extending far beyond immediate visible effects. Moisture penetration can compromise structural integrity, promote mold growth, damage building systems, and create health hazards for occupants. The economic impact of water damage often exceeds initial construction costs, making effective waterproofing concrete structures essential for long-term building performance and value preservation.

Modern construction projects face increasingly demanding water resistance requirements driven by climate change, extreme weather events, and enhanced building performance standards. These challenges necessitate waterproofing approaches that go beyond traditional surface applications to provide integrated protection systems that address water intrusion pathways throughout the building envelope.

Revolutionary Crystalline Waterproofing Technologies

Penetrative Crystalline Systems

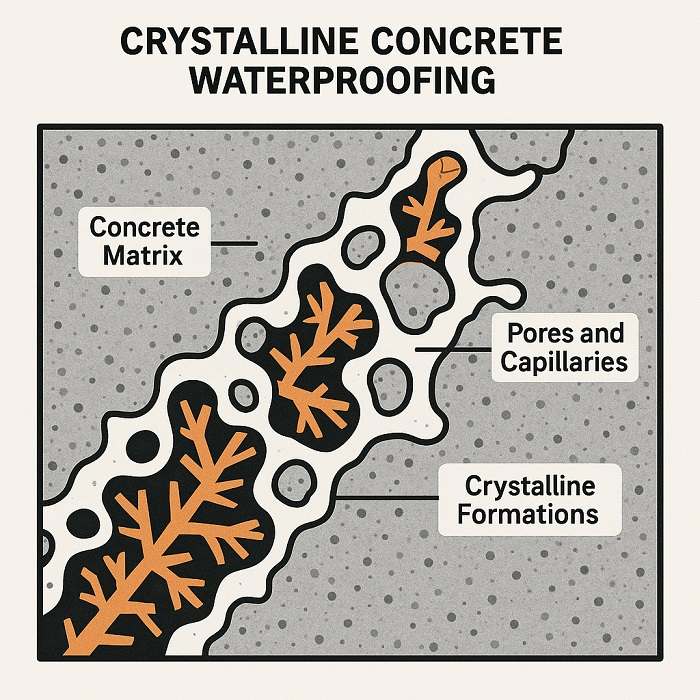

The most significant advancement in waterproofing concrete structures involves crystalline technologies that work within the concrete matrix rather than relying on surface barriers. These systems utilize proprietary chemicals that react with cement hydration byproducts to form non-soluble crystalline structures within concrete pores and capillary networks.

Xypex crystalline technology exemplifies this approach, creating permanent waterproofing that becomes an integral part of the concrete structure. Unlike traditional barrier systems that function only at surfaces, crystalline waterproofing penetrates throughout the concrete mass, providing protection that cannot delaminate or deteriorate due to surface damage.

The self-healing properties of crystalline systems represent a paradigm shift in waterproofing philosophy. These systems can seal static hairline cracks up to 0.5 millimeters automatically when water is present, providing ongoing protection that adapts to normal structural movement and minor cracking that occurs during building service life.

Multi-Chemistry Approaches

Advanced waterproofing concrete structures now incorporate multiple chemistry types to address different water intrusion mechanisms and exposure conditions. Silane-siloxane systems provide excellent penetration into concrete substrates while maintaining breathability that prevents moisture entrapment within structural elements.

Silicate-based systems react chemically with concrete components to form permanent crystalline barriers that resist both water penetration and chemical attack. These systems are particularly effective for below-grade applications where hydrostatic pressure and aggressive soil conditions challenge conventional waterproofing approaches.

The integration of different chemical systems enables customized solutions that address specific project requirements and environmental conditions. This approach allows waterproofing professionals to optimize protection while considering factors including substrate conditions, exposure severity, and long-term maintenance requirements.

Advanced Sealant Technologies for Joint Systems

High-Performance Elastomeric Systems

Construction joint sealing represents a critical component of comprehensive waterproofing, requiring materials that accommodate structural movement while maintaining water resistance. Modern elastomeric sealants utilize advanced polymer chemistry to achieve exceptional elongation capabilities while resisting UV degradation and environmental aging.

Silyl modified polymer (SMP) sealants provide superior bonding strength and flexibility compared to traditional silicone systems. These materials maintain elastic properties across wide temperature ranges while offering enhanced durability and resistance to weathering that extends service life significantly.

Polyurethane sealant systems deliver exceptional adhesion and mechanical properties for demanding applications including structural glazing and high-movement joints. Advanced polyurethane formulations incorporate UV stabilizers and anti-aging additives that maintain performance throughout extended service periods.

Smart Sealant Integration

Innovative sealant applications incorporate sensors and monitoring capabilities that provide real-time feedback on joint performance and water infiltration risks. These smart systems enable predictive maintenance approaches that address potential failures before water damage occurs.

Self-healing sealant technologies utilize microencapsulated healing agents that activate when cracks develop, automatically sealing minor failures and extending service life. These systems provide backup protection that reduces maintenance requirements while ensuring continued water resistance.

Below-Grade Waterproofing Innovations

Integrated Membrane Systems

Below-grade waterproofing has evolved beyond simple sheet membranes to encompass integrated systems that combine multiple protection layers with drainage and moisture management components. These comprehensive approaches address hydrostatic pressure, soil chemicals, and root penetration through coordinated system design.

Thermoplastic and thermoset membrane technologies provide exceptional chemical resistance and durability for challenging below-grade conditions. Modern membrane systems incorporate reinforcement layers and protective systems that resist damage during backfilling operations while maintaining long-term performance.

The integration of drainage systems with waterproofing membranes creates comprehensive water management that reduces hydrostatic pressure loading while providing backup protection against membrane failures. These systems utilize specialized geocomposite materials that maintain drainage capacity while filtering soil particles.

Foundation Wall Protection

Innovative foundation waterproofing systems address the unique challenges of basement and below-grade construction through materials and methods specifically designed for hydrostatic pressure resistance. These systems must perform reliably for decades while withstanding soil movement, freeze-thaw cycling, and chemical exposure.

Crystalline foundation treatments penetrate concrete surfaces to create integral waterproofing that cannot be damaged by backfill operations or structural settlement. These systems provide permanent protection that eliminates the vulnerabilities associated with surface-applied membranes.

Bentonite-based systems utilize natural clay materials that swell when contacted by water, creating impermeable barriers that self-seal around penetrations and minor defects. These systems provide excellent backup protection and are particularly effective for challenging groundwater conditions.

Roofing and Above-Grade Applications

Advanced Liquid Applied Systems

Roofing waterproofing has been transformed by liquid applied systems that provide seamless protection over complex geometries and penetration details. These systems eliminate the seams and joints that represent failure points in traditional sheet membrane systems.

Polyurethane liquid applied membranes offer exceptional durability and UV resistance while accommodating structural movement and thermal cycling. Modern formulations incorporate rapid cure technologies that enable application during limited weather windows while ensuring complete cure and performance development.

Acrylic and silicone liquid systems provide cost-effective solutions for moderate exposure conditions while offering excellent reflectivity and energy performance benefits. These systems can be applied over various substrates and provide restoration capabilities for existing roof systems.

Green Roof Integration

Waterproofing concrete structures in green roof applications requires specialized systems that resist root penetration, chemical exposure from plant materials, and the unique loading conditions associated with growing media and vegetation.

Root barrier technologies utilize chemical and physical barriers to prevent plant root systems from penetrating waterproofing membranes while maintaining the flexibility and durability required for structural protection. These systems must perform reliably for extended periods without maintenance access.

The integration of waterproofing with drainage and growing media systems requires careful coordination to ensure that plant health requirements do not compromise structural protection. Modern green roof systems utilize layered approaches that separate waterproofing from growing media while providing necessary moisture management.

Quality Assurance and Testing Methodologies

Performance Verification Systems

Contemporary waterproofing projects incorporate advanced testing methodologies that verify system performance before final acceptance. Electronic leak detection systems can identify membrane defects and joint failures with precision that enables targeted repairs without system replacement.

Flood testing protocols provide definitive performance verification for critical applications including plaza decks and below-grade installations. These tests simulate actual service conditions while enabling evaluation of system performance under controlled conditions.

The integration of monitoring systems within waterproofing installations enables long-term performance tracking and predictive maintenance scheduling. These systems provide early warning of potential failures while documenting system performance throughout service life.

Installation Quality Control

Modern waterproofing installations utilize quality control protocols that ensure proper material application and system integration. Environmental monitoring during installation verifies that temperature, humidity, and substrate conditions meet manufacturer requirements for optimal performance.

Digital documentation systems create permanent records of installation procedures, material certifications, and performance testing results. This documentation provides valuable information for warranty administration and future maintenance planning while ensuring accountability throughout the installation process.

Future Technological Developments

Nanotechnology Integration

Emerging nanotechnology applications promise to enhance waterproofing concrete structures through materials that provide superior penetration and performance at molecular levels. Nano-sized particles can penetrate concrete pores more effectively while providing enhanced chemical resistance and durability.

Self-cleaning waterproofing surfaces utilize photocatalytic nanotechnology to break down organic contaminants and maintain surface integrity throughout service life. These technologies reduce maintenance requirements while ensuring continued performance in challenging environmental conditions.

Smart Material Applications

Future waterproofing systems will incorporate smart materials that respond to environmental conditions and provide adaptive protection. Shape-memory polymers could enable sealants that adjust their properties based on temperature and movement conditions automatically.

The integration of waterproofing systems with building automation and monitoring networks will enable comprehensive water management that coordinates multiple building systems to optimize performance while minimizing energy consumption and maintenance requirements.

The evolution of waterproofing concrete structures represents a fundamental advancement in building science that addresses the complex challenges of water management in modern construction. As these technologies continue to develop and integrate with broader building systems, they provide construction professionals with tools to create structures that maintain their integrity and performance throughout extended service lives while minimizing maintenance requirements and lifecycle costs. This technological progression ensures that buildings can meet the demanding performance requirements of contemporary construction while providing long-term value and reliability that define professional construction excellence.