The construction industry is experiencing a profound transformation, driven by rapid technological advancements. Edge computing is one of the transformative technologies enabling real-time data processing. The integration of edge computing in construction equipment allows heavy machinery and construction assets to operate more intelligently, autonomously, and efficiently. This lays the foundation for the next era of construction automation.

The Need for Edge Computing in Construction Equipment

Traditionally, construction equipment relied heavily on manual oversight and periodic maintenance schedules, often leading to inefficiencies, delays, and unforeseen breakdowns. As equipment becomes more complex—integrating sensors, IoT devices, and automation features—the amount of data generated has skyrocketed. The challenge is not just collecting data but making sense of it in real-time to inform operational decisions.

The conventional reliance on centralised cloud computing for data processing poses limitations, especially in remote and expansive construction sites where latency, bandwidth constraints, and connectivity issues can hamper performance. These limitations underscored the need for a more localised, responsive approach, hence the rise of edge computing.

Edge computing decentralises data processing by managing computation closer to the physical construction equipment. This setup enables machinery to instantly analyse sensor data, detect anomalies, optimise operations, and even perform autonomous actions without waiting for cloud-based responses.

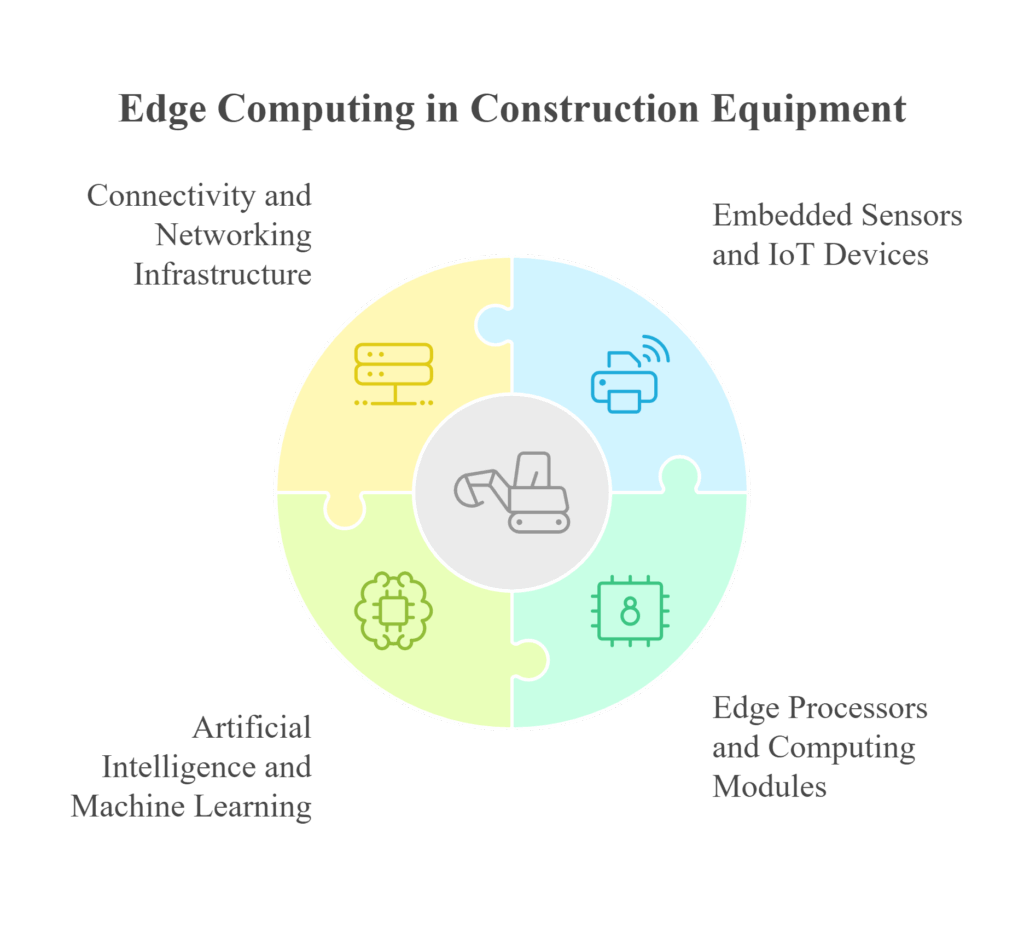

Core Technologies Powering Edge Computing in Construction Equipment

Edge computing’s impact on construction equipment depends on a suite of interconnected technologies, each contributing to a seamless, autonomous, and intelligent operation.

- Embedded Sensors and IoT Devices

Construction machinery, such as excavators, bulldozers, and cranes, are equipped with a range of sensors monitoring parameters like vibration, temperature, hydraulic pressure, operational speed, and environmental conditions. These sensors generate continuous streams of data vital for assessing equipment health, operational efficiency, and safety.

- Edge Processors and Computing Modules

At the core of edge computing are dedicated processors embedded directly within machinery or attached units, capable of handling data processing tasks locally. These modules are designed to operate reliably under harsh construction environments, withstanding dust, moisture, vibration, and temperature extremes. They perform initial data filtering, aggregating, and analysis, reducing the volume of data transmitted to central servers.

- Artificial Intelligence and Machine Learning

AI algorithms deployed at the edge analyse sensor data in real-time, identifying patterns indicative of potential faults or inefficiencies. Machine learning models are trained to recognize signatures of wear and tear that precede equipment failure, enabling predictive maintenance and autonomous operational adjustments.

- Connectivity and Networking Infrastructure

While edge computing transforming smart construction equipment reduces reliance on cloud data centers, robust local networking, using LTE/5G, Wi-Fi, or private wireless networks, is essential for seamless data exchange between equipment and central management systems. This infrastructure ensures continuous synchronization, remote monitoring, and command execution.

Advantages of Edge Computing Enabled Smart Construction Equipment

Integrating edge computing with construction equipment unlocks numerous benefits that directly influence project timelines, safety standards, and operational costs.

One of the most immediate benefits is the significant reduction in latency. Traditional cloud-based systems often encounter delays due to data transmission to centralized servers and back. In contrast, edge computing processes data locally, providing instant insights critical for real-time decision-making, especially in dynamic construction environments where delays can lead to accidents or costly errors.

Predictive maintenance becomes more effective and timelier with edge computing. Sensors embedded in equipment detect early signs of wear or malfunction, enabling maintenance teams to schedule repairs preemptively. This shift from reactive to proactive maintenance reduces downtime, extends asset lifespan, and minimizes costly emergency repairs.

Operational efficiency is enhanced through autonomous decision-making. For example, machinery equipped with AI at the edge can adjust its operation based on real-time data—optimising fuel consumption, adjusting operation speeds, or switching modes to adapt to environmental conditions or project requirements.

Furthermore, edge computing transforming smart construction equipment facilitates better resource allocation and project management by providing granular, real-time data on equipment performance and location. This data empowers project managers to optimise workflows, allocate resources more efficiently, and improve overall project timelines.

Implementation Challenges in Edge-Powered Construction Equipment

Despite its transformative potential, deploying edge computing in construction equipment presents several challenges that require strategic planning and technical expertise.

The environmental conditions on construction sites are extreme—dust, mud, vibration, humidity, and temperature fluctuations pose persistent threats to sensitive electronic equipment. Deploying ruggedized, industrial-grade hardware capable of withstanding these conditions is essential but often comes at increased costs.

Connectivity remains a significant concern, especially in remote or underground sites where reliable high-bandwidth communication channels are limited. Although edge processing reduces reliance on continuous cloud connectivity, some level of communication is necessary for updates, control commands, and data backups. Therefore, investing in advanced wireless and satellite communication infrastructure becomes critical.

Data management and quality control are also crucial; sensors must be calibrated correctly, and data must be cleansed and validated to ensure accuracy for AI models. Inconsistent or noisy data can lead to false positives or missed detections, impacting decision-making reliability.

Cybersecurity risks increase with distributed edge devices that operate semi-autonomously. Protecting these systems against hacking, malware, or data breaches is vital, requiring robust security protocols, regular updates, and intrusion detection mechanisms.

Change management constitutes another hurdle, as workforce readiness and acceptance of autonomous or semi-autonomous systems can vary. Training personnel to operate, maintain, and troubleshoot edge systems is necessary to ensure smooth adoption.

Finally, the cost of initial deployment, including hardware, software, and infrastructure upgrades, can be substantial, especially for older or existing equipment that requires retrofitting.

The Road Ahead for Edge Computing in Construction

The future of edge computing in the construction industry is poised for exponential growth, driven by innovations in hardware, connectivity, and AI algorithms. As 5G networks become more widespread, construction sites will benefit from higher bandwidths, lower latency, and more reliable real-time communication, making edge systems even more effective.

Emerging advancements in sensor technology will produce smarter, self-calibrating sensors capable of providing richer data streams with minimal maintenance. These sensors will facilitate better predictive analytics, improving the accuracy of equipment failure forecasts and operational insights.

Additionally, integrating AI at the edge will unlock even more autonomous capabilities. Construction equipment will increasingly operate with minimal human supervision, dynamically adjusting to environmental variables and project demands. Robotics, drones, and autonomous vehicles will work seamlessly with edge computing cores embedded within the infrastructure.

Cloud and edge systems will become more integrated, forming hybrid models where critical real-time processing occurs at the edge, while broader data analysis and reporting are handled in the cloud. This synergy will enhance overall operational resilience, data security, and scalability.

Furthermore, industry-wide standards and regulations around edge device security, data privacy, and interoperability will evolve, guiding deployment practices and ensuring safety across diverse construction environments.

Conclusion: Embracing an Edge-Centric Future

The adoption of edge computing in smart construction equipment marks a pivotal shift toward greater automation, safety, and operational efficiency in the construction sector. By processing critical data locally at the machinery level, companies can achieve immediate insights, autonomous operation, and resilient infrastructure management, even in remote or harsh environments.

This technological evolution addresses many longstanding challenges—delays in decision-making, equipment failures, safety hazards, and resource wastage by providing real-time analytics and autonomous capabilities. As hardware becomes more rugged, connectivity more robust, and AI algorithms more sophisticated, the potential applications will only expand. Construction firms that proactively invest in edge computing technologies will position themselves at the forefront of digital transformation, unlocking new levels of productivity and safety standards.