3D Printing the Future: Additive Concrete Structures on the Jobsite

The construction landscape is experiencing a transformative revolution as 3D printed concrete structures move from experimental prototypes to practical construction solutions. This additive manufacturing approach is fundamentally changing how the industry conceptualizes design, construction speed, and architectural possibilities. As projects worldwide demonstrate the viability of large-scale concrete printing, the technology is establishing itself as a cornerstone of next-generation construction methodology.

The Evolution of Additive Manufacturing in Construction

Additive construction with concrete represents a paradigm shift from traditional subtractive and formwork-dependent building methods. The technology enables the precise, layer-by-layer deposition of concrete materials according to digital designs, eliminating the need for conventional formwork while dramatically reducing material waste and construction timelines.

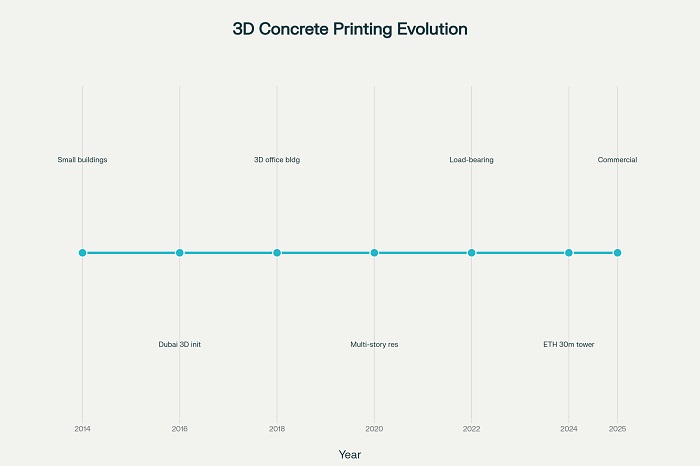

The sophistication of 3D printed concrete structures has evolved rapidly from simple demonstration walls to complex architectural elements. ETH Zurich’s Tor Alva project, standing 30 meters tall with 36 ornamented and branching columns, represents the current pinnacle of load-bearing 3D concrete printing. This world’s tallest 3D-printed tower demonstrates that additive manufacturing can now handle structural applications at unprecedented scales.

Revolutionary Printing Technologies

Extrusion-Based Systems

The most prevalent approach to 3D printed concrete structures utilizes extrusion-based systems that push specially formulated concrete through controlled nozzles. These systems must balance competing requirements: the material must remain fluid enough for extrusion while developing sufficient strength immediately after deposition to support subsequent layers.

Gantry-style printers offer exceptional precision for moderate-scale projects, providing consistent layer adhesion and dimensional accuracy. These systems excel in controlled environments where repeatability and quality control are paramount. For larger projects, robotic arm systems provide greater flexibility in geometry and can access complex shapes that would challenge traditional gantry configurations.

Mobile printing units are revolutionizing on-site construction by bringing additive manufacturing directly to job locations. These systems can produce up to 75 cubic meters per hour while maintaining strict noise, dust, and water restrictions that make them suitable for urban construction environments.

Advanced Material Systems

The success of 3D printed concrete structures depends critically on specialized concrete formulations that exhibit unique rheological properties. These materials must demonstrate thixotropic behavior, flowing under the shear forces of pumping and extrusion while maintaining shape stability once deposited.

Modern printable concrete incorporates advanced admixture packages that provide precise control over workability windows and strength development. Accelerating admixtures enable proper interlayer bonding while maintaining construction schedule requirements. Some formulations achieve required early strength within 16-hour demolding cycles, matching the performance expectations of conventional concrete construction.

The integration of fiber reinforcement within printable concrete enhances tensile properties and crack resistance. Synthetic and natural fibers distributed throughout the mix provide multidirectional reinforcement that complements the layer-by-layer construction process inherent in 3D printed concrete structures.

Structural Engineering Innovations

Reinforcement Integration

One of the most significant technical challenges in 3D printed concrete structures involves reinforcement integration. Traditional steel reinforcement requires innovative approaches that accommodate the additive manufacturing process while maintaining structural performance.

Post-installed reinforcement systems have proven effective for load-bearing applications. Stainless steel reinforcement bars can be inserted through preformed channels in printed concrete, with specialized mortars providing bond development. This approach has enabled the construction of structurally viable 3D printed concrete structures that meet conventional building code requirements.

Embedded reinforcement strategies involve the integration of steel cables, tendons, or mesh systems during the printing process. These approaches require precise coordination between material deposition and reinforcement placement but can achieve superior structural performance by eliminating discontinuities between printed layers and reinforcement systems.

Structural Performance Validation

The anisotropic properties of 3D printed concrete structures necessitate specialized testing protocols that account for layer interfaces and printing orientation effects. Modified slant shear tests have been developed to evaluate interlayer bond strength at various angles, providing crucial data for structural design applications.

Full-scale testing of printed structural elements validates computational models and provides confidence for engineering applications. Load testing of complete columns and structural assemblies demonstrates that properly designed 3D printed concrete structures can achieve performance comparable to conventionally constructed elements.

Architectural Design Freedom

The elimination of formwork constraints in 3D printed concrete structures opens unprecedented architectural possibilities. Complex geometries that would be prohibitively expensive or impossible with conventional construction become readily achievable through additive manufacturing.

Parametric design tools enable architects to create structures that optimize material distribution according to structural requirements. This “form follows force” approach can reduce material consumption while creating visually striking architectural elements that demonstrate the structural logic inherent in their geometry.

The ability to vary cross-sections continuously throughout a printed element enables optimization strategies that would be impossible with conventional construction. Structural elements can transition seamlessly between different geometric configurations, concentrating material where stresses are highest while minimizing material use in less critical regions.

Project Execution and Quality Control

Digital Workflow Integration

Successful 3D printed concrete structures require seamless integration between design, fabrication, and construction phases. Building Information Modeling (BIM) systems now incorporate specialized modules for additive construction that enable direct translation from architectural models to printer control systems.

Real-time monitoring during printing operations ensures quality control and enables immediate intervention when deviations occur. Sensor systems monitor layer thickness, material consistency, and printing speed to maintain dimensional accuracy and structural properties throughout the construction process.

Construction Site Integration

The integration of 3D printing operations with conventional construction activities requires careful coordination and specialized logistics. Temporary facilities must accommodate printing equipment while maintaining access for traditional trades and material delivery.

Site preparation for 3D printed concrete structures differs significantly from conventional construction, requiring level printing surfaces and adequate clearances for printing equipment movement. Utility integration must be planned from design phases to ensure compatibility with additive manufacturing workflows.

Economic and Productivity Impacts

The economic advantages of 3D printed concrete structures extend beyond simple cost comparisons to encompass productivity improvements and schedule acceleration. Elimination of formwork construction and stripping operations can reduce project timelines by 30-50% for suitable applications.

Labor productivity improvements stem from automation of material placement operations and reduction of skilled trade requirements for complex geometric elements. Single operators can manage printing operations that would traditionally require multiple craftspeople using conventional construction methods.

Material efficiency gains result from precise material placement without waste associated with formwork construction and concrete overages. The ability to optimize material distribution throughout structural elements can achieve 20-30% material savings compared to conventional rectangular sections.

Sustainability and Environmental Impact

3D printed concrete structures contribute to sustainability goals through multiple pathways beyond simple material reduction. The precision of additive manufacturing enables the use of optimized concrete mixes that may incorporate higher percentages of recycled materials or industrial byproducts.

The elimination of formwork materials reduces waste streams associated with temporary construction elements. Reusable formwork systems are eliminated entirely, while single-use formwork materials such as plywood and lumber are not required for printed elements.

Energy consumption for 3D printed concrete structures can be lower than conventional construction due to reduced transportation requirements for formwork materials and the elimination of energy-intensive forming and stripping operations.

Future Technological Developments

Emerging technologies promise to further enhance the capabilities of 3D printed concrete structures. Multi-material printing systems will enable the simultaneous deposition of structural concrete, reinforcement elements, and utility conduits in integrated operations.

Robotic finishing systems are being developed to provide surface treatments and architectural details that complement the additive manufacturing process. These systems can apply coatings, create surface textures, and install architectural elements as integrated parts of the printing workflow.

Advanced concrete formulations incorporating self-healing capabilities and enhanced durability properties will extend the service life of 3D printed concrete structures while reducing maintenance requirements throughout their operational lives.

The convergence of additive manufacturing with other emerging technologies including artificial intelligence, Internet of Things sensors, and advanced materials science continues to expand the possibilities for 3D printed concrete structures. As these technologies mature and integrate, they promise to establish additive construction as a mainstream approach that combines design freedom, construction efficiency, and environmental responsibility in unprecedented ways.

The transformation toward 3D printed concrete structures represents more than technological innovation; it embodies a fundamental reimagining of how buildings and infrastructure can be conceived, designed, and constructed. This evolution positions the construction industry to meet growing global building needs while achieving new standards of efficiency, sustainability, and architectural expression.