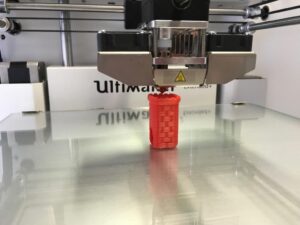

Industrial 3D printing is no longer just for making prototypes. These days, it is helping many industries build strong, detailed, and finished parts at a fast rate. One company in Canada stands out for its high-tech solutions and reliable production.

They’ve made it easier for businesses to get parts quickly, in small or large numbers. As a result, many Canadian businesses rely on the Anubis 3d printing service for their industrial 3D printing needs. In this article, we’ll discuss the printing solutions this company offers its customers.

Selective Laser Sintering (SLS)

Selective Laser Sintering, or SLS, is a method that uses a laser to melt powdered plastic into a solid piece. Layer by layer, the laser builds the item from the ground up. SLS is faster and cleaner than other methods because it doesn’t need support structures. Parts made using SLS are strong, stiff, and can resist many chemicals.

This is why it is used for tools, covers, and even some final-use products. In addition, SLS is great for designs that are hard to make with older methods like injection moulding. You can read this article to see how SLS compares to another additive manufacturing method.

Furthermore, SLS also supports finishing options like painting, coating, and even over-moulding. The results can look like CNC-milled parts, but they are made much faster.

Stereolithography (SLA)

Stereolithography, or SLA, is another smart option. Light is used in this method to harden a special resin into solid layers. As a result, it can produce smooth surfaces, sharp edges, and very fine details.

SLA is often used to make parts that need to look good and match accurately. Models, cases, and low-use mechanical parts are often made using this method. It is a great choice for small parts that fit into bigger systems because of its tight tolerances.

Parts made with SLA are strong enough to be machined, moulded, or cast. It is often used to make moulds for metal or silicone items. Moreover, a lot of clients have used SLA to test designs before mass production. You can visit https://blog.goldsupplier.com/ to learn more about the SLA process.

3D Manufacturing Hybrid Solutions

Some projects need more than just one method, which is why hybrid solutions are useful. It combines both 3D printing and more traditional means, such as laser cutting, casting, or machining. This is helpful when you only need to 3D print some parts of a design.

This option is useful for making parts that require a combination of looks, strength, and speed. For example:

- For flat pieces, use laser cutting.

- Add parts that were made with 3D printing to finish the design.

- Smooth the surface and make it easier to hold with over-moulding.

CT scans and 3D scanning are also tools used during hybrid projects. When you need to copy a part or check its quality, these tools can help. You can scan a real part, save it as a file, and then print a new one with only a few small changes.

Low Volume Production

Some companies don’t need thousands of pieces of the same part, and that’s where low-volume production comes in. With this service, customers can make from a few dozen to a few hundred parts at once. This method allows companies to save money because it doesn’t need expensive moulds or a long setup time.

Low-volume production helps in four main ways:

- Quickly try out new ideas.

- Make changes to the design without spending extra money.

- Launch products quicker.

- Test the market before full production.

Many companies use low-volume production to make their products available in the market before their competitors. Before other people even finish designing, they can test, improve, and launch the product. This is a good way to stay ahead of the competition and reduce your risk.

You can check out this post to discover more reasons why your business needs low-volume production runs.

Conclusion

Canadian companies are using industrial 3D printing to make faster and more useful products. Whether it’s SLS, SLA, hybrid services, or low-volume runs, these solutions are ready for real-world use. Companies like Anubis 3DA 3D printing service like Anubis can help you get parts that are accurate, strong, and specifically made for the project.

These companies use the best aspects of both new and old methods to help customers get what they want quickly and without delays or waste. It’s clear that smart 3D printing will continue to help companies stay strong and flexible as demand grows.