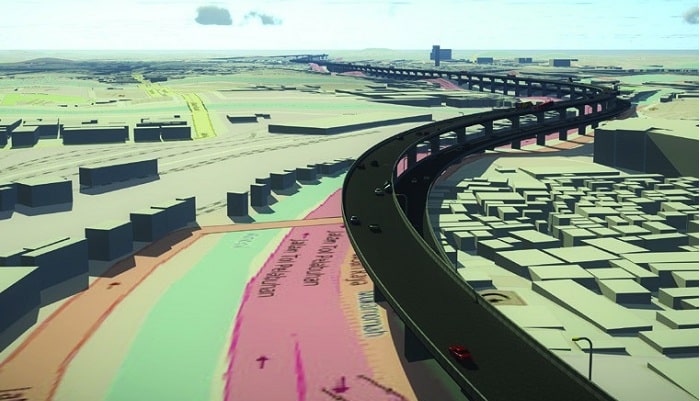

When PT. Wijaya Karya (WIKA), an Indonesia-based company that provides construction, mechanical and electrical services to the civil construction industry, was contracted to design the Design and Build Harbour Road 2 Project in North Jakarta, Indonesia, budgeted at USD $530 million, the project team quickly realized that traditional 2D design methods would not deliver the large and complex 8.95-kilometer toll road development on time and within budget.

“The total volume of the concrete used in this project is a quarter of that of the Giza pyramid,” said Fery Safaria, engineering manager at WIKA. “The total scale of the project is about four times that of Vatican City.”

The project was sorely needed as residents of Ancol and Pluit needed a more efficient way to travel between the cities, with the existing path a frequently congested patchwork of existing toll roads, interchanges, flyovers, railroads and waterways.

Due to limited space, heavy traffic and numerous intersection points, WIKA determined that the development needed to include a 3.95-kilometer double-decker bridge along the Ancol River that will become the longest in the world. However, the Indonesian government mandated the organization should avoid placing piers in the water that could negatively impact the ecosystem and existing river traffic. The project team also had to avoid various underground gas pipelines, water pipes and fiber optic cables as well as above-ground buildings.

Moreover, WIKA faced a strict deadline to complete Harbour Road 2 before the start of the FIFA 2021 U-20 World Cup being held at nearby Jakarta International Stadium. The new highway is expected to ease traffic to and from the facility. Aside from completing the project prior to the tournament, Harbour Road 2 will improve access to the airport and reclamation islands being developed by the government. Lastly, the new highway will greatly improve economic activity and tourism in the area.

Saving Time Using a BIM Methodology

To design such a complex road system and meet the aggressive schedule, WIKA transitioned from a traditional 2D design method and adopted a 3D BIM methodology. The project team began the conversion with image capture via unmanned aerial vehicles, using generalized predictive control to produce a reality mesh within ContextCapture. The project team was able to photograph and process 166 hectares of land in just 15 days—roughly 6 times faster than traditional surveying methods.

Throughout the process, Navigator facilitated communication and collaboration among teams and stakeholders as well as allowing designers to access running costs and project data from the office, remotely or in the field. WIKA estimated that using BIM methodologies reduced the time needed for communication and inspection by as much as 30 percent, compared to previously deployed methods. OpenRoads helped WIKA review the alignment of the main road, ramps and approaching structures, while OpenBridge allowed the team to iterate pier positions and heights based on real-world conditions. Careful pier positioning helped the project team avoid placing them in the river wherever possible and lowered the risk of flooding in the surrounding area.

WIKA’s design iteration using OpenRoads, OpenBridge and gINT avoided 1,600 meters of costly waterway foundation work and reduced the design process by 25 days.