Innovations Transforming Lifting Equipment Construction

The construction industry stands at a pivotal moment where technological advancement intersects with operational necessity. As projects grow more complex and safety regulations become increasingly stringent, the lifting equipment sector has responded with innovations that fundamentally reshape how heavy loads are handled on modern construction sites. These developments represent far more than incremental improvements—they constitute a technological revolution that enhances safety protocols, operational efficiency, and environmental responsibility across the entire construction ecosystem.

The Digital Intelligence Revolution

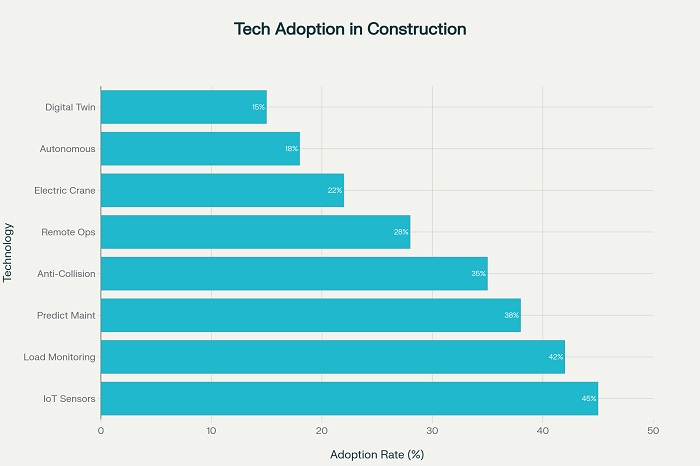

Modern lifting equipment has evolved from purely mechanical systems into sophisticated digital platforms. Smart cranes now incorporate Internet of Things sensors throughout their structural components, creating continuous data streams that inform every operational decision. These sensors monitor load weight distribution, wind conditions, structural stress points, and operational parameters simultaneously, providing crane operators with unprecedented situational awareness. The integration of artificial intelligence algorithms allows these systems to analyze patterns, predict potential issues before they manifest, and optimize lifting operations in real time.

The transformation extends beyond individual machines. Advanced telematics systems now enable fleet managers to monitor equipment performance across multiple job sites from centralized control rooms. These systems track utilization patterns, identify maintenance requirements before mechanical failures occur, and provide detailed analytics on operational efficiency. Construction companies implementing these technologies report significant reductions in unplanned downtime and maintenance costs, with some experiencing improvements exceeding sixty percent in equipment availability.

Real-time monitoring capabilities have revolutionized crane management. Operators receive instant feedback on load capacities at specific boom angles and radii, while automatic systems can detect when operations approach dangerous thresholds. Modern load moment indicators integrate with crane control systems to prevent potentially hazardous situations by automatically limiting movements that would exceed safe operating parameters. This integration of monitoring and control represents a fundamental shift from reactive to proactive safety management.

Autonomous and Semi-Autonomous Systems

The construction industry has begun embracing autonomous lifting technologies that promise to reshape operational workflows. Self-positioning systems utilize GPS and sophisticated sensor arrays to navigate construction sites with minimal human intervention. These systems can identify optimal crane placement locations by analyzing ground conditions, calculating load paths, and assessing clearance requirements automatically. The technology reduces setup time significantly while improving positioning accuracy.

Anti-collision systems represent another critical autonomous innovation in innovations in lifting equipment construction. On sites where multiple cranes operate in proximity, these systems continuously calculate the three-dimensional positions of all equipment, predicting potential collision scenarios before they develop. Advanced implementations use LiDAR technology combined with computer vision to create detailed spatial maps of construction sites, enabling cranes to coordinate movements automatically and avoid dangerous situations. Construction projects utilizing these systems have documented substantial reductions in equipment damage and near-miss incidents.

Semi-autonomous features are becoming standard on premium lifting equipment. Load sway control systems use accelerometers and sophisticated algorithms to dampen unwanted oscillations during lifting operations, particularly valuable when moving loads in windy conditions or across significant horizontal distances. Automatic hook positioning reduces operator workload by guiding lifting hooks to predetermined locations with centimeter-level precision. These assistive technologies allow operators to focus on situational awareness and strategic decision-making rather than constant manual adjustments.

Sustainable Power Systems and Environmental Innovation

Environmental considerations have driven remarkable innovations in lifting equipment power systems. Electric and hybrid cranes have transitioned from experimental concepts to commercially viable alternatives to traditional diesel-powered equipment. Modern electric cranes achieve comparable performance to conventional models while eliminating on-site emissions entirely. Battery technology advances have extended operational runtimes, with some electric cranes now capable of working full shifts on single charges.

Hybrid systems offer particular advantages for construction environments. These cranes utilize diesel engines for transportation and setup, then switch to battery-electric operation for actual lifting work. The approach eliminates exhaust emissions and noise pollution during crane operation while maintaining the flexibility of conventional equipment. Energy efficiency improvements are substantial, with hybrid cranes demonstrating system efficiencies approaching eighty-five percent compared to approximately thirty percent for diesel-only systems. The reduced fuel consumption translates directly to lower operating costs and decreased carbon footprints.

Regenerative technologies further enhance sustainability. Advanced cranes now capture energy during lowering operations, converting gravitational potential energy into electrical power that recharges batteries or feeds back into site power systems. This capability can reduce overall energy consumption by significant margins, particularly on projects involving repetitive lifting cycles. Construction companies increasingly recognize that sustainable equipment choices contribute to both environmental goals and bottom-line performance.

Digital Twin Technology and Predictive Maintenance

Digital twin technology has emerged as a transformative tool for managing lifting equipment throughout its operational lifecycle. These virtual replicas mirror physical cranes in real time, incorporating sensor data to create dynamic models that reflect actual equipment conditions. Engineers can monitor structural health, analyze performance patterns, and simulate operational scenarios without interrupting active construction work. The technology enables maintenance teams to identify developing issues with remarkable accuracy, often detecting problems weeks before they would manifest as operational failures.

Predictive maintenance capabilities built on digital twin platforms demonstrate accuracy levels exceeding eighty percent in forecasting maintenance requirements. By analyzing vibration patterns, temperature variations, hydraulic pressures, and electrical parameters, these systems identify component degradation before it progresses to failure. Maintenance can be scheduled during planned downtime rather than occurring as emergency repairs, significantly reducing both direct costs and project delays. The approach represents a fundamental evolution from reactive maintenance toward condition-based strategies that optimize equipment reliability and operational availability.

Three-dimensional modeling combined with sensor data provides unprecedented insight into crane structural integrity. Load distribution analysis identifies areas experiencing excessive stress, allowing engineers to adjust operational parameters or schedule reinforcement before structural issues develop. The combination of physical monitoring and virtual modeling creates a comprehensive understanding of equipment health that was previously unattainable.

Enhanced Safety Through Advanced Engineering

Safety innovations in lifting equipment construction extend beyond digital systems to encompass fundamental engineering improvements. Modern cranes incorporate redundant safety systems that provide multiple layers of protection. Dual-circuit control systems ensure that critical safety functions remain operational even if primary systems fail. Structural designs now account for dynamic loading scenarios with greater sophistication, incorporating finite element analysis to optimize strength while minimizing weight.

Operator assistance technologies have evolved substantially. Advanced cab designs incorporate ergonomic improvements that reduce operator fatigue during extended operations. Multi-camera systems provide comprehensive views of lifting zones, eliminating blind spots that previously required ground personnel for verification. Augmented reality displays overlay critical information directly onto operator viewing windows, presenting load data, clearance measurements, and safety alerts without requiring operators to divert attention from lifting operations.

Emergency response capabilities have improved dramatically. Modern cranes feature sophisticated descent control systems that can safely lower loads even during power failures or hydraulic system malfunctions. Automatic parking brake systems engage immediately when abnormal conditions are detected, preventing uncontrolled movements. Wind speed monitoring integrated with operational controls can automatically limit or suspend crane operations when conditions exceed safe thresholds, removing subjective decision-making from critical safety judgments.

Future Implications and Industry Transformation

The convergence of mechanical engineering excellence, digital intelligence, and environmental responsibility continues driving innovations in lifting equipment construction. These technologies collectively represent not merely improvements to existing capabilities but fundamental transformations in how construction sites operate. Projects implementing these advanced systems demonstrate measurably superior safety records, improved productivity metrics, and reduced environmental impacts.

As technology continues advancing and costs decrease through wider adoption, these innovations will transition from competitive advantages to industry standards, establishing new benchmarks for construction excellence worldwide. The construction industry stands poised for unprecedented transformation as lifting equipment becomes increasingly intelligent, sustainable, and safe.