Next-Gen Floors & High-Tolerance Slabs: Robotics & Precision Pouring

The construction industry’s pursuit of precision and efficiency has reached new heights with the integration of robotic concrete flooring systems and advanced precision pouring technologies. These innovations are transforming traditional concrete placement methods, delivering unprecedented accuracy in slab tolerances while dramatically improving construction speed and quality. As projects demand ever-higher performance standards, robotic concrete flooring represents the evolution from craft-based to precision-engineered construction methodologies.

The Precision Imperative in Modern Construction

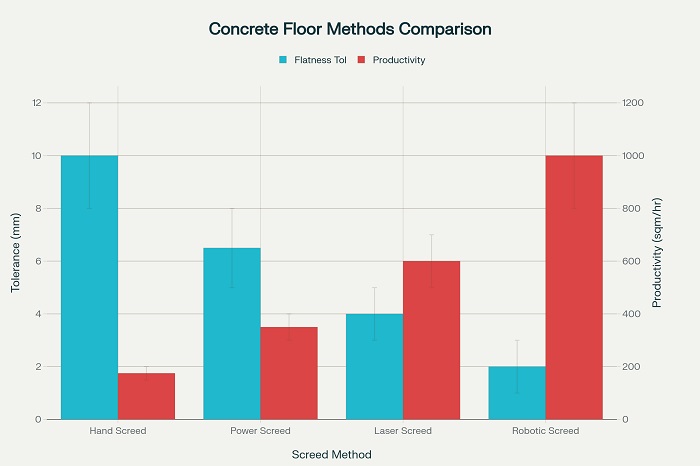

Contemporary construction projects require concrete slabs that meet increasingly stringent tolerance specifications. Modern warehouse facilities, data centers, and manufacturing facilities demand floor flatness tolerances measured in millimeters rather than centimeters. Traditional manual screeding and finishing methods struggle to consistently achieve these specifications across large areas, creating bottlenecks in project delivery and quality assurance.

The economic implications of precision flooring extend far beyond initial construction costs. Facilities with superior floor tolerances enable more efficient material handling systems, reduce equipment wear, and improve operational productivity throughout their service lives. These performance requirements have driven the development of robotic concrete flooring systems that can deliver precision unattainable through conventional methods.

Revolutionary Robotic Placement Systems

Automated Screeding Technologies

Robotic screeding systems represent a quantum leap beyond traditional manual methods, utilizing laser-guided control systems to maintain precise elevations across extensive concrete pours. These systems incorporate advanced sensors that continuously monitor surface elevation and automatically adjust screed height to maintain specification compliance.

Three-dimensional laser guidance systems enable robotic concrete flooring equipment to follow complex floor profiles with unprecedented accuracy. The integration of Global Positioning System (GPS) technology with laser levels provides absolute positioning reference that ensures consistent results regardless of pour size or geometric complexity.

Self-propelled robotic screeds can traverse concrete surfaces while material is still plastic, eliminating the need for manual labor in hazardous conditions while delivering superior surface regularity. These systems typically achieve flatness tolerances within 3mm across 3-meter spans, representing significant improvements over conventional screeding methods.

Intelligent Material Distribution

Advanced robotic concrete flooring systems incorporate intelligent material distribution capabilities that optimize placement patterns and minimize segregation. Programmable placement heads can vary discharge rates and locations according to predetermined algorithms that account for material flow characteristics and structural requirements.

Real-time monitoring of concrete properties enables dynamic adjustment of placement parameters to maintain consistency throughout large pours. Sensors measuring temperature, slump, and workability provide feedback that allows robotic systems to adapt to changing material conditions automatically.

The precision of robotic placement systems enables the use of optimized concrete mixes that might be difficult to handle with conventional methods. Higher-strength, lower-slump mixes that provide superior durability and long-term performance become practical when placed with robotic concrete flooring equipment.

Advanced Finishing Technologies

Robotic Power Troweling

The integration of robotics into concrete finishing operations has revolutionized surface preparation and quality control. Robotic power trowels utilize programmed path planning to ensure complete coverage while maintaining consistent pressure and speed across entire slab surfaces.

Automated troweling systems eliminate human variability in finishing operations, delivering uniform surface textures and densification that enhance durability and wear resistance. These systems can operate continuously without fatigue, maintaining consistent quality throughout extended finishing operations.

Multi-pass troweling programs optimize surface development by automatically adjusting blade pitch and rotation speed according to concrete maturity. Advanced systems monitor surface conditions in real-time and modify finishing parameters to achieve optimal results regardless of environmental conditions or material variations.

Precision Edge Forming

Robotic concrete flooring systems incorporate advanced edge forming technologies that eliminate manual labor while delivering precise edge profiles. Automated edge forms utilize hydraulic or mechanical adjustment systems that maintain exact positioning throughout concrete placement and finishing operations.

The integration of edge forming with robotic screeding systems ensures seamless transitions between slab areas and eliminates the irregularities commonly associated with conventional construction joints. These systems can accommodate complex geometries including curves, angles, and elevation changes with minimal setup time and superior accuracy.

Quality Control and Measurement Systems

Real-Time Surface Monitoring

Contemporary robotic concrete flooring installations incorporate sophisticated measurement systems that provide continuous quality feedback throughout construction operations. Laser scanning systems generate detailed surface maps that identify deviations from specification requirements before finishing operations are complete.

Three-dimensional surface analysis enables immediate corrective action when tolerances are exceeded, preventing costly remedial work and schedule delays. Real-time data visualization provides construction teams with immediate feedback on surface quality and allows for process adjustments during active operations.

Statistical process control algorithms analyze surface measurement data to identify trends and predict potential quality issues before they impact final results. This proactive approach to quality management represents a fundamental shift from reactive inspection to predictive quality assurance.

Documentation and Verification

Robotic concrete flooring systems generate comprehensive documentation of surface quality that exceeds traditional inspection methods. Automated measurement systems create permanent records of actual achieved tolerances that provide objective verification of specification compliance.

Digital documentation systems integrate with project management software to provide real-time reporting of quality metrics and construction progress. This integration enables project stakeholders to monitor performance and make informed decisions throughout construction operations.

The precision of robotic measurement systems enables the development of performance-based specifications that focus on actual functional requirements rather than prescriptive construction methods. This approach allows contractors to optimize methods while ensuring that performance objectives are achieved.

Productivity and Economic Advantages

Construction Speed Improvements

Robotic concrete flooring systems deliver substantial productivity improvements through automation of labor-intensive operations and elimination of rework. Typical installations achieve placement rates 50-100% higher than conventional methods while maintaining superior quality standards.

The elimination of manual screeding and finishing operations reduces labor requirements and enables optimal crew utilization. Skilled workers can focus on setup, quality control, and oversight functions while robotic systems handle repetitive placement and finishing tasks.

Continuous operation capabilities enable extended work cycles that maximize daily productivity. Robotic systems can operate effectively during night shifts and extended hours without quality degradation, enabling accelerated project schedules when required.

Long-Term Performance Benefits

The superior precision achieved through robotic concrete flooring delivers long-term performance advantages that justify initial equipment investments. Facilities with high-tolerance floors experience reduced maintenance costs, improved operational efficiency, and extended service lives.

Enhanced surface regularity reduces wear on material handling equipment and improves safety conditions for workers and equipment operators. These operational benefits compound over facility lifespans to deliver substantial returns on initial precision investments.

The durability improvements associated with consistent finishing and optimal surface densification reduce lifecycle maintenance requirements and extend service intervals for floor treatments and overlays.

Integration with Smart Construction Technologies

IoT Connectivity and Data Analytics

Modern robotic concrete flooring systems incorporate Internet of Things (IoT) connectivity that enables integration with broader construction management systems. Real-time data transmission provides project managers with immediate access to quality metrics, productivity measurements, and equipment performance indicators.

Machine learning algorithms analyze historical performance data to optimize robotic operating parameters for specific project conditions and requirements. This continuous improvement approach enhances system performance over time and enables predictive maintenance scheduling.

Cloud-based data storage and analysis platforms enable benchmarking of performance across multiple projects and identification of best practices that can be applied to future installations.

Building Information Model Integration

The integration of robotic concrete flooring systems with Building Information Modeling (BIM) platforms enables seamless translation from design intent to construction execution. Digital models provide precise geometric data that guides robotic operations and ensures compliance with architectural and structural requirements.

Real-time feedback from robotic systems updates BIM models with as-built conditions, creating accurate documentation for facility management and future renovation planning. This bidirectional data flow ensures that digital models reflect actual constructed conditions rather than design intent alone.

Future Technological Developments

Artificial Intelligence Integration

Emerging artificial intelligence applications promise to further enhance robotic concrete flooring capabilities through advanced pattern recognition and predictive optimization. AI systems can analyze complex data sets from multiple sensors to identify optimal processing parameters for specific conditions.

Machine learning algorithms will enable robotic systems to adapt automatically to changing conditions and learn from experience to continuously improve performance. These capabilities will reduce setup time and eliminate manual parameter adjustment requirements.

Advanced Sensor Technologies

Next-generation sensor systems will provide enhanced feedback for robotic concrete flooring operations, including real-time material property measurement and predictive surface quality assessment. These sensors will enable more precise control of finishing operations and improved prediction of final surface characteristics.

The integration of multiple sensor types including thermal, acoustic, and electromagnetic systems will provide comprehensive monitoring capabilities that ensure optimal concrete development and surface preparation.

The evolution of robotic concrete flooring represents a fundamental transformation in how the construction industry approaches precision and quality control. As these technologies continue to mature and integrate with broader digital construction ecosystems, they promise to establish new standards for what is achievable in concrete construction while simultaneously improving productivity, safety, and long-term performance. This technological advancement ensures that construction projects can meet the demanding requirements of modern facilities while achieving new levels of efficiency and precision that define the future of the industry.