The construction industry has historically been a significant contributor to global carbon emissions, resource depletion, and environmental degradation. However, there has been a paradigm shift due to an international push towards sustainability, climate change mitigation, and resource efficiency. The shift is radically transforming the face of building materials, resulting in innovative developments that hold the promise of cleaner, greener, and more durable infrastructure.

Sustainable building materials have come a long way since basic recycled content or low-energy production processes. They now include a wide range of high-end composites, bio-based products, and intelligent solutions that maximize advanced technologies and scientific understanding. These innovations not only seek to minimize environmental effects but also to maximize the durability, energy efficiency, and overall lifecycle performance of buildings. As this industry transitions towards a more sustainable future, it is important for architects, engineers, developers, and policymakers to recognize these most recent advances.

The Evolution of Sustainable Building Materials

Historically, sustainable building materials used simple solutions including recycled steel, low VOC paints, or bamboo. While these materials contributed to improved environmental outcomes, they often lacked the performance characteristics required for modern construction demands. In addition, their implementation was at times slowed by greater expense or unfamiliarity.

The most recent innovations are now being fueled by improvements in material science, digital fabrication, and biological sciences. These are opening doors to the production of materials that are not only sustainable but also high-performance, resilient, and economical at scale. This transformation represents an integrated strategy—combining sustainability with innovation—to shape the construction future.

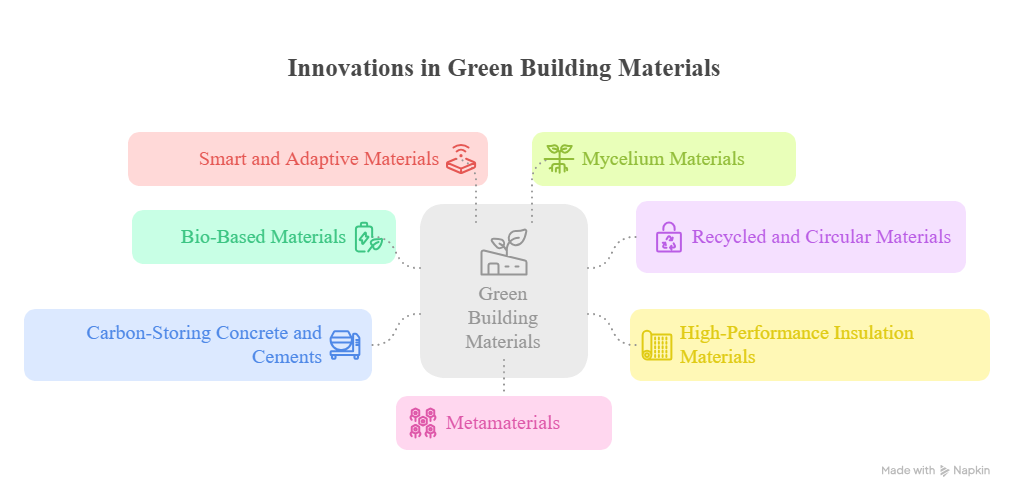

Cutting-Edge Innovations in Sustainable Building Materials

-

Bio-Based Materials and Bioplastics

The innovation with the greatest potential lies with bio-based materials processed from renewable biological sources such as algae, fungi, and agricultural waste. In this new material group, including a wide range of substitute materials for traditional plastics, synthetics, and even concrete, there is less embodied energy and better biodegradability.

For instance, mycelium (the root structure of fungi) has been developed into strong, lightweight, insulating, packaging, or even structural (and renewable!) panels. In some uses, mycelium panels may sequester carbon during growth (thus making them carbon-negative).

Similarly, algae-based bioplastics are developing as a renewable option for ‘interior finishes’, facade elements or as decorative objects. Algal bioplastics can be manufactured quickly and use little land and water. Their biodegradable end-of-life properties guarantee low impact on the environment.

-

Recycled and Circular Materials

A circular economy is at the core of sustainable construction, and exciting progress is evident in this area. Recent developments in recycling technology now enable waste materials, such as plastics, glass and metals, to be recycled on a scale that had previously only been imagined.

Some of the latest approaches involve recycling construction and demolition waste and recovering high-performance composites and aggregates. For example, waste glass is being turned into high-performance, tough glass fibre-reinforced concrete with minimum volume of virgin raw materials. Plastics can equally be recycled into durable insulation panels or composite decking.

The advent of modular manufacturing methods also enhances the circularity of building materials by rendering components demountable and reusable. Digital tracking and certification systems ensure material provenance and lifecycle management with sustainable procurement and deconstruction practices.

-

High-Performance Insulation Materials

Continuous improvements in energy efficiency remain a pillar of sustainable building. The realized advancements in high-performance insulation material are a major milestone. Aerogels and vacuum-insulated panels (VIPs) now provide high thermal resistance in a thin form, virtually eliminating the energy needed for heating and cooling.

Further developments are coming in the form of bio-based aerogels made from cellulose or lignin, renowned for their high insulation value, that are biodegradable. These materials are light-weight, flame-resistant, and can be installed seamlessly in walls, roofs, and windows.

In addition, phase-change materials (PCMs) are being implemented in a building’s envelope to provide dynamic control of indoor spaces, reducing mechanical inputs for heating and cooling. All these innovations cumulatively contribute to extreme energy conservation and carbon dioxide reduction.

-

Carbon-Storing Concrete and Cements

Concrete, historically a major contributor to embodied carbon, is undergoing transformative changes. Researchers have come up with other mixes like geopolymer concrete, which minimizes or does away with the use of Portland cement, which greatly reduces carbon emissions.

Recent innovations also involve carbon-capturing concrete that uptakes CO₂ in the curing process or throughout its service life. These materials sequester carbon actively, making concrete a carbon sink from previously being a carbon source. Such technological advancements could radically reduce the construction industry’s overall carbon emissions.

-

Smart and Adaptive Materials

The integration of smart technology and sensors into building materials is creating new opportunities for more sustainable building design. Self-healing concrete, for instance, has microcapsules that release healing agents when cracks develop, lengthening the lifespan of buildings and cutting maintenance requirements.

Thermochromic and photochromic materials alter color or properties in accordance with environmental stimuli, adjusting light absorption and thermal management automatically. The adaptive materials ensure energy efficiency, occupant comfort, and overall sustainability.

-

Mycelium Materials

The shift toward sustainable building materials has driven the exploration of the possibility of using biological organisms, especially plants and fungi, as safe, environmentally friendly substitutes for conventional building materials. Of these, the mycelium—the fungal root structure—is a paradigm-changing material that represents the values of sustainability, resilience, and adaptability.

Mycelium naturally grows by breaking down organic material, so it is a renewable resource that can be grown rapidly and with minimal environmental footprint. When harvested, it can be formed into high-density, low-weight panels appropriate for insulation, bricks, or even load-bearing applications. These materials are not only biodegradable but also have exceptional thermal and acoustic insulating characteristics, positioning them as optimal choices for eco-friendly building.

Additionally, the fact that mycelium can be grown in molded form allows it to be produced in sophisticated, tailored shapes without requiring huge amounts of machining or processing. The biofabrication process minimizes waste and energy use immensely. Moreover, mycelium composites can absorb carbon while they develop, making them carbon-negative materials—a critical characteristic for addressing climate change.

In addition to mycelium, other plant-derived materials like bamboo, hempcrete (concrete made from hemp), and straw bale have gained traction. These bio-derived materials use fast-growing, renewable plant crops that incorporate CO₂ during their growth, thus reducing the overall carbon footprint of building projects. Examples include bamboo’s great strength-to-weight ratio used for structural and architectural components as a renewable alternative to timber that can be harvested every few years with little adverse impact on the ecosystem.

-

Metamaterials

Metamaterials, a type of engineered material, can be designed to exhibit properties that otherwise occur naturally. They can become some of the more innovative technologies available for sustainable construction. Initially researched within physics for their extraordinary electromagnetic characteristics, metamaterials are today being repurposed to solve key problems in building construction ranging from insulation and soundproofing to resilience and environmental responsiveness.

In construction, metamaterials are produced through structuring conventional materials at micro- or nano-levels to manage physical phenomena like heat transfer, vibration, and light in new ways. Their precision ability to manipulate these phenomena allows for unheard of levels of energy savings, strength, and environmental tolerance.

One of the most important applications of metamaterials is thermal insulation. By designing materials that are capable of selectively absorbing or reflecting infrared radiation, engineers are able to create insulation panels highly effective at downgrading heat loss. These metamaterials can be designed to dynamically adjust to varying conditions of temperature, resulting in buildings that are far more energy efficient and that are able to create optimally conditioned indoor climates with very little energy input.

Another use exists in acoustic metamaterials, which have the ability to control sound waves to produce extremely efficient noise barriers or interior soundproofing. By designing microstructures in a bespoke manner, such materials can prevent certain frequencies, thereby enabling quieter, more hospitable indoor spaces alongside minimized energy expenditures for HVAC or air purification equipment.

Challenges and Future Outlook

Despite promising breakthroughs, several challenges hinder the widespread adoption of new materials. These are high cost development, regulatory barriers, product certification needs, and industry-wide acceptability needs. Additionally, the long-term performance as well as durability information for most innovative materials is still being assessed, which affects confidence between developers and regulators.

However, the future outlook is optimistic. Governments and industry bodies are giving more importance to sustainable building, which has resulted in favorable policies and incentives. Market estimations predict a strong growth path for sophisticated sustainable materials based on climate pledges, corporate social responsibility, and technological innovation.

In addition, scientists, manufacturers, architects, and policymakers must join hands to spur innovation, standardization, and scaling up of these materials. Awareness and education are also necessary to eliminate myths and foster the advantages of green building solutions.

Conclusion

The innovations in green building materials are a quantum leap to sustainable, environmentally friendly construction practice. From recycled and bio-based materials to intelligent and adaptive technologies, innovation is transforming the potential for creating resilient, efficient, and low-impact infrastructure.

There are still challenges, but sustainable building materials backed by technology and co-operation offers a future in construction not just for reducing environmental footprint, but actively restoring the environment. As the industry embraces these innovations, the road to an environmentally responsible built environment is becoming clearer and finally guaranteeing that new buildings serve the benefit of humankind and the planet in harmony.