Tight project timelines, rising material costs and supply chain uncertainty have made speed a critical differentiator in today’s construction and industrial sectors.

Examine leading providers capable of delivering accelerated powder coating services to help project managers and contractors keep operations moving when time is limited.

Are There Any Powder Coaters That Specialize in Rush Orders?

The following companies have established reputations for managing accelerated timelines in industrial and construction contexts. Each entry highlights operational strengths, rush order capabilities and the types of projects they handle.

The information combines verified service details, lead-time guarantees and industry feedback to help professionals quickly identify the right partner for rush-order powder coating.

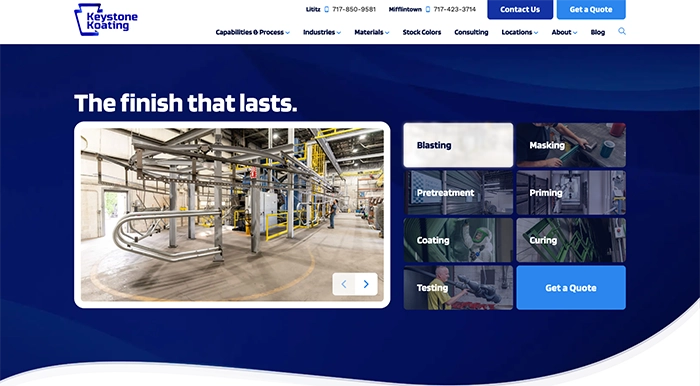

1. Keystone Koating — Fast Turnaround and Industrial Expertise

Keystone Koating delivers industrial‑grade powder coating services with a strong reputation for handling urgent timelines and high‑demand production runs, making it a top choice among powder coaters that specialize in rush orders. With advanced batch ovens, custom pretreatment bays and large capacity booths, the company is equipped to coat significant volumes and oversized components that many competitors cannot accommodate.

What sets Keystone Koating apart is its structured workflow designed for speed and precision, enabling expedited lead times without sacrificing finish integrity. Its processes support architectural, manufacturing and commercial coatings, including anti‑corrosion and high‑durability finishes tailored to construction specifications.

Contractors and project managers can expect clear communication on turnaround expectations and logistical support for pick‑up and delivery, which helps keep critical deadlines on track. By combining industrial capacity with responsive service, Keystone Koating is positioned as a reliable partner when powder coating needs intersect with urgent project milestones.

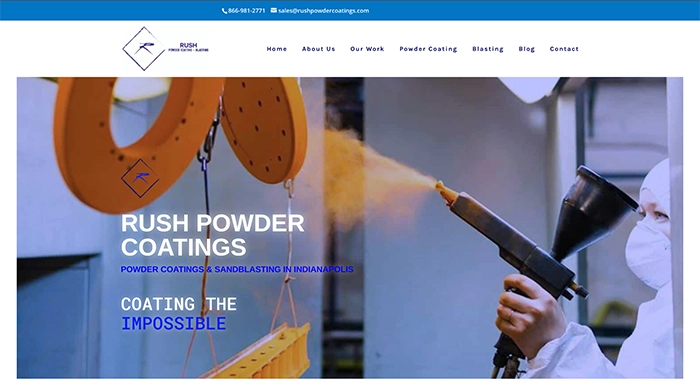

2. Rush Powder Coatings — Dedicated to Rapid Industrial Jobs

Rush Powder Coatings in Indianapolis is specifically designed for expedited service to industrial and manufacturing clients. The company boasts ovens and powder booths sized for both large and small batches. It regularly supports accelerated turnaround goals, sometimes as fast as 48 hours when required.

Rush focuses on coating heavy equipment, complex assemblies and commercial components that typical shops may delay due to size and workflow constraints. With pickup and delivery options and a heritage rooted in solving rush-order challenges, it is a practical choice for contractors needing powder coaters who can rush orders without compromising protective quality.

3. Prism Powder Coatings Ltd. — ISO‑Certified Supply With Fast Delivery

Prism Powder Coatings Ltd. is an ISO‑certified manufacturer and supplier of powder coating finishes with a history of rapid processing for custom and standard coatings. While its primary business is manufacturing coating materials, it is known in industry circles for offering quick turnaround on orders of powders and specialty finishes, including low-bake and fast-cure systems that support accelerated production schedules.

This focus on efficient supply logistics can help fabricators and coaters shorten lead times by securing materials ahead of rush projects, a crucial step for planners and procurement specialists working with tight timelines.

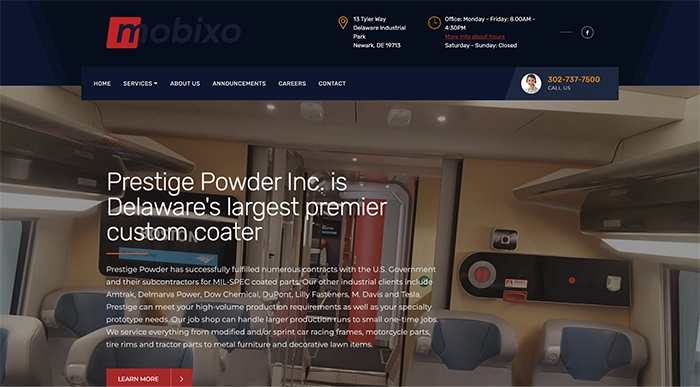

4. Prestige Powder, Inc. — Mid‑Atlantic Custom Coating With Reliable Timelines

Prestige Powder, Inc. is Delaware’s largest custom coater, serving industrial, manufacturing and specialist markets across the Mid‑Atlantic region with a broad portfolio of powder coating and media blasting services.

Renowned for meeting promised delivery dates and handling both high‑volume production and one‑off jobs, Prestige has established a reputation for dependable service in projects where deadlines matter. Its capacity for oversized parts and detailed masking ensures that complex construction components and industrial assemblies are finished to specification on time.

By coordinating workflows and maintaining strategic production planning, Prestige consistently delivers results that align with customer scheduling requirements, making it a strong candidate when assessing powder coaters that specialize in rush orders.

5. Diamond Metal Finishing — Industrial‑Grade Finish With Efficient Processing

Diamond Metal Finishing delivers powder coating services designed for industrial durability and performance, supporting small prototypes through large production volumes with streamlined operations that emphasize efficient processing.

Though not exclusively a “rush only” coater, its advanced facilities promote quick turnaround times across a range of coating projects, from architectural panels to complex structural parts, by leveraging streamlined workflows and in‑house color matching and surface preparation.

For construction and manufacturing professionals seeking reliable finish quality within tight project windows, Diamond Metal Finishing combines precision craftsmanship with the operational depth to support accelerated schedules when necessary.

Key Features at a Glance

To help professionals quickly evaluate providers, the table below summarizes critical features of each coater, including turnaround speed, capacity, certifications and industry specialties. This comparison highlights which vendors are best suited for urgent projects, large-scale orders or specialized industrial applications.

| Company | Typical Rush Turnaround | Max Part Size | High-Volume Capacity | Certifications and Compliance | Primary Industries Served |

| Keystone Koating | 24 to 72 hours | Up to 20 ft | High | ISO 9001-aligned QA processes | Construction, industrial and commercial manufacturing |

| Rush Powder Coatings | 24 to 48 hours | Up to 15 ft | Medium to high | Industry-standard QC protocols | Manufacturing and industrial equipment |

| Prism Powder Coatings Ltd. | 48 to 72 hours | Up to 12 ft | Medium | ISO 9001 Certified | Manufacturing, automotive and industrial |

| Prestige Powder, Inc. | Three to five days | Up to 18 ft | High | Industry-standard compliance systems | Construction, industrial and infrastructure |

| Diamond Metal Finishing | Three to four days | Up to 14 ft | Medium to high | Industry-standard QC and safety programs | Industrial, architectural and manufacturing |

How These Powder Coaters Were Selected

The highlighted companies consistently meet urgent coating needs without sacrificing quality. Providers were evaluated based on turnaround speed, capacity for both small and large-scale projects and ability to maintain quality under compressed schedules. Other criteria included certifications, compliance with industry standards and geographic coverage to support regional and national projects.

Customer feedback and project case studies also informed the selection, ensuring recommendations reflect real-world reliability. By focusing on these metrics, this list identifies powder coaters that rush orders effectively while maintaining rigorous operational standards, giving construction and industrial professionals a trusted reference for high-pressure scenarios.

Why Rush Powder Coating Matters in Construction and Industrial Projects

In fast-paced construction and industrial environments, time is money. Delays in finishing metal components can stall entire projects, impacting budgets and client satisfaction. A 2025 Sherwin-Williams industry survey of construction professionals working on high-value projects found that 87% experienced costly project delays due to material shortages. Standard coating timelines are often incompatible with urgent project schedules, making access to powder coaters that specialize in rush orders a strategic advantage.

These providers can deliver high-quality finishes within compressed windows, minimizing downtime and keeping supply chains on track. For contractors, fabricators and industrial planners, prioritizing vendors capable of expedited service ensures that critical deadlines are met without compromising durability or compliance. Rush coating is particularly valuable for emergency repairs, last-minute client demands and seasonal production peaks.

Key Features to Look for in Powder Coaters That Specialize in Rush Orders

Not all powder coaters are equipped to handle tight deadlines, so understanding key service attributes is critical. Professionals should consider the following:

- Guaranteed turnaround times: Clear commitments, often 24 to 72 hours, ensure predictability.

- Dedicated rush production lines: Facilities with specialized workflows reduce bottlenecks.

- High-volume capabilities: Ability to handle large batches without compromising finish quality.

- Logistics support: Coordination of pickup, delivery and storage saves time and reduces errors.

- Quality assurance protocols: Even under time pressure, inspections, certifications and finish standards remain intact.

Evaluating providers against these factors ensures that urgent projects can proceed without sacrificing the durability and appearance of coated components.

Fast Coating, Faster Deadlines

In industries where every day counts, partnering with powder coaters that specialize in rush orders can mean the difference between project delays and on-time delivery. Vendors like Keystone Koating combine speed, precision and logistical expertise to keep construction and industrial projects moving.

By carefully matching vendor capabilities to project requirements, professionals can maintain both efficiency and quality, proving that with the right partner, even the tightest deadlines won’t leave your schedule rusting behind.