Cutting Carbon, Building Concrete: Innovations in Low-Carbon Mixes

The construction industry stands at a pivotal moment where environmental responsibility meets structural necessity. As concrete production accounts for approximately 8% of global CO2 emissions, the development of low-carbon concrete mixes has emerged as one of the most critical innovations in sustainable construction. These revolutionary formulations are transforming how builders approach projects, offering substantial carbon reductions while maintaining the structural integrity that modern construction demands.

The Carbon Challenge in Traditional Concrete

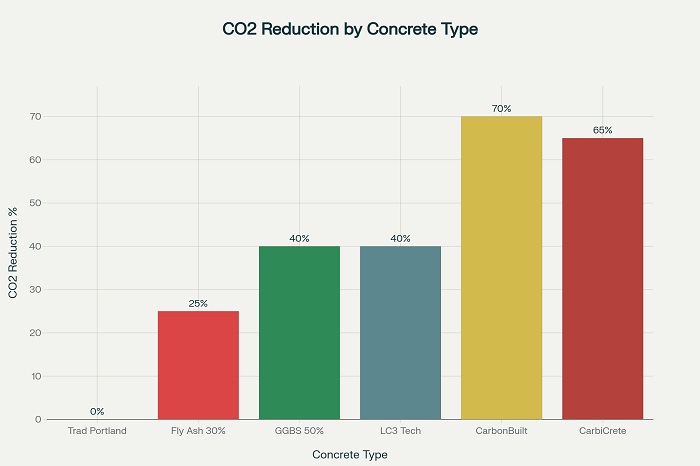

Traditional Portland cement concrete carries an enormous environmental burden. The production of ordinary Portland cement requires heating limestone to extreme temperatures of over 2,300 degrees Fahrenheit, consuming vast amounts of fossil fuels and releasing significant quantities of carbon dioxide through both the energy-intensive process and the chemical breakdown of limestone itself. This double impact makes cement manufacturing one of the most carbon-intensive industrial processes worldwide.

The urgency for alternatives has intensified as global construction demands continue to rise. Experts estimate that the world will need to build two billion new homes by 2100 to accommodate population growth. Meeting this demand with traditional concrete would exacerbate climate change significantly, making the transition to low-carbon concrete mixes not just beneficial but essential for planetary sustainability.

Revolutionary Material Substitutions

Supplementary Cementitious Materials (SCMs)

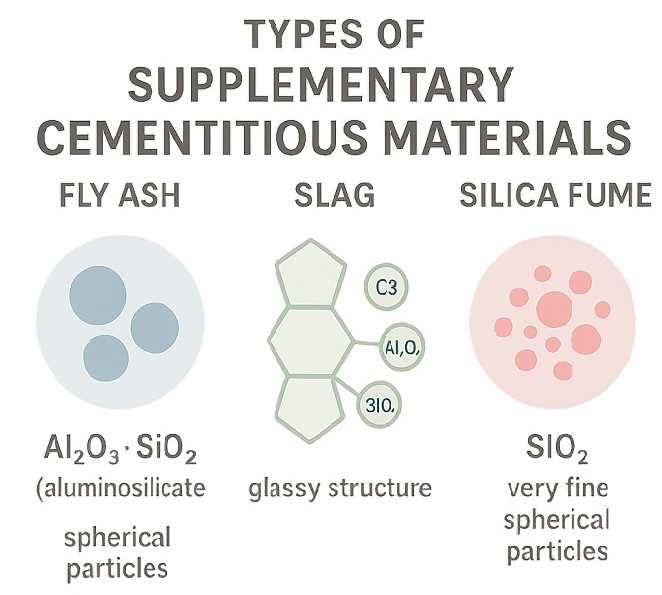

The foundation of low-carbon concrete mixes lies in supplementary cementitious materials that can replace significant portions of Portland cement. These materials, often industrial byproducts, provide comparable binding properties while drastically reducing embodied carbon.

Fly ash, a byproduct of coal combustion, represents one of the most established SCMs in low-carbon concrete mixes. When incorporated at replacement levels of 20-40% of cement content, fly ash not only reduces carbon emissions but also enhances workability and long-term strength development. The pozzolanic reaction between fly ash and calcium hydroxide creates additional binding compounds, often resulting in concrete that surpasses traditional mixes in durability.

Ground granulated blast furnace slag (GGBS), derived from steel production, offers even more dramatic carbon reductions. Projects have successfully utilized GGBS replacement levels of up to 70% of cement content, achieving carbon footprint reductions of 30-70% compared to conventional concrete. The latent hydraulic properties of GGBS contribute to enhanced chemical resistance and reduced permeability, making these mixes particularly suitable for infrastructure applications exposed to harsh environments.

Advanced Cement Alternatives

Recent innovations in cement chemistry are producing entirely new binding systems. Limestone calcined clay cement (LC3) technology, developed through international collaboration, can reduce concrete emissions by up to 40% while maintaining performance standards. This technology utilizes calcined clay as a supplementary material, creating a reaction that enhances strength development and durability.

Revolutionary companies are pushing boundaries even further. CarbonBuilt’s proprietary binder system actually captures and stores CO2 during the curing process, displacing carbon-intensive cement to reduce concrete’s carbon footprint by up to 70%. Similarly, CarbiCrete’s approach completely eliminates cement by replacing it with steel industry byproducts and utilizing carbon mineralization to remove atmospheric CO2 that becomes permanently stored within the concrete matrix.

Artificial Intelligence Optimizing Mix Design

The complexity of optimizing concrete mixes for multiple attributes including strength, curing time, and sustainability has led to groundbreaking applications of artificial intelligence. Meta’s collaboration with the University of Illinois has produced an AI model that can predict strength curves while simultaneously optimizing for environmental impact and construction feasibility.

This AI-driven approach uses Bayesian optimization to generate hundreds of systematic data points through iterative laboratory testing. The model can incorporate novel materials into mix predictions, helping researchers understand the viability of emerging low-carbon alternatives. In laboratory testing, the AI has demonstrated the ability to reduce emissions by up to 70% without compromising structural requirements.

The open-source nature of these AI tools is accelerating adoption across the industry. By making optimization algorithms freely available, the technology enables concrete producers worldwide to develop locally optimized low-carbon concrete mixes that utilize available materials while meeting specific performance criteria.

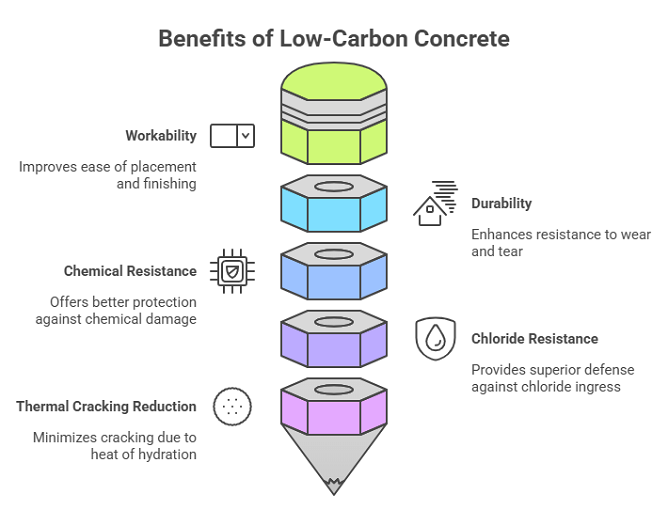

Performance Advantages Beyond Carbon Reduction

Low-carbon concrete mixes often deliver performance benefits that extend well beyond environmental considerations. The incorporation of SCMs typically improves workability, making concrete easier to place and finish. The refined pore structure that develops from pozzolanic reactions enhances durability and chemical resistance, often extending service life beyond that of conventional concrete.

Many low-carbon formulations demonstrate superior resistance to chloride ingress, making them particularly valuable for marine environments and structures exposed to de-icing salts. The reduced heat of hydration in many low-carbon mixes minimizes thermal cracking in mass concrete applications, improving long-term structural integrity.

Overcoming Implementation Challenges

Despite their advantages, low-carbon concrete mixes face several implementation challenges that the industry continues to address. Supply chain constraints represent a significant hurdle, as the availability of quality SCMs varies by region and can be limited by the output of source industries.

Extended curing times in some low-carbon formulations have required innovative approaches to maintain construction schedules. Advanced admixture systems are now available that can accelerate early strength development in low-carbon mixes, enabling standard construction timelines while preserving environmental benefits.

Quality control procedures have evolved to accommodate the unique characteristics of low-carbon concrete mixes. Enhanced testing protocols ensure that these formulations meet specification requirements while providing contractors and engineers with confidence in their performance.

Economic Considerations and Market Adoption

The economic landscape for low-carbon concrete mixes continues to improve as carbon pricing mechanisms and environmental regulations increase the cost of high-carbon alternatives. Many projects now demonstrate cost neutrality or even savings when considering the total lifecycle costs of low-carbon concrete mixes, including reduced environmental compliance costs and enhanced durability.

Government initiatives are accelerating adoption through procurement requirements and incentive programs. The Biden-Harris administration’s Concrete Innovation Summit has highlighted federal commitment to commercializing clean concrete technologies, while similar initiatives worldwide are creating market demand for low-carbon alternatives.

Industry Transformation and Future Outlook

Major concrete producers are rapidly scaling production of low-carbon concrete mixes to meet growing demand. Partnerships between technology companies, cement manufacturers, and construction firms are creating integrated supply chains that make these advanced materials increasingly accessible to mainstream construction projects.

The integration of digital tools including Building Information Modeling (BIM) with low-carbon material specifications is streamlining the design process, enabling architects and engineers to optimize both structural performance and environmental impact from the earliest design phases.

Research continues into next-generation technologies including geopolymer concrete systems that can eliminate Portland cement entirely while utilizing industrial waste streams. These emerging technologies promise even greater carbon reductions while expanding the range of suitable applications.

The transformation toward low-carbon concrete mixes represents more than environmental compliance; it embodies a fundamental shift toward regenerative construction practices. As these technologies mature and scale, they offer the construction industry a pathway to meet growing infrastructure needs while actively contributing to climate stability.

Through continued innovation in materials science, artificial intelligence optimization, and integrated supply chain development, low-carbon concrete mixes are positioned to become the standard rather than the alternative in sustainable construction. This evolution ensures that the built environment can serve human needs while preserving planetary health for future generations.