JCB Powertrain is set to unveil its latest drivetrain innovation at Conexpo in Las Vegas, where it will introduce the JCB DualTech VT transmission to third-party OEM customers for the first time. The technology is designed to improve productivity and efficiency in applications that require both precise low-speed control and efficient higher-speed travel.

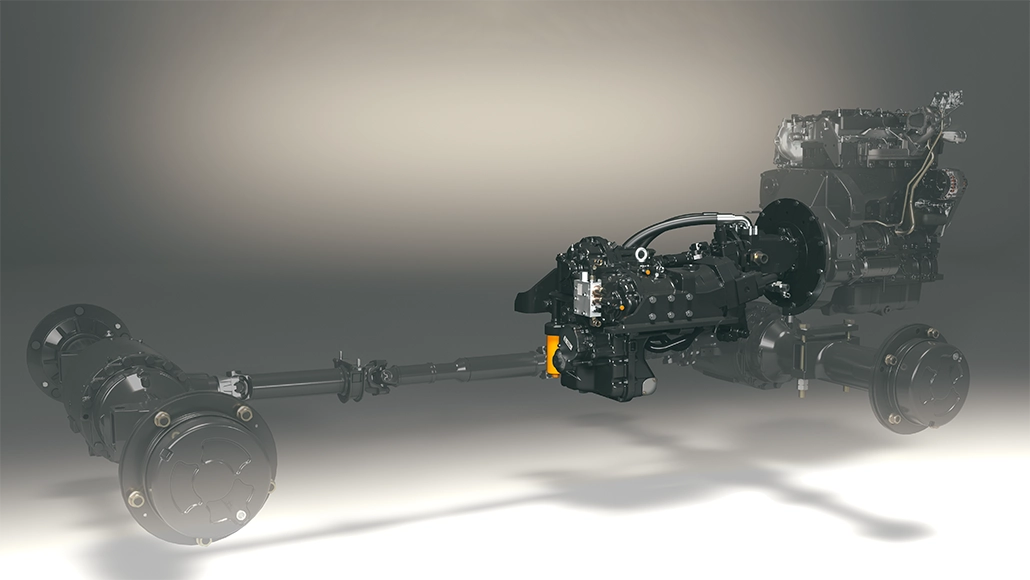

The new derivative of the JCB DualTech VT transmission builds on the technology first launched in JCB machines in 2016. It has been re-engineered into a compact inline layout, making it suitable for wheeled machines with conventional drivetrain architectures and a wide range of OEM applications.

JCB Powertrain global sales and applications manager Jon McNulty said, “If you have a product or application that requires a mix of low-speed duties mixed with higher-speed/roading requirements, then DualTech VT is the perfect fit – in other words, it’s the best of both worlds.”

He added: “It’s an all-new design and package, tailored initially for the recently launched JCB TM280 loading shovel model. However, due to its compact design, this new derivative of DualTech VT could be integrated to several OEM applications and deliver a ‘best of both worlds’ combination of low-speed hydrostatic controllability combined with a seamless handover to direct mechanical drive, maximising efficiency in the higher speed range.”

DualTech VT combines hydrostatic drive and direct mechanical transmission within a single unit. It delivers hydrostatic performance up to 25 km/h for controlled loading, handling and yard work, before transitioning seamlessly to mechanical drive for efficient travel speeds of up to 40 km/h.

Alongside DualTech VT, JCB Powertrain will also unveil the new SS670 Synchro-Shuttle transmission. The SS670 replaces the SS600, SS700 and SS750 models and is designed as a cost-effective, high-volume solution for off-highway machines such as site dumpers, backhoe loaders and rough-terrain forklifts.

The SS670 incorporates the W300 torque converter and latest synchroniser technology to improve shift quality while reducing churning losses and enhancing overall efficiency. JCB said the transmission draws on 48 years of in-house design, development and manufacturing expertise at its Wrexham facilities in North Wales.

Also on display will be JCB’s hydrogen combustion engine programme. The company said more than 150 evaluation engines have already been produced and real-world pre-launch testing is at an advanced stage across multiple machine platforms.