The first thing to realise with water filtration systems is that they need to be built to cater to specific demands. Good design begins with a lab report, not browsing a random catalogue. That being said, what does the process look like, from start to finish? Let’s take a closer look.

Water sample testing

First of all, a composite sample should be taken from the borehole and sent to a UKAS-accredited lab to profile microbiology, metals (like iron, manganese), hardness, pH, turbidity, ammonia and any other problematic impurities (hydrogen sulphide, colour).

The results will determine which treatment is best. In particular, whether you need to pursue oxidation for dissolved metals, pH correction, or other specialist approaches.

In the UK, certain water supplies also need to meet the Private Water Supplies Regulations, so the test also ensures that you’re able to remain compliant. If uncertain on these regulations, ask your borehole provider (such as Teckna Group) to advise.

Define the scope of the water system needs

Next, you’ll need to make sure that the system is able to deal with peak flow and daily demand, then choose how water will move: direct from the pump through treatment, or via a break tank, with a booster set to decouple variable borehole yields from household water requirements or site peaks.

For business-critical boreholes, having standby UV filters or even twin filters can help to ensure uptime during maintenance or when dealing with other issues.

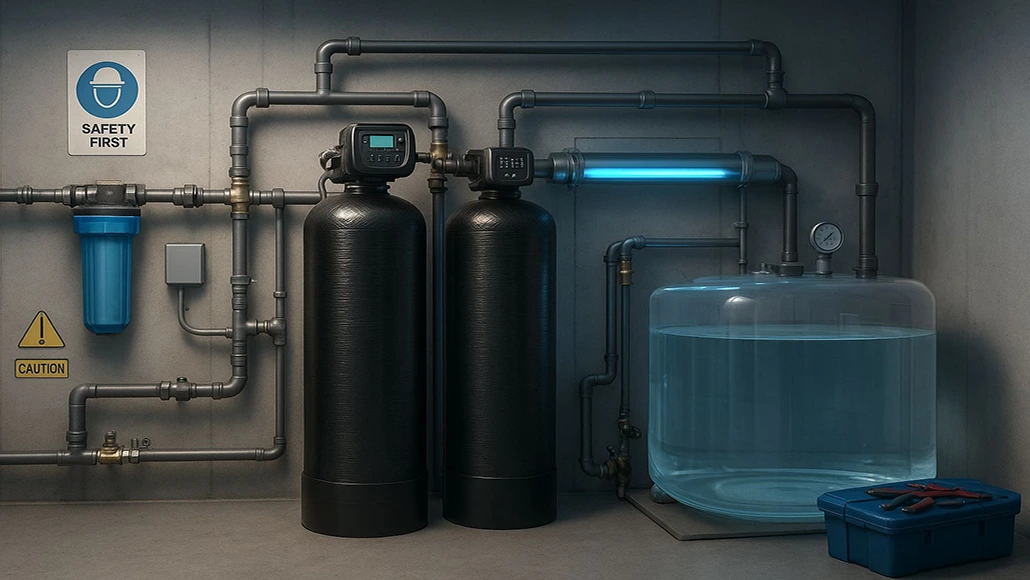

Build the treatment train

Every treatment train will need to be custom-designed, but in a lot of situations, it will look something like this:

- Sediment pre-filtration to catch sand/silt and protect downstream media.

- Iron/manganese removal media (e.g., catalytic manganese dioxide/“greensand-type” media) with automatic backwash.

- You may need to ensure pH correction (calcite/dolomite) if the water is corrosive, to protect plumbing and ensure that downstream processes work properly.

- Softening or specific ion exchange if hardness scaling, nitrate or ammonia requires targeted removal.

- UV disinfection is the final stage of the process, for microbes, installed after turbidity-forming contaminants are controlled so UV light can reach all of its targets.

It’s important that these systems are all designed to work in tandem, to deal with specific issues that are present in the water supply.

Maintaining the system

You’ll want to set a service schedule early on, to make sure that the system remains fully functional. Include UV lamp and sleeve changes, media backwash and top-ups, pre-filter swaps, tank cleans, and periodic resampling of both pre- and post-filtration water sources.

Many installers recommend UV as a standing control with pre-filters and, where test results suggest, add-ons like iron/manganese. It’s imperative that you keep the system running properly, especially if the water is consumed by people or livestock – it’s not just a regulatory hurdle, but can have a big impact on health and safety.

Design should be based on this general kind of sequence. Get the data first, build a treatment train that addresses your aquifer’s specific impurities, and then make sure that everything flows properly. Do that, and a borehole becomes a reliable, regulation-compliant supply – not a maintenance headache.