A team at the University of California, Berkeley, has developed a type of concrete that uses a lacy polymer lattice that allows it to bend without cracking and at the same time reduce its carbon emissions.

A paper published in the journal Materials & Design describes how printed plastic lattices can be filled with ultra-high performance concrete.

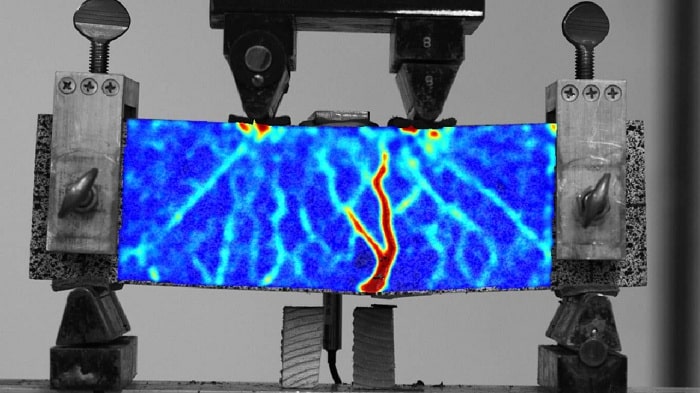

According to the team’s research, the finished material performs four times better than conventional concrete in compression and bending tests.

Claudia Ostertag, a professor of civil and environmental engineering who co-authored the paper, said: “When a material is brittle, it can hold up to a certain peak load and then it fails. In this case, we did not observe that failure. It got stronger and stronger. For those of us interested in concrete, this is amazing. You are rendering something very brittle into something very ductile.

She added: “Cracks are very clever: they will choose the path of least resistance. However, in this case the cracks are no longer able to avoid the reinforcement due to its uniform 3D arrangement.”

In future, researchers will test to see how different designs of lattices work with different forms of concrete and in particular applications.