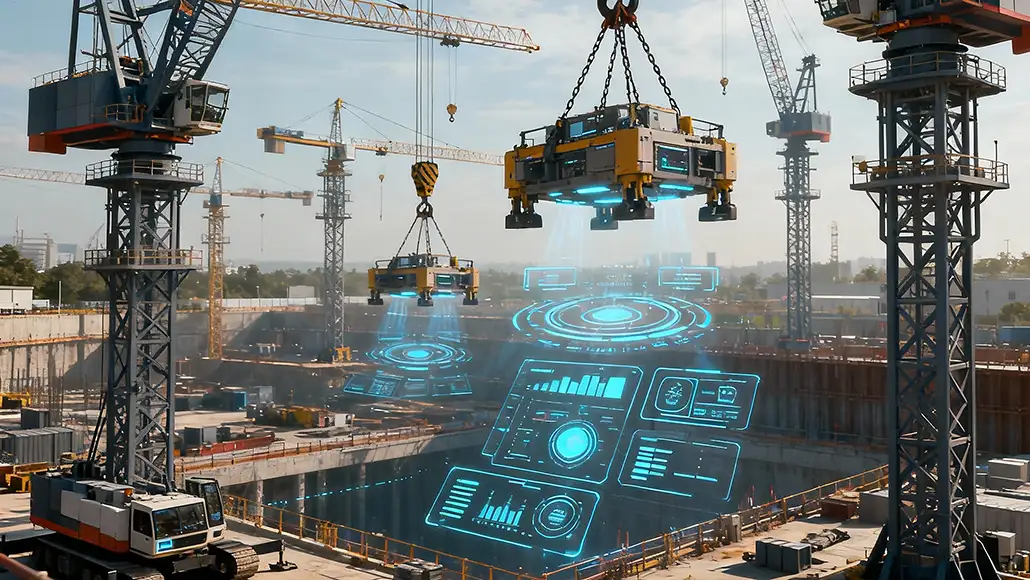

The construction sector experiences fundamental transformation as digitalization lifting operations construction reshapes how projects approach material handling, equipment deployment, and operational management. This evolution extends beyond simple technology adoption to encompass comprehensive reimagining of workflows, decision-making processes, and organizational capabilities. Digital systems now provide real-time insights, enable predictive analytics, and facilitate coordination that elevates lifting operations from manual processes to data-driven, intelligent activities.

The Digital Transformation Imperative

Construction lifting operations have historically relied on paper-based planning, experience-driven decision-making, and limited visibility into equipment performance. While this traditional approach served the industry adequately when projects proceeded at measured paces with ample contingency time, modern construction demands—compressed schedules, tighter budgets, and heightened safety expectations—require more sophisticated approaches. Digitalization lifting operations construction addresses these demands by providing tools that optimize resource utilization, prevent problems before they manifest, and enable coordination impossible through conventional methods.

The transformation encompasses multiple technology domains working synergistically. IoT sensors generate real-time operational data. Cloud computing platforms store and process this information at scale. Advanced analytics extract actionable insights from data streams. Mobile applications deliver information to decision-makers regardless of location. Building Information Modeling systems integrate lifting operations into comprehensive project digital representations. The convergence creates ecosystems where information flows seamlessly between physical operations and digital management systems.

Early adopters of digitalization lifting operations construction report substantial benefits. Equipment utilization increases as data-driven scheduling eliminates idle time and optimizes deployment across multiple work areas. Maintenance becomes predictive rather than reactive, reducing emergency repairs and extending equipment lifespan. Safety improves through continuous monitoring that identifies hazards before incidents occur. Project timelines shorten as coordination inefficiencies diminish and problems receive earlier intervention.

Connected Equipment and IoT Integration

The foundation of digitalization lifting operations construction rests on connected equipment that continuously communicates status, performance metrics, and operational parameters. Modern cranes, hoists, and lifting accessories incorporate sensors and communication modules that transform them from passive tools into intelligent systems capable of self-monitoring and information sharing. This connectivity enables unprecedented visibility into equipment condition, utilization patterns, and operational efficiency.

Load monitoring systems exemplify this connectivity. Rather than relying on operator estimation or periodic verification, digital systems continuously measure load weights and compare them against rated capacities. This real-time monitoring prevents overloading that risks equipment failure or structural collapse. Historical load data reveals utilization patterns that inform equipment selection for future projects and support capacity planning during current operations.

Positioning systems track crane locations, boom angles, and hook coordinates with precision measured in centimeters. This spatial awareness enables automated collision avoidance, supports lift path optimization, and facilitates coordination when multiple cranes operate in proximity. Integration with project models allows comparison between planned and actual positions, identifying deviations that might indicate problems requiring attention.

Environmental sensors measure wind speed, temperature, and other conditions affecting safe operation. Digital systems process this data continuously, alerting operators when parameters approach limits and automatically restricting operations if thresholds are exceeded. This environmental monitoring proves particularly valuable for tall tower cranes where ground-level conditions differ substantially from heights where operations occur.

Operational cycle tracking captures detailed information about every lift—duration, path traveled, load characteristics, and any anomalies encountered. Aggregated over time, this data reveals productivity patterns, identifies bottlenecks, and supports continuous improvement initiatives. Project managers access dashboards displaying real-time and historical metrics that inform decisions about resource allocation and schedule optimization.

Data Analytics and Performance Optimization

The data streams generated by connected equipment enable sophisticated analytics that drive operational optimization. Digital platforms employ algorithms ranging from basic statistical analysis to advanced machine learning that identifies patterns and relationships human analysis might miss. These analytical capabilities transform raw data into actionable intelligence that improves decision-making across organizational levels.

Predictive analytics forecast equipment maintenance needs based on operational history, usage intensity, and environmental exposure. Rather than following fixed maintenance schedules that may intervene too early or dangerously late, predictive approaches schedule maintenance precisely when condition assessment indicates necessity. This optimization reduces maintenance costs while improving equipment reliability and safety margins.

Performance benchmarking compares current operations against historical baselines, industry standards, or theoretical optimal performance. Digitalization lifting operations construction enables identification of underperforming equipment, operators requiring additional training, or processes warranting refinement. The objective data supporting these assessments depersonalizes improvement discussions and focuses attention on systemic factors rather than individual blame.

Resource allocation optimization uses historical project data and real-time progress information to recommend equipment deployment strategies. When multiple lifts require completion and several cranes remain available, digital systems can evaluate various assignment scenarios and suggest approaches that minimize total completion time or maximize overall efficiency. This computational capability exceeds human planning capacity, particularly as project complexity increases.

Energy consumption monitoring tracks power usage patterns and identifies opportunities for reduction. Digital systems might recognize that certain operational sequences or equipment configurations consume excessive energy, suggesting alternatives that deliver equivalent results with lower consumption. The cumulative effect of numerous small optimizations substantially reduces operational costs while supporting sustainability objectives.

Digital Twin Technology for Lifting Operations

Digital twin applications represent advanced implementations of digitalization lifting operations construction principles. These virtual replicas of physical equipment or complete lifting systems enable simulation, testing, and optimization in digital environments before physical execution. The technology proves valuable for planning complex lifts, training operators, and predicting equipment behavior under various scenarios.

For crane operations, digital twins combine precise 3D models of equipment with real-time sensor data from physical counterparts. This integration creates virtual representations that mirror actual crane conditions, positions, and capabilities. Project teams can test lifting plans against digital twins, identifying potential problems such as reach limitations, stability concerns, or collision risks before mobilizing equipment. This virtual validation reduces planning time, prevents costly field modifications, and improves confidence in execution approaches.

Digital twins support operator training by providing realistic simulation environments where trainees practice procedures without risking equipment damage or safety incidents. The virtual environment responds to control inputs with physics-based behavior that accurately represents actual equipment, building operator proficiency before physical operation begins. This training approach proves particularly valuable for complex or infrequently performed operations where physical practice opportunities remain limited.

Predictive capabilities of digital twins extend to structural health monitoring. By comparing sensor data from physical equipment against digital twin models, systems identify deviations indicating developing problems. Unusual stress patterns, degraded performance, or component wear reveal themselves through discrepancies between expected and actual behavior, triggering maintenance interventions before failures occur.

Integration with Building Information Modeling

The convergence of digitalization lifting operations construction with BIM creates powerful synergies that enhance planning precision and execution efficiency. BIM provides comprehensive three-dimensional representations of construction projects including spatial relationships, schedules, and component attributes. When lifting operations integrate with these models, planners can visualize equipment positioning, verify clearances, and coordinate activities with unprecedented accuracy.

Crane placement planning benefits substantially from BIM integration. Rather than relying on two-dimensional drawings and manual calculations, planners position virtual cranes within BIM environments and verify that reach, capacity, and clearance requirements meet project needs. The software automatically checks for conflicts with existing structures, utilities, or planned construction elements, identifying problems that traditional planning might overlook until field mobilization reveals them.

Lift path planning within BIM environments enables verification that planned movements avoid obstacles and maintain safe clearances throughout operations. The three-dimensional visualization reveals potential problems—such as boom conflicts with structural elements or load proximity to power lines—that might escape notice during two-dimensional planning. This enhanced planning reduces field surprises and improves operational safety.

Schedule integration connects lifting operations with broader project timelines, enabling coordination that prevents resource conflicts and optimizes workflow. When BIM systems incorporate fourth-dimension scheduling information, planners can verify that crane availability aligns with material delivery, identify opportunities for multi-lift sequences that improve efficiency, and coordinate with adjacent trades whose work might conflict with lifting operations.

Real-Time Collaboration and Communication

Digitalization lifting operations construction facilitates communication and collaboration that overcome traditional limitations of construction site coordination. Cloud-based platforms enable stakeholders—project managers, crane operators, engineers, and safety personnel—to access shared information regardless of physical location. This connectivity supports informed decision-making, rapid problem resolution, and coordinated responses to developing situations.

Mobile applications deliver operational information to field personnel through smartphones and tablets. Operators access lift plans, load specifications, and safety checklists without referencing paper documents that become damaged, lost, or outdated. Changes propagate instantly to all users, ensuring everyone works from current information and preventing errors resulting from outdated documentation.

Visual collaboration tools enable remote participation in complex operations. Experts located off-site can view live video feeds from job sites, observe operations in progress, and provide real-time guidance when unusual situations arise. This capability proves particularly valuable when specialized lifts require expertise not available locally or when problems emerge requiring consultation with engineering teams or equipment manufacturers.

Alert systems notify relevant personnel when situations requiring attention develop. Equipment faults, weather deterioration, schedule delays, or safety concerns trigger automated notifications that reach appropriate stakeholders immediately. This rapid communication enables faster response and prevents minor issues from escalating into significant problems through delayed awareness.

Documentation automation captures operational records without manual data entry. Digital systems log lift details, equipment inspections, operator certifications, and safety briefings automatically, creating comprehensive records that demonstrate compliance and support incident investigation if accidents occur. This automated documentation reduces administrative burden while improving record accuracy and completeness.

Workflow Optimization and Process Digitization

Beyond equipment monitoring and planning capabilities, digitalization lifting operations construction transforms operational workflows through process digitization that eliminates manual paperwork, reduces administrative overhead, and accelerates information flow. Digital work permits replace paper forms, enabling electronic approvals that compress timeline for obtaining operational authorization. Lift plans transition from printed documents to interactive digital files that incorporate photos, videos, and links to supporting information.

Inspection processes benefit from digital checklists that guide technicians through systematic equipment examinations while capturing findings in structured formats. Photos and measurements attach directly to inspection records, providing visual documentation that supports maintenance decisions and regulatory compliance. Completed inspections immediately become available to supervisors and safety managers without physical document routing, enabling faster review and decision-making.

Incident reporting digitization ensures that safety events receive proper documentation and timely investigation. Digital forms capture incident details, witness statements, and photographic evidence immediately following events while information remains fresh. Automated notifications alert safety personnel that incidents require attention, preventing delays that compromise investigation quality. The structured data collection facilitates trend analysis that identifies systemic problems warranting broader corrective actions.

Future Evolution and Emerging Capabilities

The trajectory of digitalization lifting operations construction points toward increasingly sophisticated capabilities as supporting technologies continue advancing. Artificial intelligence applications will expand beyond current analytics to autonomous decision-making in routine situations, with human oversight reserved for unusual circumstances or strategic decisions. Machine learning systems will accumulate operational knowledge that surpasses human expertise in pattern recognition and optimization.

Augmented reality integration will overlay digital information onto physical environments, providing operators and supervisors with enhanced situational awareness. Smart glasses might display load weights, equipment status indicators, and safety warnings within operators’ fields of view, merging digital and physical information seamlessly. This fusion improves decision-making while maintaining operators’ focus on physical operations.

Blockchain technology may provide tamper-proof records of lifting operations, equipment maintenance, and operator certifications. These immutable records would support equipment valuation, liability management, and regulatory compliance through verifiable documentation that stakeholders can trust completely. The transparency enabled by blockchain could transform equipment rental markets and liability determination following incidents.

The evolution of fifth-generation cellular networks enables higher bandwidth, lower latency communication that supports more sophisticated applications. High-definition video streaming from equipment cameras, real-time digital twin synchronization, and cloud-based control systems become practical as network capabilities expand. These enhanced communication foundations will enable applications currently constrained by connectivity limitations.

As digitalization lifting operations construction matures and adoption expands across the industry, the technology will transition from competitive advantage to basic requirement, establishing digital operations management as fundamental to professional construction practice rather than innovative differentiation.