Sustainable Jobsite Practices: Waste Reduction, Reuse & Lean Operations

The construction industry is undergoing a fundamental transformation as sustainable construction jobsites become the standard rather than the exception. This evolution encompasses comprehensive approaches to waste reduction, material reuse, and lean operational methodologies that minimize environmental impact while improving project efficiency and profitability. As environmental regulations tighten and client expectations evolve, construction companies are discovering that sustainable practices deliver competitive advantages that extend far beyond compliance requirements.

The Imperative for Sustainable Construction Operations

Construction and demolition activities generate approximately 600 million tons of waste annually in the United States alone, representing one of the largest waste streams in the national economy. Traditional linear construction models that follow take-make-dispose patterns are increasingly unsustainable both economically and environmentally, driving the transition toward circular economy approaches that prioritize resource efficiency and waste minimization.

Sustainable construction jobsites address multiple challenges simultaneously: reducing environmental impact, controlling project costs, improving resource efficiency, and enhancing corporate reputation. The UK’s Construction and Demolition sector, for example, generated 63.0 million tonnes of non-hazardous waste in 2022, with only 59.4 million tonnes diverted from landfills, demonstrating both the scale of the challenge and the opportunity for improvement.

The economic benefits of sustainable practices often exceed environmental considerations, with waste reduction strategies typically delivering immediate cost savings through reduced material purchases, lower disposal fees, and improved labor productivity. Projects implementing comprehensive waste management can achieve material waste reductions of 50% or more while realizing substantial cost savings throughout construction phases.

Comprehensive Waste Reduction Strategies

Proactive Planning and Design Integration

Effective waste reduction begins during design phases, where decisions about materials, construction methods, and project sequencing establish the foundation for sustainable construction jobsites. Building Information Modeling (BIM) systems enable precise material quantification that reduces over-ordering while optimizing construction sequences to minimize waste generation.

Design for disassembly principles consider end-of-life material recovery during initial design phases, specifying connections and materials that facilitate future deconstruction and material reuse. This approach extends material lifecycles while reducing long-term environmental impact through planned obsolescence prevention.

Standardization of building components and materials reduces waste through economies of scale while facilitating prefabrication approaches that minimize on-site waste generation. Modular construction methods achieve significant waste reductions by moving fabrication to controlled factory environments where material optimization and waste management are more easily achieved.

Advanced Material Management Systems

Just-in-time delivery systems minimize on-site material storage requirements while reducing waste from damage, theft, and deterioration. These systems require precise coordination between suppliers and construction schedules but deliver substantial benefits through reduced material handling and storage costs.

Digital material tracking systems utilize RFID tags, QR codes, and inventory management software to monitor material usage, identify surplus quantities, and facilitate material sharing between projects. These systems prevent over-ordering while enabling efficient redistribution of unused materials.

Supplier partnerships that emphasize sustainable packaging, returnable containers, and take-back programs for unused materials create closed-loop systems that minimize waste while building collaborative relationships throughout the supply chain.

Material Reuse and Circular Economy Implementation

On-Site Material Recovery

Systematic deconstruction rather than demolition enables recovery of valuable materials including structural steel, dimensional lumber, brick, and architectural elements. These materials often retain significant value while reducing the need for new material production and associated environmental impacts.

Material processing and preparation facilities on sustainable construction jobsites enable cleaning, sorting, and preparation of recovered materials for reuse. These facilities can include equipment for concrete crushing, metal separation, and wood processing that transforms construction waste into valuable construction inputs.

Quality control systems for reused materials ensure that recovered components meet performance requirements while providing documentation that supports code compliance and warranty coverage. These systems often include testing protocols and certification procedures that validate material suitability for specific applications.

Regional Material Exchange Networks

Material exchange platforms connect construction projects with surplus materials to projects requiring those same materials, creating regional networks that optimize resource utilization across multiple projects. These platforms reduce waste while providing cost-effective material sources for construction projects.

Partnerships with material recovery facilities and recycling centers create outlets for construction materials that cannot be reused directly. These partnerships often include processing services that prepare materials for recycling while providing revenue streams that offset waste management costs.

Community partnerships with organizations including Habitat for Humanity provide outlets for surplus materials while supporting social objectives and community development initiatives. These partnerships create positive community relationships while extending material lifecycles.

Lean Construction Methodologies

Continuous Improvement Systems

Lean construction principles applied to sustainable construction jobsites emphasize continuous improvement through systematic waste identification and elimination. These approaches examine all construction processes to identify non-value-adding activities that consume resources without contributing to project objectives.

Value stream mapping techniques analyze material flows, information flows, and work processes to identify bottlenecks, redundancies, and inefficiencies that generate waste. These analyses often reveal opportunities for process improvements that simultaneously reduce waste and improve productivity.

Kaizen events bring together project stakeholders to identify specific improvement opportunities and implement solutions rapidly. These focused improvement initiatives often generate immediate benefits while building organizational capabilities for continuous improvement.

Pull-Based Production Systems

Pull-based construction scheduling aligns material deliveries and work activities with actual project needs rather than predetermined schedules, reducing inventory waste while improving cash flow and storage requirements. These systems require enhanced coordination but deliver substantial benefits through reduced material handling and storage costs.

Last Planner System methodologies optimize work scheduling while minimizing resource waste through improved coordination between trades and activities. These approaches reduce conflicts, delays, and rework that generate both time and material waste.

Collaborative planning approaches that include suppliers, subcontractors, and trades in scheduling decisions improve resource utilization while reducing waste from poor coordination and communication failures.

Advanced Waste Management Technologies

Automated Sorting and Processing

Robotic sorting systems can separate mixed construction waste streams automatically, improving recycling rates while reducing labor requirements for waste management. These systems utilize computer vision and artificial intelligence to identify materials and direct them to appropriate processing streams.

Mobile processing equipment enables on-site conversion of construction waste into useful products including recycled aggregates, mulch, and processed metals. This equipment reduces transportation costs while providing immediate outlets for waste materials.

Advanced tracking systems monitor waste generation rates, diversion percentages, and disposal costs to provide data that supports continuous improvement initiatives. These systems often integrate with project management software to provide real-time waste management metrics.

Digital Waste Management Platforms

Cloud-based waste management platforms coordinate waste collection, processing, and tracking across multiple projects while providing analytics that identify improvement opportunities. These platforms often include supplier networks that connect projects with appropriate waste management services.

Mobile applications enable field personnel to document waste streams, request collection services, and report waste management metrics in real-time. These applications improve data accuracy while reducing administrative overhead for waste management activities.

Blockchain technologies provide transparent tracking of waste materials throughout processing and recycling chains, ensuring accountability while supporting sustainability reporting requirements.

Environmental and Economic Benefits

Carbon Footprint Reduction

Sustainable construction jobsites typically achieve substantial carbon footprint reductions through decreased material consumption, reduced transportation requirements, and improved energy efficiency. These reductions often exceed 30-50% compared to conventional construction approaches while delivering cost savings that improve project profitability.

Lifecycle assessment methodologies quantify environmental impacts throughout material lifecycles, enabling optimization decisions that consider both immediate and long-term environmental effects. These assessments often reveal hidden environmental costs while identifying opportunities for improvement.

Carbon offset programs that utilize construction waste for beneficial uses including carbon sequestration and renewable energy generation can provide additional revenue streams while enhancing environmental performance.

Resource Conservation

Water conservation systems on sustainable construction jobsites include rainwater harvesting, greywater recycling, and efficient irrigation systems that reduce municipal water consumption while often providing cost savings through reduced utility costs.

Energy efficiency initiatives including LED lighting, efficient equipment selection, and renewable energy systems reduce operational costs while demonstrating environmental leadership that enhances corporate reputation and client relationships.

The conservation of natural resources through material reuse and recycling programs reduces pressure on extraction industries while supporting circular economy principles that benefit entire economic systems.

Regulatory Compliance and Certification

Green Building Standards

LEED, BREEAM, and other green building certification systems increasingly emphasize construction waste management as critical components of sustainable building practices. These certifications often provide market advantages while demonstrating environmental leadership.

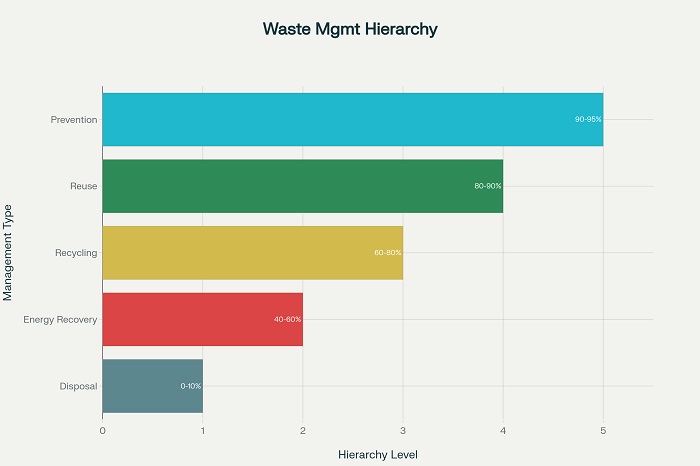

Waste diversion requirements in green building standards typically mandate 75% diversion rates from landfills, requiring comprehensive waste management planning and execution throughout construction phases.

Documentation requirements for green building certifications create permanent records of waste management performance while supporting continuous improvement initiatives and future project planning.

Environmental Regulations

Local and regional environmental regulations increasingly require construction waste management planning and reporting, making sustainable practices essential for regulatory compliance and project permitting.

Extended producer responsibility regulations hold manufacturers accountable for product end-of-life management, creating incentives for design improvements while providing support for construction waste management programs.

Future Developments and Opportunities

Technology Integration

Artificial intelligence applications will enhance waste stream optimization through predictive analytics that identify waste generation patterns and recommend prevention strategies. These systems will enable proactive waste management that prevents waste generation rather than managing it after creation.

Internet of Things sensors will provide real-time monitoring of waste generation, processing efficiency, and diversion rates while enabling immediate response to emerging issues. These systems will integrate with broader construction management platforms to provide comprehensive project oversight.

Industry Transformation

The evolution toward industrialized construction methods including prefabrication, modular assembly, and automated construction will further reduce waste generation while improving quality and productivity. These methods move much construction activity to controlled environments where waste management is more efficient and effective.

Circular economy business models that emphasize service provision rather than product sales will create incentives for manufacturers to design products for longevity, repairability, and end-of-life recovery. These models will transform construction supply chains while reducing environmental impact.

The transformation of construction toward sustainable construction jobsites represents more than environmental compliance; it embodies a fundamental shift toward resource-efficient construction that delivers superior economic and environmental performance. As these practices continue to evolve and integrate with emerging technologies, they provide construction companies with competitive advantages while contributing to global sustainability objectives. This evolution ensures that construction activities can meet growing infrastructure needs while preserving natural resources and supporting healthy communities for future generations.