The relentless pursuit of sustainable development and climate mitigation strategies has brought to the forefront the critical need for innovative biomass for carbon removal solutions. Among the several strategies, using biomass wastes to make construction materials is one that seems particularly promising. In the construction industry, these residues—which are frequently seen as waste—are finally being acknowledged for their capacity to both generate value and sequester carbon.

In addition to solving the waste management issue, using biomass wastes to make materials offers a solution to achieve carbon neutrality and zero emissions. Understanding how biomass-based solutions affect technology, the economy, and the environment is crucial as the market for sustainable building materials grows.

The Role of Biomass Residues in Sustainable Building Materials

Some examples include crop stalks, sawdust, bark, husks, and other lignocellulosic waste. Previously, these residues went to waste or were used sub optimally, leading to environmental problems like land degradation and greenhouse gas emissions from rot or combustion.

Over the past few years, there has been a paradigm change towards the use of these residues as raw materials for construction products. Given the current emphasis on carbon retention, use of residual biomass, optimization of mechanical performance, and environmental safety, products have undergone various treatments to improve fire resistance, durability, and moisture resistance – all important factors and properties in building applications. These materials have low embodied energy, are biodegradable, and can be used as carbon sinks.

The ability of biomass leftovers to store carbon into durable building materials over extended periods of time, so removing CO₂ from the atmosphere, makes this technology significant. This approach is in line with global climate policy and the basic concept of carbon accounting, which holds that a material’s life cycle retains more carbon than it emits during production and consumption.

Technological Innovations in Biomass Residue Processing

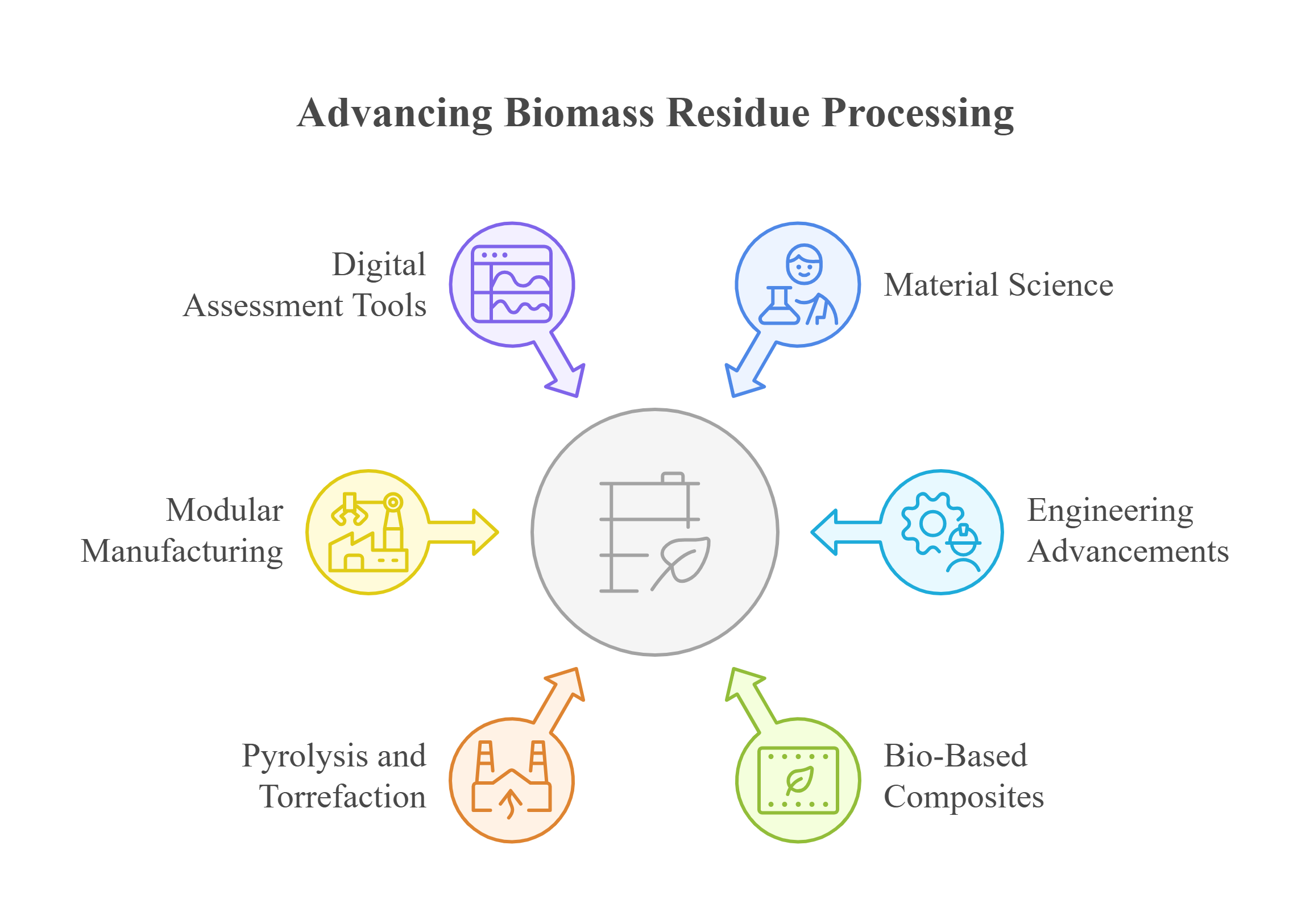

Unlocking the potential of biomass leftovers has been made possible by significant advancements in material science and engineering. Given the current emphasis on carbon retention, use of residual biomass, optimization of mechanical performance, and environmental safety, products have undergone various treatments to improve fire resistance, durability, and moisture resistance – all important factors and properties in building applications.

The development of bio-based composites, which combine biomass leftovers with binders like cementitious materials or bio-resins, is one example of such progress. Composites are substantially stronger and enhance carbon sequestration potential, while operations such as pyrolysis and torrefaction advance, allowing biomass residues to be processed into biochar. To more rapidly and efficiently lock away carbon, biochar may be added to cement or utilized as an insulating substance.

Availability of modular manufacturing capabilities and scalable technologies have also further reduced costs and improved the market positioning of bio-based building materials. Moreover, the availability of digital methods of assessing property performance (e.g., life cycle assessment (LCA) software) has made analyzing environmental impacts easier, therefore manufacturers and consumers can make informed decisions.

Market Potential

The market for biomass residue-based sustainable building materials is expanding quickly as a result of increased regulatory pressure, consumer demand for eco-friendly building materials, and emerging technology. With governments and industry giants making net-zero carbon commitments, the market for carbon-negative and low-carbon construction materials is set to accelerate.

The growth will be driven by greater adoption across commercial, residential, and infrastructure applications. Where biomass resources are plentiful, including in North America, South America, and some areas of Europe and Asia, the growth in the market is likely to be strongest.

Also, large-scale infrastructure projects pursuing sustainability certification and green building codes will serve as triggers, spurring the adoption of biomass residues in mainstream construction activities. Investment in research and development, policy support, and public-private partnerships will also help promote market development.

Environmental and Climate Benefits

Using biomass residues to make construction goods has several positive environmental effects. Most importantly, it creates a carbon sink by sequestering CO₂ from the atmosphere in a durable material. Unlike traditional construction materials like concrete and steel, which are energy-intensive and emit substantial greenhouse gases, biomass-based products often have a lower embodied energy footprint.

Additionally, by replacing products made from fossil fuels with biomass waste, the use of biomass waste in production may lower overall emissions. By converting garbage into constructed material, methane—a powerful greenhouse gas—can be released during open field burning or landfilling, reducing environmental issues.

The potential for lifecycle carbon negativity is an additional significant advantage. Biomass residues can continually remove CO₂ from the atmosphere if they are managed properly, especially if agricultural or forest residues are collected and regrown sustainably. This provides a constant carbon removal cycle that plays a large role in climate mitigation strategies.

Challenges and Limitations

The extensive use of biomass residue building materials for carbon removal is hampered by a number of issues, despite the encouraging potential. The first logistical difficulty is the availability of biomass residues and the logistics involved in getting them into a supply chain. Agricultural, forestry, and industrial sectors must work together to ensure a steady supply of high-quality feedstock.

Second, the concerns over technological maturity remain. The possibilities are encouraging, but much of the biomass processing technologies are still only in developmental or pilot-project stages. Scaling from the development of these technologies to commercial production will require significant capital investment; refining the technology, and complying with regulatory policy.

Lastly, there are durability and performance issues to contend with. Some biomass products will come with limitations on moisture sensitivity, performance with respect to fire, and structural integrity over the long term. Compliance with building codes and standards requires an aggressive testing program, certification, and, at times, adjustments to materials.

Environmental factors also include the sustainability of the biomass harvests. Irresponsible harvesting can contribute to deforestation, biodiversity loss, and soil erosion which would eliminate the carbon removal benefits. So that’s why lifecycle assessments and sustainably sourced materials are critical.

Lastly, economic considerations like production costs, market acceptance, and competition with incumbent building materials determine market penetration. Production costs being higher initially compared to traditional materials pose a limitation, but increasing with technological developments and policy support, the difference is likely to decrease.

Incorporating biomass residue into building materials will be a significant way for the construction industry to support global climate goals in the future. Advances in bioprocessing and supportive legislation will be essential in overcoming future challenges.

One strategy is hybridise materials made from biomass residues and other low-carbon (or carbonized) materials (e.g., recycled steel or carbon-enriched concrete) for even more optimized carbon sequestration. The development of regional biomass supply centers and circular economy practices will also enhance raw material sustainability.

Collaboration amongst industry partners, governments, and research agencies will drive research and development, standardization and market uptake. Certification programs and building codes that acknowledge and reward carbon-negative products can encourage take-up.

As the world ramps up in pursuit of net-zero emissions, biomass residue building products—and the carbon capture they facilitate—are on the cusp of making a critical contribution. Scaling those solutions sustainably, economically, and efficiently to make them a central part of future-proofed infrastructure will be the challenge.

Future Outlook and Strategic Opportunities

Looking forward, the integration of biomass residues into building materials represents a significant opportunity for the construction industry to contribute meaningfully to climate goals. Innovations in bioprocessing, along with supportive policies, will be instrumental in overcoming existing barriers.

One strategic avenue involves the development of hybrid materials that combine biomass residues with other low-carbon materials such as recycled steel or carbon-infused concrete, to further enhance their carbon sequestration potential. Additionally, establishing regional biomass supply hubs and fostering circular economy approaches will ensure sustainable raw material sourcing.

Partnerships among industry players, governments, and academia will accelerate research and development, facilitate standardization, and promote market acceptance. Building codes and certification schemes that recognize and reward carbon-negative materials can incentivize adoption.

As the global community intensifies its efforts toward net-zero emissions, biomass residue building products—and the carbon removal they enable—are poised to play a vital role. The challenge lies in scaling these solutions sustainably, efficiently, and economically, ensuring they become a core element of future-proofed infrastructure.

Conclusion

Using biomass residues in building materials represents a powerful opportunity to transform a waste into an important solution for climate change. Biomass for carbon removal is sequestered in durable building materials and this action fulfills the high level goal of reducing greenhouse gases and fighting climate change. Technology, logistical, and regulatory challenges may remain, but new ideas, good policy, and market forces suggest that carbon-negative building materials are in our future.

The journey toward sustainable, carbon-negative construction materials is still in its early stages, but with concerted effort, collaboration, and investment, biomass residues can significantly contribute to global carbon removal targets. Through continued industry development, the solutions may redefine the place of waste within the circular economy and solidify biomass’s role as a pillar of climate mitigation efforts.