Floating docks have become the gold standard for modern waterfronts, offering unmatched flexibility, resilience and long-term value for developments. For construction professionals, choosing the best floating docks for marinas can make or break a project’s success.

Here are the top manufacturers trusted by the industry, comparing features, compliance and support to help build future-ready moorings in any environment.

1. EZ Dock

EZ Dock is a global leader in the design and supply of modular floating dock solutions, perfectly suited for marinas and waterfront developments. Since 1991, the company has pioneered material innovations such as rotomolded polyethylene sections, built to withstand the harshest weather while minimizing maintenance for marina operators.

EZ Dock products cover a wide array of commercial applications, offering end-to-end support from project planning through installation. Its floating docks are renowned for their long lifespan and are easy to reconfigure or expand with additional modules. Eco-friendly production and ADA-compliant solutions are additional reasons why marinas, resorts and public sector clients turn to EZ Dock when choosing the best floating docks.

Key features:

- Modular design allows for rapid expansion and future-proofing of marina layouts

- ADA-compliant platforms and specialized launch systems expand access to all user groups

- Industry-leading support for project engineering, permitting and site-specific adaptations

- Eco-friendly, UV-resistant construction reduces environmental risk and maintenance costs

2. AccuDock

AccuDock specializes in custom-engineered floating dock systems with a strong focus on meeting the rigorous demands of commercial construction. Manufactured in the U.S., its platforms serve as durable, low-maintenance solutions for marinas, yacht clubs, rowing venues and industrial waterfronts. Offerings range from aluminum-framed docks to high-buoyancy polyethylene pontoons, designed to meet site-specific load requirements and withstand extreme environmental conditions.

Construction professionals benefit from AccuDock’s comprehensive support in design, fabrication and logistics, ensuring tailored solutions that adhere to project timelines and regulatory standards.

Key features:

- Custom engineering for complex, high-traffic marina environments

- Heavy-duty platforms support high vessel loads and frequent pedestrian access

- Wide choice of decking surfaces, including hardwood and composite options

- In-house design-build team for seamless project collaboration

3. The Dock Doctors

The Dock Doctors offers custom floating systems, specifically crafted for the commercial marina market. Based in the Northeastern U.S., the company’s reputation is built on providing robust, site-adapted solutions using aluminum, steel or wood frames paired with proven flotation technology. It handles projects from feasibility assessment to full installation, accommodating challenging waterfronts, fluctuating water levels and demanding conditions.

The company’s ability to customize layouts and integrate unique access requirements means it can deliver maximum operational uptime in both private and public marina environments.

Key features:

- Expertise in project planning for challenging terrain and variable water conditions

- Complete systems, including gangways, access bridges and anchoring

- Personalized layouts and CAD-based design support for contractors

- Emphasis on long-term durability to reduce life cycle maintenance costs

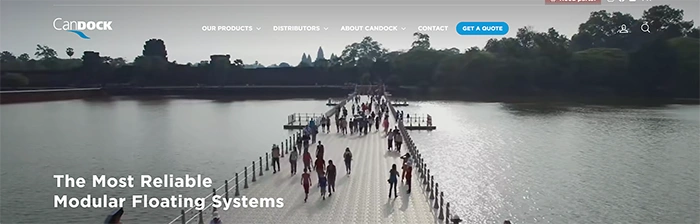

4. Candock

Candock is a global force in modular, cube-based dock systems, serving major marina developers and industrial waterfronts worldwide. Its proprietary polyethylene cubes form floating platforms that can be configured for virtually any purpose, including slips, wave attenuators, work platforms and waterside infrastructure.

The Candock system is valued for its quick installation, absence of metal corrosion risks and ability to adapt to changing water levels. Construction professionals benefit from ease of transport, on-site assembly and the potential to scale or reconfigure as the business grows.

Key features:

- The modular cube system enables flexibility and easy future expansion

- Almost maintenance-free design resists ice, UV, chemicals and salt water

- Lightweight for shipping but engineered for professional, high-load applications

- Offers specialized accessories for marina management, such as cleats, fendering and utility service cubes

5. Wave Armor

Wave Armor delivers robust, resort-grade floating dock systems, engineered for maximum stability — ideal for exposed locations. Its premium rotomolded polyethylene platforms have aesthetics that complement upscale developments and provide safety and comfort for marina users.

Contractors and project designers can select from a comprehensive range of accessories, including kayak launches, swim platforms and gangways, ensuring every detail is covered. Wave Armor is particularly well regarded for its ability to withstand high-impact environments while minimizing long-term maintenance costs.

Key features:

- Robust, foam-filled floats for maximum stability

- Luxury, slip-resistant modular surfaces

- Wide selection of pre-engineered accessories and features for turnkey builds

- Designed for easy integration with utilities and shoreline access systems

6. Bellingham Marine

Bellingham Marine is a premier full-service contractor specializing in turnkey concrete and aluminum floating dock systems for complex infrastructures. Its portfolio spans public harbors, mega-yacht marinas and commercial ports, offering complete design-build solutions from concept to commissioning.

Bellingham’s installations are engineered for the highest standards of flotation, stability and load-bearing, while the company’s global project management team ensures compliance, efficiency and world-class execution for major projects.

Key features:

- Turnkey marina construction, from planning and permitting to installation

- Patented concrete floating dock technology for superior stability and lifespan

- Experience in large-scale, multi-phase and international projects

- Comprehensive aftercare and maintenance programs are available

7. ShoreMaster

ShoreMaster delivers high-quality floating docks well-suited for commercial marina deployment, with a focus on flexibility, simple assembly and enduring good looks. Its PolyDock and RhinoDock lines both provide the strength needed to safely accommodate large vessels.

Construction professionals have access to ShoreMaster’s extensive dealer resources and hands-on project guidance, making for streamlined implementation even on tight schedules. The company excels in modularity, allowing for custom shapes and easy future expansion.

Key features:

- Robust aluminum and poly deck construction proven in commercial marinas

- Modular design for rapid assembly and flexible configuration

- Support for full utility integration and custom finishes

- Long-standing U.S. manufacturing reputation with strong client support

8. Connect-A-Dock

Connect-A-Dock produces versatile, modular dock sections suitable for marinas, utilities, and municipal applications. Made from high-strength, UV-resistant polyethylene, its units are designed for quick installation and adaptability — virtually any size or footprint is possible.

Professional builders will appreciate Connect-A-Dock’s minimal environmental disruption and ease of reconfiguration as occupancy needs change. Wide accessory availability includes cleats, bumpers, railings and connection hardware, providing everything to outfit a modern marina project.

Key features:

- Tool-free installation and reconfiguration, saving labor costs and time

- High-impact, nonskid surface ensures user safety

- Docks adapt to changing water levels

- Compatible accessories for mooring, access and safety are readily available

Comparing the Best Floating Docks for Marinas

Featured companies were selected for their established reputations and proven project experience in the marina construction industry. Research combined industry recommendations, company documentation and project portfolios. Emphasis was placed on construction materials, durability and technical innovation, as relevant to commercial waterfronts.

| Company | Material and Construction | ADA and Accessibility | Wave/Load Handling | Project Services |

| EZ Dock | Rotomolded polyethylene | Industry-leading ADA-compliance and EZ Launch system | Moderate/High | Extensive dealer network, site support and planning tools |

| AccuDock | Aluminum and poly decking | Custom ADA ramps | High | Full in-house design-build service |

| The Dock Doctors | Aluminum, steel, wood | Options available | High | Project management and installation |

| Candock | Polyethylene cube modular | Options available | Moderate | Dealer/distributor installation, planning aid |

| Wave Armor | Rotomolded polyethylene | Options available | High | Wide accessory range, dealer support |

| Bellingham Marine | Concrete, aluminum, wood, steel | Yes | High | Full turnkey services |

| ShoreMaster | Aluminum and poly decking | Options available | Moderate | Dealer-based design and installation |

| Connect-A-Dock | Polyethylene modular | Options available | Moderate | Dealer service support |

Why Floating Docks Are the Smart Choice for Modern Marinas

Unlike traditional fixed piers, floating docks automatically adjust to changing water levels, providing consistent access for boaters in tidal areas, reservoirs and bodies of water with fluctuating surfaces. This adaptability significantly reduces the risk of damage during storms, flooding or seasonal changes, resulting in lower maintenance costs and fewer operational disruptions for owners.

Additionally, the best floating docks for marinas are faster and easier to install, requiring less invasive groundwork and permitting. A modular design enables easy expansion or reconfiguration, supporting long-term growth without the need for expensive renovations.

Many modern systems utilize environmentally friendly materials, thereby minimizing their impact on sensitive aquatic ecosystems. Today’s top floating docks offer impressive load capacities, robust stability and customizable options for utilities, lighting and ADA accessibility.

Key Considerations When Specifying Floating Docks for Marinas

Selecting the best floating docks is crucial for a long-lasting operation. Construction professionals and engineers should take a holistic approach, weighing critical site factors alongside project goals to ensure optimal value and performance. Primary considerations include:

1. Site and Environmental Conditions

Evaluate water depth, tidal ranges, wave exposure, wind fetch and seasonal changes. Exposure to storms, ice or heavy boat traffic may dictate specific materials or anchoring solutions.

2. Regulatory and Accessibility Requirements

Compliance with local, state and federal regulations, including ADA accessibility guidelines, is essential. Consider features like ADA-compliant gangways, ramps and accessible launch systems.

3. Load Capacity and Usage Needs

Factor in the expected weight of boats, vehicular access needs — for fueling or emergency services – and the number of users. Heavier commercial applications may require reinforced structures or special flotation options.

4. Expansion and Adaptability

Select modular systems that accommodate future growth or reconfiguration. Flexibility allows the dock to adapt efficiently to shifting customer demands or changing water conditions.

5. Utility Integration and Amenities

Plan for electric, water and fuel lines, safety features, such as lighting or fire suppression, and customer amenities. Choose systems with built-in utility troughs or channels.

6. Long-Term Maintenance and Durability

Compare materials for resistance to UV exposure, rot, marine growth, corrosion and impact. Lower life cycle maintenance can save significant costs over time.

By addressing these key considerations early in the planning phase, marina developers can ensure their floating dock investments are sound, future-ready and positioned for long-term operational success.

Sustainability and Environmental Impact of Floating Docks

Environmental stewardship is becoming a core priority in marina design and construction, driven by regulatory demands and the growing expectations of boaters and waterfront communities. Certifications like the Blue Flag and LEED require waterfronts to minimize ecological disruption, manage water quality and support local biodiversity.

As a result, many floating dock manufacturers now offer systems built with fully recyclable, nontoxic materials — such as rotomolded polyethylene or sustainably sourced aluminum — that do not leach harmful chemicals into the water. The best floating docks can also help with stormwater management, featuring permeable surfaces or integrated collection channels to reduce runoff and erosion.

Selecting sustainable floating dock solutions improves a marina’s environmental footprint and can also enhance public reputation, attract eco-conscious clientele and simplify compliance with evolving regulations.

ADA-Compliance and Accessibility for Marinas

Floating docks present unique opportunities — and challenges — when it comes to meeting accessibility standards. In the U.S.:

- Gangways must be designed to remain as accessible as possible despite changing water levels — for example, with slopes that adjust as water rises or falls.

- Transfer systems and adaptive boat launches for kayaks and canoes allow users with mobility limitations to safely enter and exit watercraft directly from the floating dock.

- Edge protection, handrails and surface treatments should prevent slips and provide continuous support along all accessible routes.

Seek modular floating dock systems engineered for accessible connections between land and water, adaptable for ADA-compliant widths, surfaces and railings. Factor in all users — families with strollers, aging boaters and wheelchair users — when specifying layouts and materials.

Floating docks with inclusive access attract a wider customer base and support community events, youth programs and adaptive sports. Well-executed accessibility meets or exceeds legal requirements and also protects a dock investment by future-proofing the marina as standards continue to evolve.

Turnkey Solutions vs. Modular-Based Approach

As marina developments grow in scale and complexity, many construction professionals are turning to turnkey floating dock providers for more efficient project delivery. Turnkey services go beyond supplying waterfront components — they encompass the full project life cycle, from site assessment and custom design to permitting support, manufacturing, installation and even long-term maintenance.

This integrated approach reduces risk because experienced turnkey partners bring technical expertise and regulatory knowledge, ensuring docks are compliant with all local and federal standards.

However, the turnkey approach limits opportunities to compare competitive bids on each project phase. It is also typically more expensive overall than a modular-based or owner-managed construction approach.

Developers who have specific construction standards or strong in-house teams may find the modular-based approach more flexible and accommodating. Modular builds also enable developers to work with local contractors who have unique knowledge of regional permitting or site-specific environmental issues.

Finding the Best Floating Docks for Any Marina Project

Selecting the right floating dock partner is a pivotal decision that shapes the safety, flexibility and long-term success of a marina. By focusing on materials, adaptability, accessibility and proven manufacturing, professionals can deliver waterfronts that are inviting, future-ready and environmentally responsible.