Commercial & Industrial Lighting Innovations Driving Energy Efficiency

The commercial and industrial sectors represent the largest consumers of lighting energy within the built environment, creating unprecedented opportunities for energy efficiency improvements through innovative lighting technologies and control systems. As energy costs continue rising and environmental regulations become increasingly stringent, industrial lighting innovations have emerged as critical components of corporate sustainability strategies while delivering substantial operational cost reductions and performance improvements.

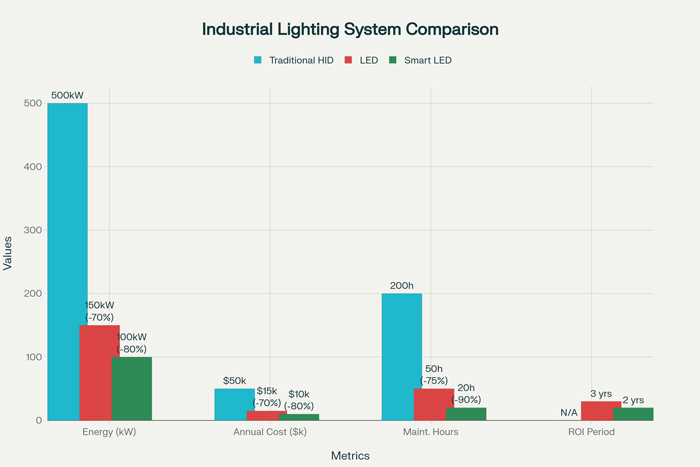

This technological revolution extends far beyond simple fixture replacement to encompass comprehensive lighting ecosystems that integrate advanced LED technology, intelligent control systems, and sophisticated monitoring capabilities designed to optimize energy consumption while maintaining superior illumination quality for demanding industrial and commercial applications. The convergence of these technologies creates lighting solutions that not only reduce energy consumption by 70-80% compared to traditional systems but also enhance workplace safety, productivity, and operational flexibility.

LED Technology Transformation in Industrial Environments

The adoption of Light Emitting Diode technology in industrial applications has fundamentally transformed how large-scale facilities approach lighting design and energy management, delivering dramatic efficiency improvements while enhancing illumination quality and reducing maintenance requirements. Industrial LED systems provide exceptional durability and performance characteristics that exceed traditional lighting technologies while operating reliably in challenging environmental conditions including extreme temperatures, humidity, vibration, and chemical exposure.

High-bay LED fixtures designed for industrial applications deliver luminous efficacies exceeding 150 lumens per watt while providing uniform light distribution across large floor areas typical of manufacturing facilities, warehouses, and distribution centers. These fixtures eliminate the hot spots and dark areas commonly associated with traditional high-intensity discharge lighting while providing instant-on capability and flicker-free operation that enhances worker comfort and productivity.

The exceptional lifespan of industrial LED fixtures, often exceeding 100,000 hours of operation, dramatically reduces maintenance interventions and associated labor costs while minimizing production disruptions caused by lighting failures. This extended operational life proves particularly valuable in facilities with high ceilings or difficult-to-access mounting locations where maintenance activities are complex and expensive.

Thermal management innovations in industrial LED fixtures ensure consistent performance and extended lifespan even in high-temperature environments common in manufacturing facilities. Advanced heat sink designs, improved thermal interface materials, and intelligent thermal monitoring systems prevent performance degradation while maintaining optimal light output throughout the fixture’s operational life.

Color rendering improvements in industrial LED systems enhance visual acuity and safety in manufacturing environments where accurate color perception is critical for quality control, safety compliance, and worker performance. High color rendering index LED sources ensure that colors appear natural and accurate while maintaining energy efficiency characteristics.

Smart Control Systems and Automation

Intelligent lighting control systems represent the next frontier in industrial lighting efficiency, enabling facilities to optimize energy consumption through sophisticated monitoring, scheduling, and adaptive control capabilities that respond automatically to changing operational requirements and environmental conditions. These systems provide unprecedented visibility into lighting energy consumption while enabling precise control over individual fixtures or lighting zones.

Occupancy-based lighting control systems utilize advanced sensor technologies including passive infrared, ultrasonic, and microwave detection to ensure lighting operates only in occupied areas while maintaining appropriate illumination levels for safety and productivity. These systems can differentiate between various types of activity and adjust lighting accordingly, providing bright illumination for active work periods and reduced lighting for maintenance or security functions.

Daylight harvesting systems integrated with industrial lighting controls automatically adjust artificial lighting output based on available natural light, maximizing energy savings while maintaining consistent illumination levels throughout varying daylight conditions. These systems prove particularly effective in facilities with significant glazing areas or skylights where natural light contribution varies throughout the day.

Demand response capabilities enable industrial lighting systems to participate in utility demand management programs, automatically reducing energy consumption during peak demand periods while maintaining minimum illumination levels required for safety and operations. These programs can provide substantial cost savings through reduced demand charges and utility incentive payments.

Predictive maintenance capabilities integrated within smart lighting systems monitor fixture performance and provide advance warning of potential failures, enabling proactive maintenance scheduling that prevents unexpected lighting outages while optimizing maintenance resource allocation. These systems track operating hours, electrical characteristics, and performance metrics to predict maintenance needs accurately.

Energy Management and Cost Optimization

The implementation of advanced energy management strategies within commercial and industrial lighting systems creates opportunities for substantial operational cost reductions while supporting broader corporate sustainability objectives and regulatory compliance requirements. These strategies encompass both technological solutions and operational practices that maximize energy efficiency while maintaining optimal illumination conditions.

Real-time energy monitoring systems provide detailed visibility into lighting energy consumption patterns, enabling facility managers to identify opportunities for additional efficiency improvements while tracking progress toward energy reduction goals. These systems can identify unusual consumption patterns that may indicate equipment problems or operational inefficiencies requiring attention.

Load scheduling capabilities enable facilities to optimize lighting energy consumption based on utility rate structures, operational schedules, and demand management requirements. These systems can automatically adjust lighting levels during peak rate periods while maintaining minimum illumination levels required for safety and productivity.

Energy benchmarking capabilities compare facility lighting energy consumption against industry standards and similar facilities, identifying opportunities for performance improvements while supporting energy management certification programs and regulatory reporting requirements. These comparisons help establish realistic efficiency targets while justifying investments in lighting upgrades.

Peak demand management through intelligent lighting control can significantly reduce utility demand charges, which often represent substantial portions of commercial and industrial electricity costs. Automated demand response systems can temporarily reduce lighting levels during peak demand periods while maintaining safety-compliant illumination levels.

Safety and Productivity Enhancement

Industrial lighting innovations contribute significantly to workplace safety and productivity through improved illumination quality, reduced maintenance requirements, and enhanced environmental conditions that support worker performance and wellbeing. These benefits often justify lighting investments independently of energy savings while providing additional value that supports overall operational objectives.

Improved light quality characteristics of LED systems including better color rendering, reduced flicker, and more uniform light distribution enhance visual acuity and reduce eye strain among workers performing detailed tasks. These improvements can reduce error rates, improve quality control, and enhance overall productivity while supporting worker health and satisfaction.

Enhanced safety outcomes result from more reliable lighting systems that eliminate the periodic failures common with traditional lighting technologies while providing better illumination quality for hazard identification and emergency response. LED systems provide instant-on capability that eliminates the warm-up period required by traditional high-intensity discharge fixtures.

Reduced maintenance activities decrease worker exposure to maintenance-related hazards including falls from heights, electrical hazards, and equipment-related injuries. The extended lifespan of LED fixtures minimizes the frequency of maintenance interventions while reducing associated safety risks and operational disruptions.

Emergency lighting integration capabilities enable industrial LED systems to provide backup illumination during power outages while maintaining energy efficiency during normal operations. These integrated systems eliminate the need for separate emergency lighting fixtures while ensuring compliance with safety regulations.

Environmental Benefits and Sustainability

The environmental benefits of industrial lighting innovations extend beyond energy efficiency to encompass reduced environmental impact throughout the lighting system lifecycle, from manufacturing through disposal, while supporting corporate sustainability goals and environmental reporting requirements. These benefits contribute to improved corporate environmental performance while reducing regulatory compliance costs.

Reduced carbon emissions from lower energy consumption directly support climate change mitigation goals while reducing facility carbon footprints and supporting carbon neutral objectives. The magnitude of emission reductions from industrial lighting upgrades often represents significant portions of overall facility environmental improvements.

Elimination of hazardous materials including mercury found in traditional fluorescent and high-intensity discharge lighting reduces environmental risks associated with fixture disposal while simplifying waste management procedures. LED fixtures contain no hazardous materials and can be recycled at end-of-life.

Reduced packaging and transportation impacts result from the extended lifespan of LED fixtures, which require replacement far less frequently than traditional lighting technologies. This longevity reduces the environmental impact associated with manufacturing, packaging, and transporting replacement fixtures throughout the system lifecycle.

Light pollution reduction through precise optical control available with LED systems minimizes environmental impact on surrounding ecosystems while improving lighting efficiency and reducing energy consumption. Advanced optical designs can direct light precisely where needed while eliminating light trespass and upward light emission.

Implementation Strategies and Return on Investment

Successful implementation of industrial lighting innovations requires comprehensive planning that considers operational requirements, financial constraints, and integration with existing facility systems while ensuring maximum return on investment and performance benefits. These implementation strategies must balance initial costs with long-term operational benefits while minimizing disruption to ongoing operations.

Phased implementation approaches enable facilities to spread investment costs over multiple budget cycles while gaining experience with new technologies and validating performance benefits before proceeding with comprehensive upgrades. These phased approaches can prioritize areas with highest energy consumption or greatest operational benefits.

Financing options including utility rebates, energy service company arrangements, and equipment leasing programs can improve project economics while reducing upfront investment requirements. These financing mechanisms often enable projects that might not otherwise meet internal return on investment criteria while providing predictable operational cost reductions.

Performance verification through commissioning and ongoing monitoring ensures that lighting systems deliver expected energy savings and performance benefits while identifying opportunities for optimization and improvement. These verification activities protect investment returns while ensuring continued optimal performance throughout the system lifecycle.

Training programs for facility maintenance staff ensure proper operation and maintenance of advanced lighting systems while maximizing system performance and lifespan. These programs should cover both routine maintenance procedures and troubleshooting techniques that enable quick resolution of any performance issues.

The continued evolution of industrial lighting innovations promises even greater efficiency improvements, enhanced functionality, and improved integration capabilities as technology advances and costs continue declining. These developments will make advanced lighting systems increasingly accessible to facilities of all sizes while delivering ever-greater benefits in terms of energy efficiency, operational performance, and environmental sustainability.

This transformation represents a fundamental shift toward more intelligent, efficient, and responsive industrial environments that support productivity, safety, and sustainability objectives while reducing operational costs and environmental impact. As these technologies continue advancing and becoming more affordable, they will become standard elements of industrial facility design and operation, contributing to more sustainable and efficient industrial operations worldwide.