Smart Construction Tech: Drones, IoT, Sensors & Productivity Insights

The construction industry is experiencing an unprecedented transformation as smart construction technology revolutionizes traditional building practices. The integration of drones, Internet of Things (IoT) sensors, and advanced monitoring systems is creating intelligent jobsites that optimize productivity, enhance safety, and provide real-time insights into construction operations. This technological convergence is establishing new standards for project management, quality control, and operational efficiency that define the future of construction.

The Digital Construction Revolution

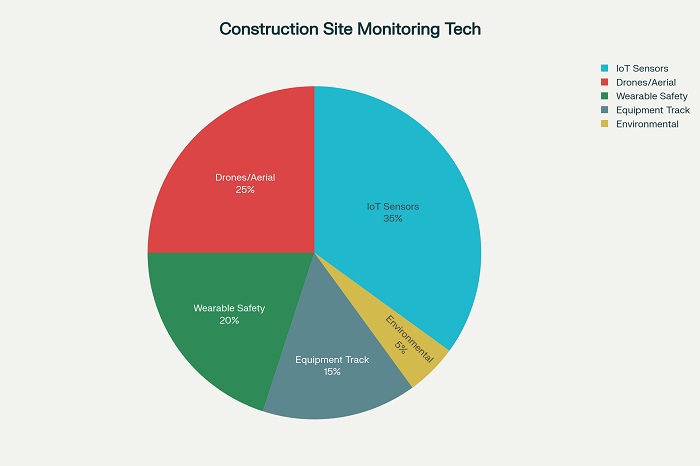

Smart construction technology represents the convergence of multiple technological streams that together create construction environments far more capable than the sum of their individual components. The global IoT in construction market has experienced explosive growth, expanding from $12.2 billion in 2024 to a projected $31.3 billion by 2033, reflecting the industry’s rapid adoption of connected technologies.

This digital transformation enables construction projects to operate with unprecedented visibility and control, transforming job sites from reactive environments into proactive, data-driven operations. The integration of multiple sensor types, aerial monitoring systems, and predictive analytics creates comprehensive situational awareness that enables informed decision-making at all project levels.

Drone Technologies Transforming Aerial Intelligence

Advanced Imaging and Surveying Capabilities

Unmanned aerial vehicles equipped with high-resolution cameras, LiDAR sensors, and thermal imaging capabilities have revolutionized site surveying and progress monitoring. Modern construction drones can capture detailed site data in hours rather than the days or weeks required for traditional surveying methods, while providing accuracy levels that meet engineering specifications for most construction applications.

LiDAR-equipped drones generate precise three-dimensional point clouds that enable accurate volume calculations, topographic mapping, and progress verification. These systems can detect millimeter-level changes in site conditions, providing early identification of potential issues including settlement, erosion, or construction deviations from design specifications.

Thermal imaging capabilities enable drones to identify moisture infiltration, energy losses, and equipment overheating that would be invisible to traditional inspection methods. This capability is particularly valuable for building envelope assessment and mechanical system evaluation during construction phases.

Real-Time Progress Monitoring

Drone-based progress monitoring systems utilize computer vision and artificial intelligence to automatically compare actual construction progress against project schedules and Building Information Models (BIM). These systems generate progress reports that identify ahead-of-schedule and behind-schedule activities with accuracy that enables proactive management intervention.

The integration of drone data with cloud-based project management platforms enables stakeholders to access current site conditions from any location, facilitating remote collaboration and decision-making. High-resolution imagery and 3D models provide comprehensive site documentation that supports accurate progress assessment and change order validation.

Automated flight planning ensures consistent data collection protocols that enable reliable progress comparisons over time. GPS-guided flight paths and standardized imaging procedures create repeatable documentation that supports statistical analysis of construction productivity and quality trends.

IoT Sensor Networks Enabling Smart Monitoring

Environmental and Safety Monitoring

IoT sensor deployments throughout construction sites provide continuous monitoring of environmental conditions including air quality, noise levels, dust concentrations, and weather parameters. These systems enable immediate response to hazardous conditions while providing documentation for regulatory compliance and worker safety programs.

Wearable sensor devices monitor worker vital signs, location, and activity levels to identify potential safety hazards including heat stress, falls, and exposure to hazardous conditions. Smart helmets and safety vests incorporate sensors that detect impacts, unusual movements, and environmental hazards while providing communication capabilities for emergency response.

Environmental sensors placed strategically throughout job sites monitor dust levels, vibration, and noise to ensure compliance with local regulations while minimizing impact on surrounding communities. Real-time alerts enable immediate corrective action when environmental limits are exceeded.

Equipment and Asset Tracking

IoT-enabled equipment monitoring provides real-time visibility into machinery location, operating status, and maintenance requirements. These systems reduce equipment theft, optimize utilization rates, and enable predictive maintenance approaches that minimize downtime and repair costs.

Smart sensors on construction equipment monitor operating parameters including engine performance, hydraulic system pressure, and wear component condition. This data enables maintenance scheduling based on actual equipment condition rather than arbitrary time intervals, reducing maintenance costs while improving equipment reliability.

Material tracking systems utilize RFID tags and GPS sensors to monitor inventory levels, delivery schedules, and material consumption rates. These systems reduce material waste, prevent theft, and ensure that required materials are available when needed for construction activities.

Advanced Analytics and Productivity Insights

Artificial Intelligence and Machine Learning Applications

AI-powered analytics systems process vast quantities of data from multiple sources to identify patterns, predict potential issues, and optimize construction operations. Machine learning algorithms analyze historical project data to improve scheduling accuracy, resource allocation, and risk assessment capabilities.

Computer vision systems analyze video feeds from security cameras and drones to monitor safety compliance, track worker productivity, and identify potential hazards automatically. These systems can detect workers not wearing required personal protective equipment, unsafe behaviors, and hazardous site conditions without human supervision.

Predictive analytics models utilize data from sensors, weather forecasts, and historical performance to forecast potential delays, safety risks, and quality issues before they impact project outcomes. These insights enable proactive management approaches that prevent problems rather than responding to them after they occur.

Real-Time Decision Support Systems

Smart construction technology platforms integrate data from multiple sources to provide comprehensive dashboards that enable informed decision-making at all project levels. These systems present complex data in intuitive formats that support rapid assessment and response to changing conditions.

Digital twin technologies create dynamic virtual representations of construction projects that update continuously based on sensor data and progress information. These models enable simulation of different scenarios and optimization of construction sequences before committing resources to specific approaches.

Mobile applications provide field personnel with access to real-time data, digital drawings, and communication tools that enable immediate response to changing conditions. These systems reduce the time between issue identification and resolution while ensuring that all stakeholders have access to current project information.

Integrated Communication and Collaboration Systems

5G Connectivity and Edge Computing

The deployment of 5G networks enables high-bandwidth, low-latency communication that supports real-time data transfer from IoT sensors, cameras, and other monitoring devices. This connectivity enables remote control of autonomous machinery and supports advanced augmented reality applications for design review and construction guidance.

Edge computing systems process data locally to reduce latency and bandwidth requirements while enabling immediate response to time-critical conditions. These systems can identify safety hazards, equipment failures, and quality issues within seconds of occurrence, enabling immediate corrective action.

The integration of artificial intelligence with edge computing enables smart construction technology systems to learn from experience and continuously improve their performance. These systems can adapt to specific project conditions and requirements while maintaining consistent performance standards.

Enhanced Project Coordination

Smart construction technology platforms facilitate seamless collaboration between project stakeholders including owners, architects, engineers, contractors, and subcontractors. Shared data platforms ensure that all participants have access to current project information while maintaining appropriate security and access controls.

Real-time communication systems enable immediate coordination of construction activities, reducing delays and conflicts between different trades and activities. These systems support dynamic scheduling adjustments that optimize productivity while maintaining quality and safety standards.

The integration of smart construction technology with Building Information Modeling creates comprehensive project management environments that support decision-making throughout the entire project lifecycle. These systems provide audit trails and documentation that support project closeout and facilities management activities.

Quality Control and Verification Systems

Automated Inspection Technologies

Smart sensors and imaging systems enable automated quality control inspections that identify dimensional deviations, material defects, and construction errors with accuracy exceeding traditional manual inspection methods. These systems provide objective documentation of construction quality while reducing inspection time and costs.

Robotic inspection systems can access confined spaces and hazardous areas that would be dangerous or impossible for human inspectors to evaluate. These systems provide comprehensive documentation of hidden conditions including structural connections, utility installations, and waterproofing details.

The integration of inspection data with project management systems enables immediate response to quality issues while providing trending data that identifies systemic problems and improvement opportunities. This approach prevents quality issues from compounding while reducing rework and associated costs.

Future Technological Integration

Autonomous Systems and Robotics

The evolution of smart construction technology points toward increasing automation of construction processes through robotic systems that operate under the guidance of sensor networks and artificial intelligence. These systems will enable continuous construction operations while maintaining safety and quality standards.

Swarm robotics applications will enable coordinated activities between multiple autonomous systems, optimizing material handling, site preparation, and construction sequencing. These systems will operate under the oversight of smart construction technology networks that ensure safety and coordinate activities with human workers.

Advanced Material Integration

Smart materials that incorporate sensors and communication capabilities will enable real-time monitoring of structural performance, environmental conditions, and maintenance requirements throughout building service life. These materials will extend smart construction technology capabilities beyond the construction phase into long-term facility management.

The integration of smart construction technology with advanced manufacturing systems including 3D printing and prefabrication will enable more precise construction methods while reducing waste and improving quality. These systems will operate under the guidance of AI-powered optimization algorithms that continuously improve performance.

The transformation of construction through smart construction technology represents more than technological advancement; it embodies a fundamental shift toward data-driven construction that optimizes every aspect of the building process. As these technologies continue to mature and integrate, they promise to establish construction practices that achieve new levels of efficiency, safety, and quality while providing the flexibility to adapt to changing requirements and conditions. This evolution ensures that the construction industry can meet the challenges of urbanization, climate change, and resource constraints while delivering the infrastructure required for sustainable development and economic growth.