In the ever-evolving world of construction, a new player has entered the arena and is significantly transforming how things are done – CNC machines. These automated wonders are not just enhancing efficiency but also rewriting the construction industry’s norms, forging a path towards an innovative, sustainable future.

Understanding CNC Machines

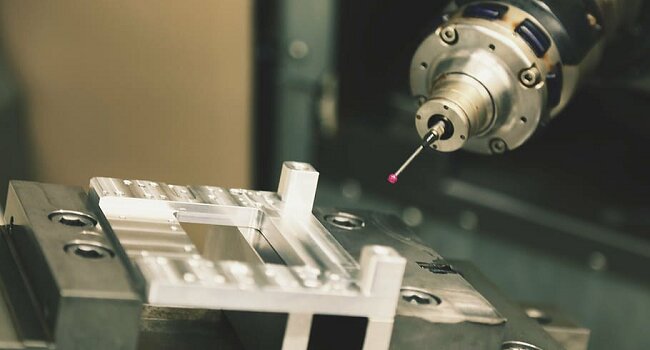

Before we delve into how CNC machines are revolutionising the construction industry, it’s crucial to understand what a CNC machine is. CNC, an acronym for Computer Numerical Control, refers to a method of automating control of machine tools through the use of software embedded in a microcomputer attached to the tool. The industries that utilize CNC machining are predominantly involving complex cuts, involving complex cuts, like drilling, milling, lathing, grinding, waterjet cutting and even 3D printing.

The intricacy of CNC machines is not confined to their physical aspects, but it extends to their functions and features as well. These tools can be programmed to perform precise, repetitive motions, a characteristic that sets them apart in the construction sector.

The Impact of CNC Machines on the Construction Industry

Now, let’s delve into how these machines have brought about significant changes in the construction industry.

CNC machines have instilled unprecedented precision and efficiency in the industry, marking a new era in construction. Their advanced technology enables builders to work with high accuracy, mitigating the risk of human error, which can lead to costly reworks. Additionally, with automation at the forefront, there’s a significant reduction in waste materials.

The use of CNC machines in construction also leads to a safer work environment. Their programming eliminates the need for workers to engage directly with heavy machinery, reducing the risk of workplace injuries.

Furthermore, the use of CNC machines brings about significant time savings. Traditional construction processes often involve lengthy timelines due to the manual aspect of the work. However, with the introduction of CNC machines, a considerable portion of the work is automated, reducing construction time dramatically.

Key Advantages of CNC Machines in Construction

In light of the above, let’s delve into the key benefits offered by CNC machines:

Accuracy and Precision: The pre-programmed software ensures that the cuts are exact, which is particularly important in construction where accuracy can make or break a project.

Efficiency and Speed: Automated tools can complete tasks much faster than manual labor, leading to faster project completion.

Safety: The automation of tasks reduces the need for manual handling of heavy machinery, thereby minimizing the risk of workplace accidents.

Cost Savings: The increased efficiency and reduced waste contribute to substantial cost savings in the long run.

Future of Construction: CNC Machines

The potential of CNC machines in the construction industry is enormous. It is expected that their influence will grow even more in the future, possibly paving the way for fully automated construction sites.

Recent research shows that construction companies are increasingly adopting CNC machines to stay competitive in the industry. The trend points to a future where manual labor is minimized, and automated machines, driven by digital technology, rule the construction sites. This not only will optimize the entire construction process but also will ensure safety and sustainability.

Moreover, with the advent of AI and machine learning, the capabilities of CNC machines are likely to expand. They might be programmed to make decisions, correct errors, and even adapt to unforeseen circumstances in construction projects.

Adopting CNC Machines: A Step-by-step Guide

For construction companies looking to join the revolution and embrace the benefits that CNC machines bring, it’s important to know how to get started. Here is a comprehensive guide to help navigate the process of adopting CNC technology.

Evaluate Your Needs

Start by assessing the needs of your construction projects. Consider the scale of the work, the complexity of tasks, and the accuracy required. This will help you identify the specific functionalities you will need in a CNC machine.

Choose the Right Machine

There are various types of CNC machines available, each suited to different tasks. For instance, a CNC waterjet machine is best for tasks requiring high precision cutting, while a CNC lathe would be ideal for producing cylindrical parts. It’s crucial to select a machine that matches your construction needs.

Invest in Training

Using CNC machines requires a certain level of technical knowledge. Therefore, investing in proper training for your workforce is crucial. This includes not only operating the machine but also programming it to suit the specific tasks.

Implement Safety Measures

Although CNC machines enhance workplace safety by reducing the need for manual labor, they can still pose hazards if not used correctly. Ensure all safety guidelines are followed and protective gear is used by those handling the machines.

Maintain Your CNC Machines

Regular maintenance of your CNC machines ensures their longevity and performance. This includes cleaning, lubrication, and routine checks for any potential issues.

CNC Machines and Sustainability in Construction

In addition to enhancing efficiency and accuracy, CNC machines play a pivotal role in making the construction industry more sustainable. They achieve this in a variety of ways:

Reduction in Material Waste

CNC machines, with their precision cutting abilities, significantly reduce the amount of waste produced during construction. This not only results in cost savings but also lessens the environmental impact of construction projects.

Energy Efficiency

CNC machines are often more energy-efficient than traditional construction equipment. By automating processes, they reduce the time and energy spent on manual labor.

Sustainable Materials

CNC machines have the capability to work with a range of materials, including sustainable options like recycled plastics and bio-based materials. This opens up new possibilities for eco-friendly construction.

Conclusion

Embracing the Future with CNC Machines

In conclusion, the advent of CNC machines represents a significant leap forward for the construction industry. They offer numerous benefits, from improved accuracy and efficiency to enhanced safety and sustainability. By embracing this technology, construction companies can stay competitive in a rapidly evolving industry while also contributing to a more sustainable future.

The CNC revolution is well underway, and those who adopt these machines stand to reap substantial rewards. As CNC machines continue to evolve, they promise to bring even more exciting possibilities to the world of construction. In the face of such potential, the future of construction is indeed looking brighter than ever.