Carbon Neutral Construction Sites: Strategies for Achieving Net-Zero Operations

The construction industry stands at a critical juncture in the global climate crisis, responsible for approximately 39% of global energy-related carbon emissions while facing increasing pressure to demonstrate environmental leadership through carbon neutral construction sites. This transformative approach to construction operations represents more than regulatory compliance—it embodies a fundamental shift toward sustainable practices that eliminate greenhouse gas emissions throughout the construction process. As governments worldwide mandate net-zero targets by 2050, construction companies must develop comprehensive strategies that achieve carbon neutrality while maintaining project quality, schedule adherence, and cost competitiveness.

Understanding Carbon Neutral Construction Operations

Carbon neutral construction operations encompass comprehensive approaches to eliminating net greenhouse gas emissions from all construction activities including equipment operation, material transportation, energy consumption, and waste management. Carbon neutral construction sites achieve this goal through a combination of emission reduction strategies, renewable energy adoption, and carbon offsetting mechanisms that result in zero net carbon footprint throughout project duration.

The scope of carbon neutral construction extends beyond operational emissions to include embodied carbon from construction materials, transportation impacts, and waste disposal activities. This holistic approach addresses Scope 1 emissions from direct fuel combustion, Scope 2 emissions from purchased electricity, and Scope 3 emissions from supply chain activities, creating comprehensive carbon accounting systems that capture all emission sources.

The built environment’s massive carbon footprint creates both challenges and opportunities for the construction industry. Buildings and construction activities account for nearly 40% of global carbon emissions, with construction operations contributing approximately 11% of these emissions through equipment operation, material production, and transportation activities. This substantial impact provides significant potential for emission reductions through strategic interventions and operational improvements.

Industry leaders demonstrate that carbon neutral construction is achievable through systematic approaches to emission identification, reduction strategies, and offsetting mechanisms. Pioneering projects report successful carbon neutrality achievement while maintaining competitive project delivery timelines and budgets, proving that environmental responsibility and commercial viability can coexist effectively.

Comprehensive Carbon Footprint Assessment and Baseline Establishment

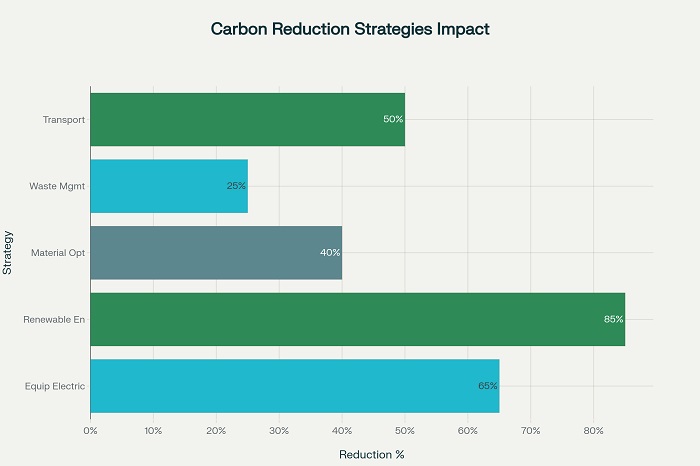

Achieving carbon neutral construction sites requires detailed understanding of all emission sources through comprehensive carbon footprint assessments that establish accurate baselines for reduction strategies. This systematic approach enables construction teams to identify major emission sources, prioritize reduction opportunities, and track progress toward carbon neutrality goals.

Construction carbon assessments encompass direct emissions from equipment operation including diesel fuel consumption by excavators, bulldozers, cranes, and generators that represent the largest single source of construction site emissions. These direct emissions typically account for 60-70% of total construction site carbon footprint, making equipment electrification and fuel efficiency improvements primary targets for emission reduction strategies.

Material transportation represents another significant emission source, with heavy-duty trucks and delivery vehicles contributing substantial carbon footprints through diesel fuel consumption and logistics inefficiencies. Construction projects report transportation-related emissions ranging from 15-25% of total project carbon footprint, depending on material sources, project location, and logistics optimization strategies.

Electricity consumption for site lighting, temporary buildings, and electric equipment contributes additional emissions depending on grid carbon intensity and renewable energy utilization. Construction sites increasingly implementing renewable energy systems report electricity-related emission reductions of 80-90% through solar panel installations and battery storage systems.

Waste management activities including disposal transportation, landfill methane emissions, and missed recycling opportunities contribute smaller but measurable carbon impacts. Comprehensive waste reduction and recycling programs typically achieve 20-30% reductions in waste-related emissions while supporting circular economy principles.

Equipment Electrification and Clean Energy Transition

The transition from diesel-powered construction equipment to electric alternatives represents the most impactful strategy for achieving carbon neutral construction sites. Electric construction equipment eliminates direct emissions while providing superior performance characteristics including instant torque, reduced noise pollution, and lower maintenance requirements compared to traditional diesel machinery.

Electric excavators, bulldozers, and material handlers demonstrate comparable performance to diesel counterparts while eliminating direct carbon emissions and reducing operational noise by up to 50%. Leading manufacturers report electric equipment adoption increasing 40% annually as battery technology improvements extend operating ranges and reduce charging times. Major construction projects implementing comprehensive equipment electrification achieve direct emission reductions exceeding 60%.

Construction site electrification requires robust charging infrastructure including high-capacity charging stations, electrical distribution systems, and energy management platforms that coordinate equipment charging with renewable energy availability. Solar-powered charging systems enable construction sites to achieve complete energy independence while eliminating grid electricity emissions.

Battery technology advancements enable electric construction equipment to operate full shifts without charging interruptions. Modern lithium-ion battery systems provide 8-12 hours of continuous operation while supporting rapid charging capabilities that restore full capacity within 2-3 hours. Advanced battery management systems optimize charging schedules to coincide with peak renewable energy generation periods.

Hybrid equipment solutions provide transitional pathways for companies unable to implement full electrification immediately. Hybrid excavators and dozers achieve 20-40% fuel consumption reductions while maintaining operational flexibility for projects lacking charging infrastructure. These hybrid systems enable gradual transition strategies that build organizational experience with electric equipment while delivering immediate emission reductions.

Renewable Energy Integration and Energy Independence

Implementing comprehensive renewable energy systems enables carbon neutral construction sites to achieve energy independence while eliminating emissions from grid electricity consumption. Solar photovoltaic installations, wind generation systems, and energy storage solutions provide reliable, emission-free power for all construction site activities including equipment charging, lighting, and temporary facilities.

Solar panel installations on construction sites typically generate 150-300 kWh per day per installed kW capacity, depending on geographic location and seasonal variations. Construction projects report solar system payback periods of 12-18 months through eliminated electricity costs and accelerated depreciation benefits. Temporary solar installations enable renewable energy utilization across multiple projects while maintaining equipment investment efficiency.

Battery energy storage systems enable construction sites to maintain operations during periods of limited renewable generation while optimizing energy utilization patterns. Advanced lithium-ion battery systems provide 4-8 hours of backup power while supporting peak shaving strategies that reduce grid electricity consumption during high-demand periods. Storage systems typically achieve 85-90% round-trip efficiency while providing grid stabilization services.

Wind generation systems provide complementary renewable energy production that often peaks during periods of limited solar generation. Small-scale wind turbines generate 50-200 kWh per day depending on wind conditions and turbine specifications. Combined solar-wind systems achieve higher capacity factors and improved energy security compared to single-source renewable installations.

Smart energy management systems optimize renewable energy utilization while coordinating equipment charging schedules, facility operations, and energy storage management. These systems achieve 15-25% improvements in renewable energy utilization efficiency while reducing overall energy consumption through demand response strategies and load optimization.

Sustainable Material Selection and Supply Chain Optimization

Material selection represents a crucial strategy for achieving carbon neutral construction sites through specification of low-carbon alternatives, recycled content materials, and locally sourced products that minimize transportation emissions. Strategic material choices can reduce project embodied carbon by 30-50% while supporting circular economy principles and regional economic development.

Low-carbon concrete alternatives including fly ash substitution, recycled aggregate utilization, and innovative cement chemistries reduce concrete-related emissions by 20-40% compared to traditional Portland cement formulations. These alternatives often provide superior durability characteristics while reducing material costs through waste material utilization and local sourcing opportunities.

Steel recycling and secondary steel utilization eliminate 70-80% of emissions compared to primary steel production while providing identical performance characteristics. Construction projects implementing comprehensive steel recycling programs achieve material cost reductions of 15-25% while significantly reducing project carbon footprints through material circularity.

Local material sourcing reduces transportation-related emissions while supporting regional economies and reducing material costs through eliminated shipping expenses. Projects implementing local sourcing strategies report transportation emission reductions of 40-60% while achieving material cost savings of 10-20% through reduced logistics complexity.

Timber and bio-based materials provide carbon storage benefits that contribute negative emissions to project carbon calculations. Sustainable forest products sequester atmospheric carbon while providing renewable alternatives to carbon-intensive materials like steel and concrete. Mass timber construction projects achieve 25-35% carbon footprint reductions compared to conventional steel and concrete construction.

Advanced Waste Management and Circular Economy Integration

Implementing comprehensive waste management strategies enables carbon neutral construction sites to achieve circular economy benefits while eliminating waste-related emissions through material recovery, recycling optimization, and waste-to-energy conversion. Advanced waste management typically reduces overall project environmental impact by 20-30% while generating cost savings through reduced disposal expenses.

Construction waste sorting and material recovery systems enable reuse of concrete, steel, wood, and other materials for current projects or future applications. On-site material processing equipment including concrete crushers and wood chippers convert construction waste into useful materials while eliminating transportation emissions associated with waste disposal. Material recovery typically achieves 60-80% waste diversion rates while reducing disposal costs.

Prefabrication and modular construction techniques reduce material waste by 15-25% through precise material utilization and controlled manufacturing environments. Off-site fabrication enables comprehensive material recovery and recycling while reducing on-site waste generation through improved quality control and reduced rework requirements.

Waste-to-energy systems convert organic construction waste into renewable energy through anaerobic digestion or biomass combustion processes. These systems eliminate methane emissions from organic waste decomposition while generating renewable energy for construction site operations. Waste-to-energy conversion typically processes 20-30% of construction waste volume while generating 10-15% of site energy requirements.

Packaging reduction strategies including reusable containers, bulk material delivery, and supplier coordination eliminate significant waste streams while reducing material costs. Projects implementing comprehensive packaging reduction achieve 30-40% reductions in packaging waste while reducing material costs through supplier collaboration and delivery optimization.

Carbon Offset Integration and Nature-Based Solutions

Carbon offset programs provide essential mechanisms for achieving complete carbon neutrality by compensating for remaining emissions through verified carbon reduction or sequestration projects. Carbon neutral construction sites implement high-quality offset programs that deliver measurable environmental benefits while supporting sustainable development objectives.

Reforestation and afforestation projects provide long-term carbon sequestration while delivering biodiversity benefits and ecosystem services. Construction companies investing in forest carbon projects typically purchase offsets at $15-30 per ton of CO2 equivalent while supporting conservation efforts and rural economic development. Mature forest projects sequester 10-20 tons CO2 per hectare annually over 30-50 year project lifespans.

Renewable energy development projects eliminate fossil fuel emissions while accelerating clean energy transition in developing regions. Construction companies supporting wind and solar projects through carbon credit purchases contribute to global decarbonization while offsetting project emissions at competitive prices. Renewable energy credits typically cost $5-15 per ton CO2 equivalent while delivering permanent emission reductions.

Direct air capture technologies provide emerging opportunities for permanent carbon removal that delivers verifiable, additional emission reductions. While currently expensive at $200-600 per ton CO2, direct air capture prices decline rapidly as technology scales and deployment increases. Early adopters gain experience with permanent carbon removal while supporting technology development.

Regenerative agriculture projects improve soil carbon sequestration while supporting sustainable farming practices and rural economic development. Agricultural carbon credits typically cost $10-25 per ton CO2 while delivering additional benefits including improved water quality, biodiversity enhancement, and farmer income support. Soil carbon projects achieve 1-3 tons CO2 sequestration per hectare annually.

Technology Integration for Emission Monitoring and Optimization

Advanced monitoring technologies enable carbon neutral construction sites to track emissions in real-time while optimizing operations for maximum carbon efficiency. Internet of Things (IoT) sensors, emissions monitoring equipment, and data analytics platforms provide comprehensive visibility into carbon performance while supporting continuous improvement initiatives.

Emissions monitoring systems track fuel consumption, electricity usage, and equipment efficiency in real-time while providing immediate feedback for operational optimization. These systems identify inefficient equipment operation, unnecessary fuel consumption, and optimization opportunities that typically reduce emissions by 10-15% through behavioral modifications and operational improvements.

Artificial intelligence platforms analyze operational data to identify patterns and recommend optimization strategies that reduce emissions while maintaining productivity. AI-driven optimization typically achieves 15-25% efficiency improvements through predictive maintenance, route optimization, and resource allocation strategies. Machine learning algorithms continuously improve recommendation accuracy through operational experience and performance feedback.

Digital twin technologies enable construction teams to model and optimize carbon performance throughout project execution. Virtual construction models simulate different scenarios, evaluate emission reduction strategies, and optimize resource allocation for minimum carbon impact. Digital twin optimization typically reduces project carbon footprint by 20-30% through improved planning and execution strategies.

Blockchain platforms provide transparent, verifiable carbon accounting that supports regulatory compliance and stakeholder reporting requirements. Immutable carbon records enable accurate emission tracking while supporting carbon credit generation and trading activities. Blockchain-based carbon accounting reduces administrative overhead while improving data accuracy and stakeholder confidence.

Economic Analysis and Return on Investment

Implementing carbon neutral construction sites requires substantial upfront investments that generate long-term economic returns through operational savings, competitive advantages, and regulatory compliance benefits. Comprehensive economic analysis demonstrates that carbon neutrality investments typically achieve positive returns within 18-36 months while delivering sustained competitive advantages.

Equipment electrification investments typically range from $100,000-500,000 per major piece of equipment while generating fuel savings of $50,000-150,000 annually through eliminated diesel consumption. Electric equipment maintenance costs are typically 40-60% lower than diesel counterparts through reduced component complexity and eliminated fluid changes. Total cost of ownership analysis typically favors electric equipment within 24-36 months.

Renewable energy system investments typically cost $2,000-4,000 per installed kW while generating electricity at $0.05-0.08 per kWh compared to grid electricity costs of $0.10-0.25 per kWh. Solar system payback periods typically range from 12-24 months while providing 20-25 years of operational benefits. Energy storage systems provide additional value through demand charge reduction and grid service revenues.

Carbon credit costs for offset programs typically range from $10-50 per ton CO2 equivalent depending on project type and verification standards. High-quality offset programs deliver additional benefits including biodiversity conservation, community development, and ecosystem services that provide value beyond carbon neutrality. Offset investments typically represent 2-5% of total project costs while enabling complete carbon neutrality.

Competitive advantages from carbon neutrality include preferential bidding opportunities, premium pricing capabilities, and enhanced client relationships that generate 10-20% revenue premiums for sustainable construction services. Many clients now require carbon neutral construction, creating market differentiation opportunities for early adopters while eliminating competition from companies lacking sustainability capabilities.

Regulatory Compliance and Certification Programs

Carbon neutral construction sites increasingly require compliance with evolving regulations while pursuing third-party certifications that validate sustainability achievements. Regulatory frameworks including carbon pricing, emission reporting requirements, and procurement preferences create both compliance obligations and market opportunities for carbon neutral construction companies.

Government carbon pricing mechanisms including carbon taxes and cap-and-trade programs create direct financial incentives for emission reduction while penalizing high-carbon construction practices. Carbon prices typically range from $10-100 per ton CO2 equivalent depending on jurisdiction and policy design. Companies achieving carbon neutrality avoid carbon costs while potentially generating revenue through carbon credit sales.

Emission reporting requirements including Scope 1, 2, and 3 reporting mandates require comprehensive carbon accounting systems that track all emission sources throughout project execution. Regulatory reporting typically requires third-party verification while supporting transparency initiatives that enhance stakeholder confidence and competitive positioning.

Green building certification programs including LEED, BREEAM, and Green Star increasingly require construction carbon neutrality for highest certification levels. Certified projects typically achieve 10-15% premium pricing while accessing preferential financing and insurance terms. Certification programs provide standardized frameworks for carbon neutral achievement while supporting continuous improvement initiatives.

Government procurement preferences for carbon neutral construction create substantial market opportunities for qualified contractors while eliminating competition from high-carbon alternatives. Public sector projects increasingly require carbon neutrality demonstration through verified emission reduction and offsetting programs. These procurement requirements typically represent 20-30% of total construction market value in developed economies.

Future Evolution and Emerging Technologies

The trajectory of carbon neutral construction technology development points toward even more sophisticated emission reduction capabilities as emerging technologies mature and deployment costs decline. Advanced technologies including hydrogen fuel cells, synthetic fuels, and carbon capture systems promise to further enhance carbon neutrality achievement while reducing implementation costs.

Hydrogen fuel cell technology provides emission-free alternatives for heavy construction equipment while offering faster refueling and extended operating ranges compared to battery electric systems. Fuel cell excavators and dozers demonstrate comparable performance to diesel equipment while eliminating direct emissions and reducing noise pollution. Hydrogen infrastructure development enables comprehensive equipment conversion while supporting multiple industrial applications.

Synthetic fuel production from renewable electricity and atmospheric carbon dioxide provides carbon neutral alternatives for equipment unable to electrify immediately. E-fuels enable continued use of existing equipment while achieving carbon neutrality through renewable energy-powered fuel synthesis. Synthetic fuel costs decline rapidly as production scales while providing drop-in replacements for diesel fuel.

Carbon capture and utilization technologies enable construction sites to capture atmospheric carbon dioxide for beneficial use in concrete production and other applications. Direct air capture systems integrated with concrete plants produce carbon-negative building materials while eliminating atmospheric carbon dioxide. These technologies transform construction sites from carbon sources into carbon sinks.

Advanced materials including bio-based composites, recycled content products, and self-healing materials reduce embodied carbon while improving performance characteristics. Next-generation materials often provide carbon storage benefits while delivering superior durability and functionality compared to conventional alternatives.

Conclusion

Carbon neutral construction sites represent an essential evolution in construction industry practices that addresses climate change imperatives while delivering measurable economic and competitive benefits. The comprehensive strategies outlined—including equipment electrification, renewable energy integration, sustainable material selection, and advanced monitoring systems—provide proven pathways for achieving complete carbon neutrality while maintaining project quality and commercial viability.

The construction industry’s transition to carbon neutrality accelerates as regulatory requirements intensify and market demand for sustainable construction services grows. Early adopters demonstrate that carbon neutral construction not only addresses environmental responsibilities but also creates competitive advantages, cost savings, and operational improvements that enhance long-term business success.

The future of construction lies in the intelligent integration of emission reduction strategies, renewable energy systems, and advanced technologies that transform construction sites from carbon sources into carbon neutral or even carbon negative operations. Organizations that embrace comprehensive carbon neutral strategies today will lead the industry’s evolution toward sustainable construction practices while setting new standards for environmental stewardship and operational excellence.