Augmented Reality in Construction Equipment Operation: Enhancing Operator Guidance and Training

The construction industry is witnessing a revolutionary transformation as augmented reality (AR) technology redefines how heavy equipment operators learn, work, and interact with complex machinery. This cutting-edge technology overlays digital information onto the physical world, creating AR operator guidance systems that enhance safety, productivity, and operational precision.

With the global AR/VR market experiencing explosive growth at a compound annual growth rate of 77% from 2019 to 2024, construction companies are increasingly recognizing AR’s potential to address critical challenges in operator training, equipment operation, and workplace safety.

Understanding Augmented Reality in Construction Equipment Context

Augmented reality technology in construction equipment operation represents a paradigm shift from traditional training methods and operational interfaces to immersive, interactive systems that provide real-time information and guidance. Unlike virtual reality, which creates entirely artificial environments, AR enhances the real world by overlaying digital elements such as instructions, safety warnings, performance metrics, and operational data directly onto the operator’s field of view.

Modern AR operator guidance systems integrate sophisticated hardware including high-definition displays, sensors, cameras, and processing units with advanced software platforms that deliver contextual information precisely when and where operators need it. These systems transform traditional equipment cabins into intelligent workspaces where operators receive continuous guidance, performance feedback, and safety alerts without diverting attention from their primary tasks.

The construction equipment manufacturing sector is investing heavily in AR integration, with companies like Caterpillar, Komatsu, and John Deere developing comprehensive AR solutions for their machinery. These systems provide operators with real-time access to equipment manuals, maintenance procedures, operational best practices, and troubleshooting guidance directly through AR interfaces mounted within equipment cabins or through wearable devices.

The sophistication of these systems extends beyond simple information display to include predictive analytics, machine learning algorithms, and artificial intelligence capabilities that adapt to individual operator behaviors and preferences. Advanced AR platforms can recognize operator skill levels and customize information delivery, accordingly, providing novice operators with detailed step-by-step guidance while offering experienced operators condensed, relevant data.

Revolutionizing Operator Training Through Immersive AR Experiences

Traditional construction equipment training approaches rely heavily on classroom instruction followed by supervised hands-on practice with actual machinery. While effective, these methods present significant challenges including equipment availability, safety risks, training costs, and limited scenario variety. AR operator guidance systems address these limitations by creating immersive training environments that combine theoretical knowledge with practical application in safe, controlled settings.

AR training systems enable operators to practice complex procedures using virtual equipment overlays on physical training platforms or through completely digital simulations accessed via AR headsets. Trainees can learn to operate excavators, cranes, bulldozers, and other heavy machinery without the risks associated with actual equipment operation. This approach significantly reduces training costs while providing unlimited practice opportunities for mastering challenging scenarios.

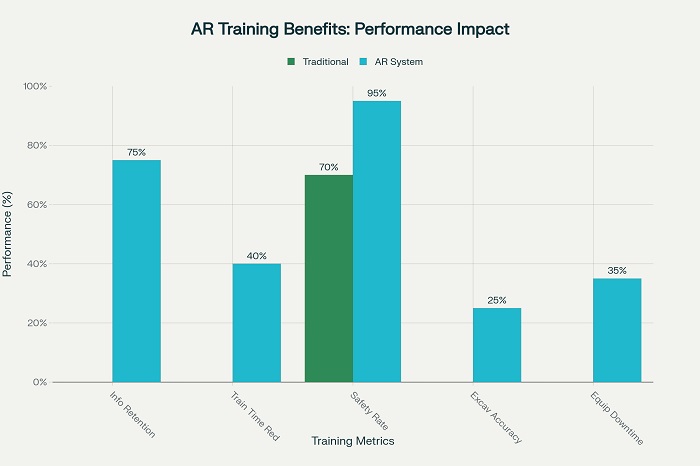

The effectiveness of AR training surpasses traditional methods in several key areas. Studies demonstrate that trainees using AR-based instruction retain information 75% more effectively than those using conventional training approaches. The immersive, interactive nature of AR training engages multiple learning modalities simultaneously, creating stronger neural pathways and improved skill retention.

Caterpillar’s AR training initiative exemplifies the technology’s transformative potential. The company developed comprehensive AR training modules that allow operators to practice equipment operation in realistic virtual environments. Trainees can experience various weather conditions, terrain types, and operational challenges without physical risks. The system tracks performance metrics, identifies areas for improvement, and provides personalized feedback to accelerate skill development.

One construction company reported reducing operator training time by 40% while simultaneously improving safety compliance rates to 95% after implementing comprehensive AR training programs. The system’s ability to simulate dangerous scenarios safely enables trainees to practice emergency procedures and develop appropriate responses without exposing them to actual hazards.

Enhancing Real-Time Operational Guidance and Decision Support

The integration of AR technology into construction equipment operation extends far beyond training applications to encompass comprehensive operational support that transforms how operators interact with machinery during actual work activities. AR operator guidance systems provide continuous, contextual information that enhances decision-making, improves operational efficiency, and reduces the likelihood of errors or accidents.

Modern AR systems display critical operational information including equipment performance metrics, fuel consumption rates, hydraulic system pressures, and component temperatures directly within the operator’s field of view. This real-time data enables operators to make informed decisions about equipment operation, workload management, and maintenance requirements without interrupting their workflow to consult separate displays or documentation.

Navigation and positioning capabilities represent another significant advancement in AR-enabled equipment operation. GPS integration with AR interfaces provides operators with precise location information, optimal path guidance, and proximity warnings when working near obstacles or other equipment. These systems can display planned excavation boundaries, grade requirements, and material placement locations directly onto the work area, ensuring accurate execution of complex tasks.

Maintenance and troubleshooting support through AR systems significantly reduces equipment downtime and repair costs. When equipment malfunctions occur, AR interfaces can display diagnostic information, troubleshooting procedures, and repair instructions directly relevant to the specific issue. Operators can access detailed component information, replacement procedures, and safety protocols without consulting separate manuals or waiting for technical support.

A major infrastructure project reported 25% improvement in excavation accuracy and 30% reduction in rework requirements after implementing AR guidance systems on their equipment fleet. The technology’s ability to provide precise visual guidance for complex grading and excavation tasks eliminated many common errors while improving overall project quality.

Advancing Safety Protocols Through AR-Enhanced Awareness

Safety considerations drive much of the innovation in AR applications for construction equipment operation. The construction industry’s challenging safety record, with equipment-related incidents accounting for significant percentages of workplace injuries, creates urgent needs for technological solutions that enhance operator awareness and decision-making capabilities.

AR operator guidance systems address safety challenges through multiple complementary approaches including proximity detection, hazard identification, and emergency response guidance. Advanced systems integrate with equipment sensors and site-wide monitoring networks to provide operators with comprehensive situational awareness that extends far beyond their natural field of view.

Collision avoidance capabilities represent one of the most impactful safety applications of AR technology. These systems use radar, lidar, and camera sensors to detect nearby personnel, vehicles, and obstacles, displaying warning information directly within the operator’s visual field. When potential collision risks are identified, the AR system provides immediate visual and auditory alerts while highlighting the hazard’s location and severity.

Blind spot monitoring through AR interfaces eliminates many visibility-related safety risks associated with heavy equipment operation. Cameras positioned around equipment feed real-time imagery to AR displays, creating virtual “windows” that allow operators to see areas traditionally obscured by equipment structure. This enhanced visibility significantly reduces the risk of accidents involving personnel or equipment operating in close proximity.

Environmental hazard detection through AR systems provides operators with continuous monitoring of conditions that could affect safe operation. Air quality sensors, weather monitoring systems, and ground stability assessments feed information to AR interfaces, enabling operators to make informed decisions about continuing operations or implementing additional safety measures.

One metropolitan construction project achieved zero equipment-related injuries during a two-year period by implementing comprehensive AR safety systems across their equipment fleet. The systems integrated proximity sensors, collision avoidance technology, and real-time hazard monitoring to create multiple layers of safety protection for operators and nearby personnel.

Optimizing Equipment Performance Through AR-Enabled Analytics

The integration of advanced analytics with AR interfaces creates powerful optimization capabilities that enhance equipment performance, reduce operating costs, and extend machinery lifespans. AR operator guidance systems process vast amounts of operational data to identify efficiency opportunities, predict maintenance requirements, and optimize equipment utilization patterns.

Fuel efficiency optimization through AR systems provides operators with real-time guidance on operating techniques that minimize fuel consumption while maintaining productivity. The systems analyze factors including engine load, hydraulic system pressure, and operating speed to recommend adjustments that improve fuel economy. Operators receive immediate feedback on their operating techniques, enabling continuous improvement in efficiency practices.

Performance benchmarking capabilities enable operators to compare their productivity metrics against established standards and best practices. AR interfaces display productivity targets, current performance levels, and recommended improvements in easily understood visual formats. This gamification approach to performance management motivates operators to continuously improve their skills while maintaining quality standards.

Predictive maintenance integration with AR systems enables operators to identify potential equipment issues before they result in failures or downtime. Machine learning algorithms analyze operational data patterns to predict component wear, system degradation, and maintenance requirements. AR interfaces alert operators to emerging issues and provide guidance on preventive measures or maintenance scheduling.

Load optimization through AR guidance helps operators maximize equipment productivity while avoiding overloading that could cause damage or safety risks. The systems calculate optimal load sizes based on material properties, equipment capabilities, and operational conditions, displaying recommendations directly within the operator’s field of view.

A construction equipment rental company reported 20% improvement in fuel efficiency and 35% reduction in unscheduled maintenance events after implementing AR-enabled performance optimization systems across their fleet. The technology’s ability to provide continuous guidance and feedback enabled operators to develop more efficient working practices while extending equipment lifespans.

Integration with Building Information Modeling and Project Management

The convergence of AR technology with Building Information Modeling (BIM) and comprehensive project management systems creates unprecedented opportunities for precision and coordination in construction equipment operation. AR operator guidance systems that integrate with project databases can provide operators with detailed information about planned activities, design specifications, and quality requirements directly relevant to their current tasks.

BIM integration enables AR systems to display three-dimensional design models overlaid onto physical work areas, providing operators with precise guidance for excavation depths, grade requirements, and material placement specifications. This integration eliminates the need for traditional survey stakes and grade markers while ensuring accurate execution of complex design requirements.

Project scheduling integration coordinates equipment operations with overall project timelines, providing operators with information about upcoming activities, resource requirements, and completion deadlines. AR interfaces can display task priorities, sequence requirements, and coordination needs that help operators plan their work activities effectively.

Quality control integration through AR systems enables operators to verify their work against project specifications in real time. The systems can highlight areas where work meets or exceeds quality standards while identifying locations requiring additional attention or rework. This immediate feedback capability significantly improves first-time quality rates while reducing inspection requirements.

Material management integration provides operators with information about material sources, placement requirements, and quantity specifications relevant to their current activities. AR systems can guide operators to appropriate material stockpiles, display loading requirements, and track material usage against project budgets and schedules.

Overcoming Implementation Challenges and Maximizing ROI

The successful deployment of AR operator guidance systems requires strategic approaches to address technical, financial, and organizational challenges that can impact implementation effectiveness. Companies must carefully evaluate their specific needs, existing infrastructure, and organizational readiness to ensure successful AR integration.

Technology infrastructure requirements include robust communication networks, adequate processing capabilities, and reliable power systems that can support AR operations in challenging construction environments. Many construction sites lack the high-speed connectivity necessary for cloud-based AR applications, requiring investment in private networks or edge computing solutions.

Operator acceptance and training represent critical success factors for AR implementation. Construction equipment operators often have extensive experience with traditional operating methods and may resist technological changes that alter familiar workflows. Comprehensive change management programs that emphasize benefits, provide adequate training, and address operator concerns are essential for successful adoption.

Cost-benefit analysis considerations include initial hardware and software investments, ongoing maintenance costs, training expenses, and expected returns through improved productivity, reduced accidents, and enhanced equipment utilization. While AR systems require substantial upfront investments, many organizations achieve payback periods of 12-24 months through operational improvements and cost savings.

Integration complexity can pose challenges when connecting AR systems with existing equipment, project management platforms, and communication networks. Successful implementations require careful planning, system compatibility assessment, and often custom integration development to achieve seamless operation across diverse technology ecosystems.

Future Evolution and Emerging Capabilities

The development trajectory of AR technology in construction equipment operation points toward even more sophisticated capabilities as underlying technologies continue advancing and integration with other emerging technologies creates new possibilities for equipment operation and management.

Artificial intelligence integration with AR systems will enable more sophisticated decision support, automated guidance, and predictive capabilities. AI algorithms will analyze operational patterns, environmental conditions, and project requirements to provide increasingly intelligent recommendations for equipment operation and optimization.

5G network deployment will enable more sophisticated real-time communications between equipment, operators, and central management systems. Ultra-low latency communications will support advanced applications including remote operation, autonomous coordination, and real-time optimization across equipment fleets.

Autonomous equipment coordination represents an emerging frontier where AR systems will interface with autonomous construction machinery to create comprehensive automation ecosystems. Human operators will transition from direct equipment control to supervisory roles, using AR interfaces to monitor and coordinate multiple autonomous systems simultaneously.

Advanced sensor integration will expand AR systems’ environmental awareness capabilities, incorporating technologies such as thermal imaging, gas detection, and structural monitoring to provide operators with comprehensive situational awareness and safety protection.

Conclusion

AR operator guidance systems represent a transformative advancement in construction equipment operation that addresses the industry’s most pressing challenges through enhanced training, improved safety, and optimized performance. The technology’s ability to provide immersive training experiences, real-time operational guidance, and comprehensive safety support creates unprecedented opportunities for improving construction operations while protecting workers and equipment.

The construction industry’s adoption of AR technology is accelerating as organizations recognize the compelling benefits and rapid return on investment achievable through comprehensive implementation. Early adopters demonstrate that AR-enabled equipment operation not only improves productivity and safety but also enhances operator satisfaction and retention in an industry facing significant workforce challenges.

The future of construction equipment operation lies in the intelligent integration of AR technology that combines human expertise with digital intelligence to create more efficient, safer, and more productive construction operations. Organizations that embrace comprehensive AR operator guidance systems today will lead the industry’s evolution toward intelligent, connected equipment ecosystems that redefine the possibilities for construction project delivery and operational excellence.