Digital Twin Technology: Bridging Virtual Design and Physical Construction Reality

The construction industry stands at the convergence of virtual innovation and physical reality, where digital twin technology creates unprecedented opportunities for bridging the gap between conceptual design and tangible construction outcomes. This transformative approach to virtual design and physical construction integration represents a paradigm shift from static blueprints to dynamic, intelligent models that evolve throughout a project’s entire lifecycle.

Understanding Digital Twin Technology in Construction Context

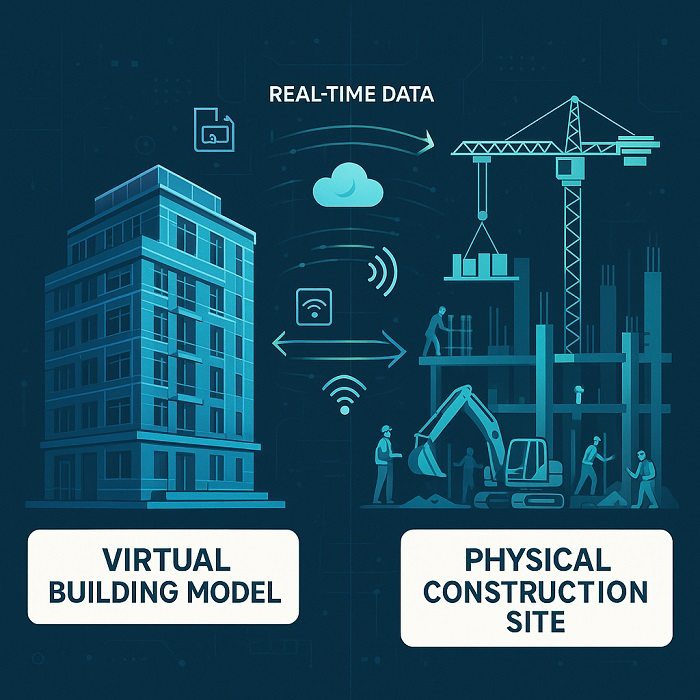

Digital twin technology transcends traditional Building Information Modeling (BIM) by creating living, breathing virtual replicas of physical construction projects. Unlike static 3D models, digital twins continuously ingest real-time data from Internet of Things (IoT) sensors, construction equipment, and environmental monitoring systems to maintain perfect synchronization between virtual representations and physical reality.

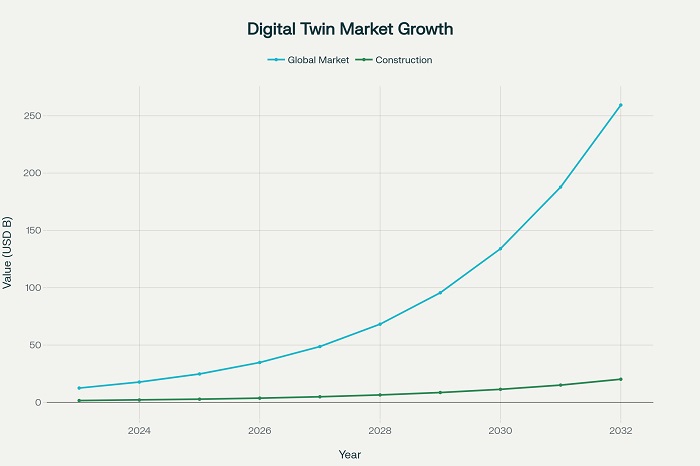

The global digital twin market demonstrates explosive growth, expanding from USD 17.73 billion in 2024 to a projected USD 259.32 billion by 2032, exhibiting a compound annual growth rate of 40.1%

The construction sector specifically shows remarkable adoption rates, with the digital twin for buildings market valued at USD 1.6 billion in 2023 and projected to reach USD 20.2 billion by 2032 at a CAGR of 32.6%

This technology fundamentally transforms how construction professionals approach project planning, execution, and facility management by providing unprecedented visibility into every aspect of the construction process. Teams can simulate construction sequences, predict potential issues, and optimize resource allocation with accuracy levels previously impossible through traditional planning methods.

Creating Intelligent Virtual Representations

The foundation of effective digital twin implementation rests on sophisticated data integration capabilities that combine design specifications, real-time sensor feeds, and construction progress information into comprehensive virtual models. These models serve as central nervous systems for construction projects, processing continuous streams of information to maintain accurate representations of physical assets.

Construction digital twins leverage advanced technologies including machine learning algorithms, artificial intelligence, and predictive analytics to transform raw data into actionable insights. Temperature sensors embedded in concrete report curing progress, while GPS tracking on equipment provides precise location and utilization data. Structural monitoring systems detect settlement patterns, load distributions, and environmental impacts that influence long-term building performance.

The integration of drone-captured imagery and laser scanning technology enables digital twins to verify construction progress against planned specifications with millimeter-level accuracy. This precision allows project managers to identify deviations immediately, preventing minor discrepancies from becoming major quality issues or costly rework scenarios.

One notable implementation at a major hospital construction project demonstrated the power of comprehensive digital twin integration. The system identified a critical MEP clash that would have cost three weeks and $200,000 to resolve during construction. By catching this conflict during the virtual design phase, the project team achieved significant cost savings while maintaining schedule adherence.

Enhancing Design Validation Through Virtual Simulation

Virtual design and physical construction convergence enables sophisticated simulation capabilities that allow architects and engineers to test design concepts under various real-world conditions before breaking ground. These simulations encompass structural loads, environmental factors, occupancy patterns, and system performance scenarios that would be impossible or prohibitively expensive to test physically.

Digital twin platforms facilitate comprehensive clash detection and resolution during the design phase, identifying conflicts between architectural, structural, mechanical, electrical, and plumbing systems. Advanced algorithms analyze spatial relationships, identify interferences, and recommend optimization strategies that improve constructability while maintaining design intent.

Environmental simulation capabilities within digital twin frameworks enable design teams to optimize building performance for specific site conditions. Solar analysis, wind flow patterns, thermal performance, and energy efficiency calculations provide detailed insights that inform design decisions and support sustainable construction practices. These simulations often reveal opportunities for 20-25% improvements in energy efficiency through optimized building orientation, material selection, and system integration.

The integration of occupancy modeling with digital twin technology allows designers to simulate human behavior patterns and their impact on building systems. This capability proves particularly valuable for complex structures like hospitals, airports, and educational facilities where occupancy patterns significantly influence operational efficiency and user experience.

Optimizing Construction Execution Through Real-Time Monitoring

The transition from virtual design to physical construction becomes seamless through digital twin technology’s real-time monitoring capabilities. Construction teams gain unprecedented visibility into project progress, resource utilization, and quality control processes that enable proactive management and immediate problem resolution.

IoT sensors deployed throughout construction sites feed continuous data streams into digital twin platforms, providing instant updates on material deliveries, equipment performance, workforce productivity, and environmental conditions. This real-time visibility enables construction managers to identify bottlenecks, optimize workflows, and maintain project momentum through data-driven decision-making.

Quality control processes benefit significantly from digital twin integration through automated monitoring and verification systems. Concrete placement equipment communicates pour parameters directly to quality management systems, while compaction machinery reports soil density data in real time. This automated quality documentation ensures compliance with specifications while reducing manual inspection requirements.

A metropolitan infrastructure project demonstrated remarkable results through comprehensive digital twin implementation. Real-time progress monitoring enabled project managers to coordinate multiple construction activities with precision, resulting in 35% faster completion times compared to traditional project management approaches. The system automatically recalibrated project timelines when delays occurred, highlighting downstream impacts and enabling proactive mitigation strategies.

Enabling Predictive Maintenance and Lifecycle Optimization

The value of virtual design and physical construction integration extends far beyond project completion through predictive maintenance capabilities that optimize building performance throughout operational lifecycles. Digital twins continue evolving after construction, incorporating operational data to predict maintenance needs, optimize system performance, and support facility management decisions.

Predictive maintenance algorithms analyze equipment performance patterns, environmental conditions, and usage data to forecast maintenance requirements before failures occur. HVAC systems communicate operational parameters that enable predictive models to identify inefficiencies and recommend optimization strategies. Early adopters report 25% average maintenance cost reductions through digital twin-enabled predictive maintenance programs.

Energy efficiency optimization represents a significant operational benefit of digital twin technology. Building systems continuously communicate performance data that enables optimization algorithms to adjust operations for maximum efficiency. One commercial complex achieved RM 420,000 annual energy savings through digital twin-enabled system optimization that identified and corrected chiller inefficiencies based on real-time operational data.

The integration of artificial intelligence with digital twin platforms creates learning systems that continuously improve building performance through pattern recognition and predictive modeling. These systems identify optimization opportunities that human facility managers might overlook while providing recommended actions to achieve maximum efficiency and occupant comfort.

Facilitating Stakeholder Collaboration and Communication

Digital twin technology transforms stakeholder collaboration by providing shared, real-time visibility into all aspects of construction projects. Architects, engineers, contractors, and owners access identical information through collaborative platforms that eliminate version control issues and ensure everyone works with current project data.

Immersive visualization capabilities within digital twin platforms enable stakeholders to experience projects before construction completion. Virtual reality integration allows clients to walk through spaces, evaluate design decisions, and request modifications during phases when changes remain cost-effective. This capability significantly reduces change orders and client dissatisfaction while improving overall project outcomes.

The collaborative benefits extend to contractor coordination, where digital twin platforms facilitate seamless information sharing between multiple trades and specialty contractors. Real-time progress updates, material delivery schedules, and quality control data enable coordinated construction activities that minimize conflicts and optimize productivity.

Communication improvements through digital twin implementation often translate into measurable project benefits. Reduced coordination meetings, faster decision-making processes, and improved information accuracy contribute to overall project efficiency while enhancing stakeholder satisfaction and project outcomes.

Overcoming Implementation Challenges and Barriers

Despite clear benefits, digital twin adoption in construction faces several challenges that organizations must address strategically. Initial implementation costs can be substantial, particularly for organizations lacking existing digital infrastructure. However, return on investment typically occurs within 6-12 months through improved productivity, reduced rework, and enhanced operational efficiency.

Data integration complexity represents another significant challenge as construction projects involve multiple systems, vendors, and data formats. Establishing comprehensive data governance frameworks and standardized integration protocols ensures successful digital twin implementation while maintaining data quality and security standards.

Workforce development requirements accompany digital twin adoption as construction teams must develop new skills for managing and interpreting complex digital systems. Training programs focused on digital twin operation, data analysis, and system maintenance ensure teams can effectively leverage these advanced technologies.

Interoperability concerns arise when integrating equipment and systems from multiple manufacturers with different communication protocols. Industry standardization efforts, including open data standards and common communication protocols, address these challenges while enabling comprehensive digital twin implementations across diverse technology ecosystems.

Advanced Applications and Emerging Capabilities

The evolution of digital twin technology continues expanding possible applications within construction through integration with emerging technologies including artificial intelligence, blockchain, and quantum computing. These advanced capabilities promise even more sophisticated applications for virtual design and physical construction optimization.

Autonomous construction equipment integration with digital twin platforms enables coordinated robotic operations that execute complex construction tasks with minimal human intervention. Digital twins provide the spatial awareness and coordination capabilities necessary for safe, efficient autonomous operations while maintaining quality standards.

Supply chain optimization through digital twin integration enables predictive logistics management that coordinates material deliveries with construction progress. Real-time demand forecasting, inventory optimization, and delivery scheduling reduce material waste while ensuring continuous construction progress without delays.

The integration of blockchain technology with digital twin platforms offers potential solutions for secure, transparent project documentation and automated contract execution. Smart contracts triggered by verified digital twin data could automate payments, progress milestones, and quality approvals while maintaining comprehensive audit trails.

Future Perspectives and Industry Transformation

The trajectory of digital twin development points toward comprehensive construction industry transformation as underlying technologies continue advancing. 5G networks enable more sophisticated real-time communications, while edge computing capabilities reduce latency and improve system responsiveness for time-critical applications.

The convergence of digital twin technology with other construction innovations including modular construction, 3D printing, and advanced materials will create new possibilities for optimized project delivery. These integrated approaches promise significant improvements in construction speed, quality, and sustainability while reducing overall project costs.

Digital twin platforms are evolving toward comprehensive construction ecosystems that manage entire project lifecycles from initial design concepts through facility decommissioning. These platforms will integrate design optimization, construction management, operational efficiency, and sustainability monitoring into unified systems that maximize value creation throughout building lifecycles.

Conclusion

Digital twin technology represents a fundamental transformation in how the construction industry approaches virtual design and physical construction integration. Organizations successfully implementing comprehensive digital twin strategies gain competitive advantages through improved project outcomes, enhanced operational efficiency, and superior stakeholder satisfaction.

The construction industry’s digital transformation is accelerating as digital twin technology matures and becomes more accessible to organizations of all sizes. Early adopters demonstrate that the benefits of digital twin implementation extend far beyond initial project delivery to encompass operational optimization and lifecycle value creation.

The future of construction lies in the seamless integration of virtual intelligence with physical construction reality. Digital twin technology provides the foundation for this transformation, enabling construction professionals to create better buildings more efficiently while optimizing performance throughout operational lifecycles. Companies that embrace digital twin technology today position themselves as leaders in the construction industry’s digital future.