Cemen Tech has introduced AP Office and AP Mobile, a new set of tools in its ACCU-POUR technology suite available for volumetric concrete mixer users. AP Office and AP Mobile are an all-new cloud-based productivity solution that provides users a complete view of their concrete business operations. The ACCU-POUR technology suite is designed to make an impact on operations of all sizes, giving users more control over their business than ever before.

AP Office

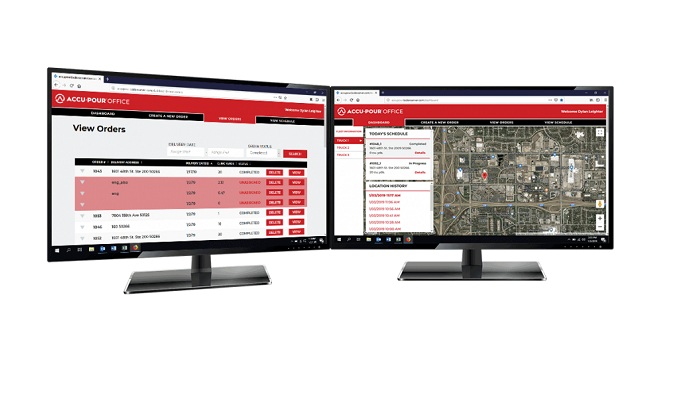

AP Office is the front-end solution for scheduling, dispatch and fleet management functions. Utilizing the latest in telematics technology, the software allows business owners to keep track of the status and location of each mixer in their fleet in real-time. AP Office also documents and stores all key mixer production statistics, which allows users to make accurate real-time business management decisions.

AP Mobile

Designed for use on a phone, tablet of other mobile device, AP Mobile allows users to wirelessly send and receive production data between AP Office and the mixer, as well as view mixing parameters in real-time. Once a pour is complete, final job data syncs automatically with AP Office.

Traditionally, communication with a mobile concrete mixer flowed in one direction – from the unit back to the office typically in paper form. But now, with both AP Office and AP Mobile working jointly in real-time, information goes to the unit and then directly back to the office. After an order is placed, dispatch enters the job parameters into AP Office. AP Mobile then receives those parameters and wirelessly sends all information to the mixer. The operator completes the pour, while all production data is automatically sent back to AP Office for analysis.

AP Office also simplifies assignments and orders by allowing users to create one order, then divide it into multiple trucks if needed and still track under one job. With smart scheduling, users know where their fleet is at any time, where they’re headed next, and if adjustments are needed before the next job begins.

“This year, Cemen Tech celebrates its 50th year in business, so the timing couldn’t be better for us to announce the latest in the ACCU-POUR tech suite to move our industry forward in big steps,” says Connor Deering, CEO/President of Cemen Tech. “The continued development of our ACCU-POUR suite with the new AP Office and AP Mobile modules shows our commitment and leadership in developing the most innovative and advanced volumetric concrete production solutions for the industry. AP Office is not limited to only Cemen Tech equipment, it can be used by anyone who owns a volumetric mixer.”

Real-Time Data Gathering and Reports

Thanks to a nearly endless stream of real-time data, ACCU-POUR acts as a robust business partner day in and day out. This partner presents known and unknown information, allowing you to control and run the business based on current and precise data. But analysis isn’t limited to real-time as all data can be custom exported to many popular accounting programs.

For more information on ACCU-POUR and the entire line of Cemen Tech’s volumetric concrete production solutions, visit www.CemenTech.com or www.ACCU-POUR.com.

About Cemen Tech Inc.

Cemen Tech, Inc. has 50 years manufacturing and engineering experience in the volumetric mixing industry. As the industry leader, the company strives to provide the highest quality concrete mixers to its customers. Cemen Tech currently operates in over 60 countries, services mixers across the globe, and supplies equipment to the United States military. Cemen Tech believes that people, businesses, and communities around the world should have the infrastructure to access clean water, to transport goods and services, and to reliable housing. Their products provide the foundation and stability to meet the needs of a growing world in an environmentally conscious way. www.CemenTech.com

About ACCU-POUR™

Cemen Tech’s proprietary technology suite ACCU-POUR can make an impact in any size of operation. Its tools provide a holistic view of your business operations, from up-to-the-minute to a yearly overview. Blend the big picture together with everyday details and gain complete control over your concrete through ACCU-POUR. www.ACCU-POUR.com