Speed and accuracy are crucial in the creation and production sectors to ensure that industry gamers stay aggressive and can meet customer demands. Automated laser cutting in steel fabrication and high-speed CNC machining services are the number one technology which have improved the machining method for components. Sustainable production technologies. As process times are shortened, precision improved, and material waste reduced, those technologies play a key role in efficient object manufacturing procedures.

In this article, we explore how these advancements have transformed the fabrication process, making it faster, more cost-effective, and environmentally friendly.

The Need for Speed and Precision in Fabrication

The manufacturing of structural components is very important in construction, aerospace, and automotive industries. Time savings within production is a factor that can greatly affect delivery times and costs, but shouldn’t be at the detriment of quality. These traditional supplies, though accurate, are slower and are subject to human error that can cause errors or delays.

Enter automated laser cutting in steel fabrication and high-speed CNC machining services, two technologies that have reshaped the rate and accuracy of fabrication. These innovations permit faster production times whilst preserving the high precision needed for structural components.

What is Automated Laser Cutting in Steel Fabrication?

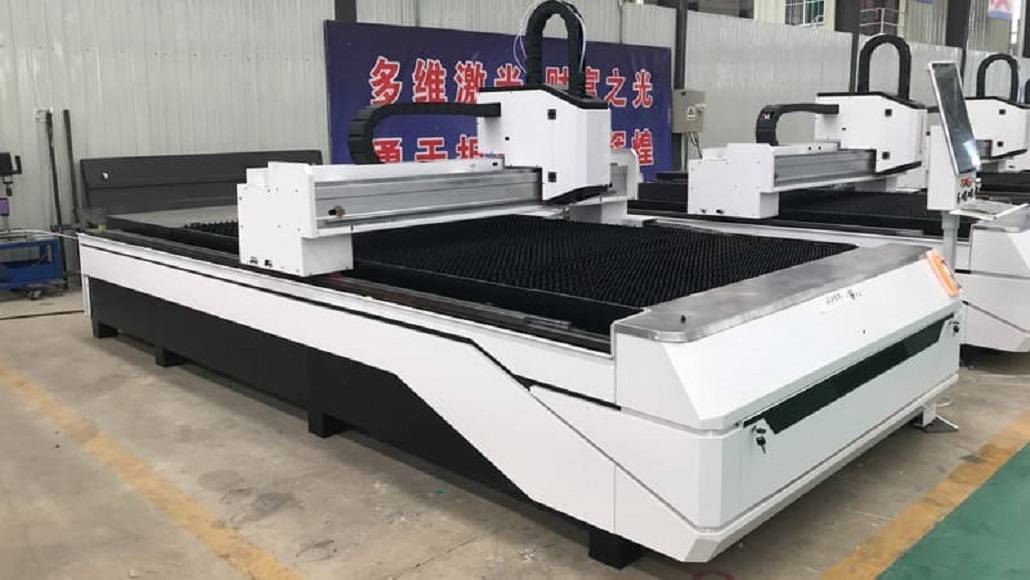

Automated laser cutting in steel fabrication utilizes a focused laser to melt through materials, including metals, with extreme accuracy. A computer system directs this automated system, making sure the system is both unique and quick. In comparison to conventional cutters, laser cutters do not require bodily touch with the fabric, which reduces wear and tear on the device and increases cutting speeds.

Key Benefits of Automated Laser Cutting:

- Precision: The excessive accuracy of laser cutting makes it best for slicing elaborate shapes and fine details.

- Speed: Automated systems operate efficiently, significantly reducing production time.

- Efficiency: Reduced setup time and fewer material errors mean less waste and faster completion of projects.

The Role of High-Speed CNC Machining Services

The principle of the usage of high-speed CNC machining services to improve the machining technique. CNC machines can reduce, bore, and shape cloth with top-notch precision, resulting in satisfactory elements. As the excessive-pace CNC era has become available, those collections have evolved into quicker machines with reduced cycle times while maintaining their precision.

Why High-Speed CNC Machining Matters:

- Faster Turnaround: High-speed CNC machines operate at significantly faster speeds than conventional machines, thereby reducing fabrication time.

- Consistency: Automated CNC structures provide uniform results, ensuring that components are consistently manufactured to specification.

- Flexibility: CNC machines can handle a wide range of materials, from metals to plastics, making them suitable for various fabrication needs.

How Automation and CNC Laser Cutting Improve Fabrication Speed

The combination of automated laser cutting in steel fabrication and high-speed CNC machining services offers unparalleled performance in the fabrication process. Here’s how those technologies work collectively to enhance production speeds:

Streamlining the Cutting Process

- Automated laser cutting gets rid of manual labor, permitting machines to cut steel components quickly and accurately.

- High-speed CNC machining works in conjunction with laser cutting, aided by additional processing additives and precision machining, thereby reducing the need for secondary operations.

Minimizing Downtime

- Automation reduces human mistakes and the want for manual interventions, leading to fewer mistakes and interruptions at some stage in the fabrication method.

- With faster device changes and non-stop operation, CNC structures preserve manufacturing traces, walking smoothly.

Reducing Material Waste

- Laser cutting offers a minimal kerf width, resulting in less cloth loss during the cutting process.

- Both technologies optimize cloth utilization, which reduces waste and results in more valuable production.

Advantages of Integrating Automation and CNC Technologies

When combined, automated laser cutting in steel fabrication and high-speed CNC machining services deliver a multitude of benefits for businesses aiming to improve their fabrication processes:

Increased Productivity

- Automation allows for 24/7 manufacturing without the need for breaks, leading to continuous excessive-pace production.

- High-speed CNC machining services enable faster production runs, contributing to improved throughput.

Improved Quality Control

- Automation guarantees constant fines, as machines perform obligations with an excessive degree of precision, reducing defects and errors.

- Both CNC machining and laser cutting may be programmed for repeatability, ensuring that each element is made to exact specifications..

Cost Savings

- Reduced material waste and fewer errors result in significant cost savings, especially on large-scale projects.

- With faster production times, companies can meet deadlines more easily, improving profitability.

The Future of CNC Laser Cutting and Automation in Fabrication

Into the future, and with technology ever improving, the demand for automated laser cutting within steel fabrication, as well as high-speed CNC machining services, will only increase:

Advancements in Automation

- AI and Machine Learning: AI and Machine Learning: Future CNC Machines and laser cutters will come with AI that would optimize, automate, and thus minimize paths and downtime too.

- Smart Factories: IoT (Internet of Things) integration will allow machines to communicate with one another, thereby resulting in more efficient manufacturing lines.

Sustainability

- With industries’ emphasis on sustainability, automatic laser cutting and CNC machining are going to make production greener as textile wastes become less and electricity consumption is reduced.

Conclusion

In summary, automated laser cutting in steel fabrication and high-speed CNC machining services are a game-changer for any industry that requires structural components. The fabrication speed can be greatly increased, and product precision, material saving ratio and production cost can all be lowered with such technologies.

Through this evolution in the world of manufacturing and production technologies, businesses which invest in automation systems and CNC machines will find themselves in pole position on the market: a fact that helps not only their profit margins but also minimises damaging effects on the environment.