With the funding round led by EquipmentShare, with backing from Brick & Mortar Ventures, Chattanooga Renaissance Fund and other previous investors, Branch Technology will be able to develop even further. The company plans to expand its team further, incorporating experts in building science, software and engineering. Additionally, it aims to grow its fleet of 3D printers and its overall capabilities.

Branch Technology developed a method called Cellular Fabrication (C-Fab) for 3D printing polymer lattice structures that could then be sprayed with insulation and concrete to create extremely lightweight, yet structurally impressive prefab components.

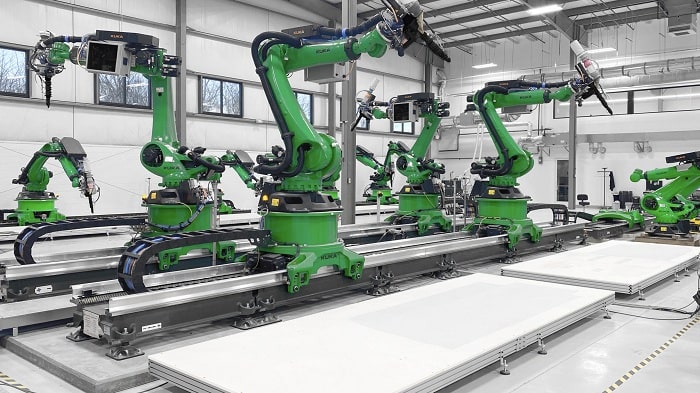

The process relies on industrial robotic arms outfitted with polymer extruders and attached to massive rails, resulting in one of the largest freeform 3D printing systems yet. According to the firm, elements 3D printed with C-Fab use 20 times less material than traditional layered printing, while still enabling remarkable strength-to-weight ratios.