Modernising Lifting Systems on Construction Sites

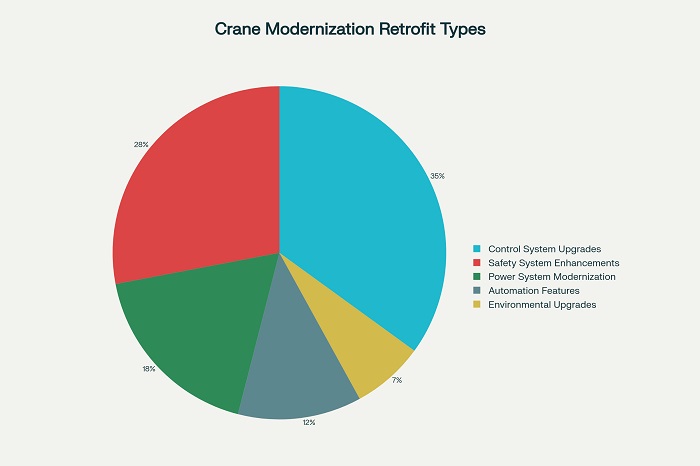

Construction sites worldwide continue operating thousands of legacy cranes and hoists that, despite their age, retain substantial mechanical integrity and lifting capacity. These machines represent significant capital investments, yet their obsolete control systems, outdated safety features, and limited diagnostic capabilities increasingly constrain operational efficiency and safety performance. Modernising lifting systems construction through strategic retrofits and upgrades offers construction companies pathways to extend equipment lifecycles, enhance safety protocols, and improve productivity without incurring the substantial costs associated with complete equipment replacement.

Strategic Assessment and Modernization Planning

Effective modernization begins with comprehensive assessment of existing lifting equipment conditions, capabilities, and limitations. Engineers evaluate structural components for fatigue, corrosion, and damage that might compromise continued operation. Mechanical systems undergo detailed inspection to identify worn bearings, damaged gears, or degraded hydraulic components requiring replacement. Electrical systems are analyzed to determine which elements can be retained and which require updating to support modern control architectures.

Economic analysis plays crucial roles in modernization decisions. Engineers compare retrofit costs against new equipment purchases, considering factors beyond initial expenditure. Remaining structural life, anticipated usage intensity, and operational requirements all influence whether modernization represents sound investment. Generally, when existing equipment retains seventy percent or more of its useful structural life and modernization costs remain below thirty percent of replacement costs, retrofits prove financially advantageous.

Operational requirements drive modernization scope definitions. Construction companies operating multiple identical cranes can achieve substantial economies by developing standardized retrofit packages applicable across their fleets. This approach reduces engineering costs, simplifies spare parts management, and accelerates installation through repetition. Companies managing diverse equipment portfolios may require customized solutions addressing specific machine configurations and operational needs.

Drive and Control System Modernization

Obsolete drive and control systems constitute the primary limitation affecting legacy lifting equipment. Original systems often relied on contactors, relays, and thyristor drives that manufacturers no longer support with replacement parts or technical assistance. Modern frequency converter drives offer substantial advantages, providing smoother acceleration, regenerative braking capabilities, and precise speed control while reducing energy consumption and mechanical stress.

Programmable logic controllers form the foundation of contemporary crane control systems. These units replace aging relay logic with flexible, programmable architectures supporting advanced features and simplified troubleshooting. Modern PLCs communicate via Ethernet, Profinet, and Profibus protocols, enabling integration with terminal operating systems, fleet management platforms, and remote monitoring applications. This connectivity transforms isolated machines into networked assets providing continuous operational data.

Operator interfaces receive substantial upgrades during control system modernization. Obsolete analog displays and mechanical switches give way to intuitive touchscreen panels presenting comprehensive operational information. These interfaces display real-time load data, system diagnostics, maintenance alerts, and historical performance trends. Operators gain unprecedented visibility into crane conditions, enabling informed decision-making and proactive issue identification.

Crane management systems integrated during modernising lifting systems construction provide sophisticated diagnostic capabilities previously unavailable on legacy equipment. These systems continuously monitor hundreds of operational parameters, identifying anomalies that might indicate developing problems. Maintenance personnel receive detailed fault information accelerating troubleshooting processes. Remote diagnostic capabilities enable manufacturer support personnel to analyze issues and provide guidance without requiring site visits.

Safety System Enhancement and Integration

Modern safety systems represent critical modernization components addressing regulatory requirements and risk management objectives. Anti-collision systems become essential when multiple cranes operate in proximity, using sensors and communication networks to monitor crane positions and prevent contact. These systems calculate safe operating zones dynamically, issuing warnings when cranes approach dangerous proximities and automatically limiting movements that would result in collisions.

Load moment limiters prevent dangerous operating conditions by continuously calculating actual loads against crane capacities at current configurations. Advanced systems account for boom angles, radii, wind loads, and dynamic forces, providing real-time capacity information and automatically preventing movements exceeding safe limits. Integration with control systems enables sophisticated protection strategies that balance operational flexibility with safety requirements.

Emergency descent systems ensure that loads can be lowered safely during power failures or hydraulic system malfunctions. Modern implementations use sophisticated valving arrangements and secondary power sources enabling controlled descents even under adverse conditions. These systems provide critical safety margins protecting personnel and equipment when primary systems fail.

Operator assistance features incorporated during modernization reduce workload and improve safety. Sway control systems use accelerometers and sophisticated algorithms to minimize load oscillations, particularly valuable in windy conditions or when moving loads across significant distances. Automatic positioning systems guide hooks to predetermined locations with high precision, reducing positioning time and operator stress.

Automation Readiness and Incremental Enhancement

Construction sites increasingly embrace automation technologies that promise enhanced efficiency and safety. Modernization programs can position legacy equipment for future automation integration by establishing necessary foundational capabilities. Communication interfaces, sensor integration, and control system architectures implemented during modernization facilitate subsequent automation system additions.

Remote operation capabilities represent intermediate steps toward full automation. Modernized cranes can incorporate remote operating stations enabling operators to control equipment from ground-level locations rather than crane cabs. These systems utilize high-definition cameras providing comprehensive visual coverage combined with control interfaces mirroring cab-mounted equipment. Remote operation improves operator comfort, reduces fatigue, and enables single operators to manage multiple cranes sequentially.

Partial automation features can be implemented incrementally as operational experience and comfort levels increase. Automated positioning sequences reduce repetitive manual operations during container handling or material placement activities. Load management systems can automate pick-and-place operations following predetermined paths and sequences. These implementations provide automation benefits while maintaining human oversight and decision-making authority.

Power System Upgrades and Energy Efficiency

Power system modernization addresses both performance and sustainability objectives. Legacy cranes often utilized inefficient motor-generator sets or basic electrical systems lacking energy recovery capabilities. Modern implementations incorporate variable frequency drives enabling precise motor speed control while substantially reducing energy consumption compared to conventional systems.

Regenerative systems capture energy during lowering operations and braking events, converting mechanical energy into electrical power that recharges batteries or returns to site electrical systems. This capability reduces overall energy requirements significantly, particularly for operations involving repetitive lifting cycles. The energy savings translate directly to reduced operating costs and decreased environmental impacts.

Power quality improvements benefit both modernized equipment and site electrical systems. Modern drives incorporate active filtering reducing harmonics injected into electrical distribution networks. Power factor correction systems minimize reactive power demands, reducing utility charges and improving electrical system efficiency. These enhancements create value extending beyond individual crane operations.

Implementation Strategy and Downtime Management

Successful modernization programs require careful planning minimizing equipment downtime during retrofit implementation. Manufacturers typically assemble and test retrofit components comprehensively before shipping to construction sites, reducing on-site installation time. Depending on scope, modernization installations require seven to fourteen days of equipment unavailability for component installation, wiring, testing, and commissioning.

Project scheduling coordinates modernization activities with natural project breaks or periods of reduced equipment demand. Companies operating multiple cranes can stage retrofits maintaining operational capacity while individual machines undergo upgrading. Rental equipment may bridge temporary capacity shortages during modernization programs.

Operator training constitutes essential modernization program elements. New control systems, interfaces, and operational procedures require thorough familiarization ensuring safe, effective equipment operation. Training programs should address not only mechanical operation but also interpretation of diagnostic information, response to system alerts, and troubleshooting procedures. Comprehensive training accelerates productivity recovery following modernization completion.

Return on Investment and Long-Term Benefits

Modernising lifting systems construction provides construction companies with cost-effective pathways to enhance safety, improve efficiency, and extend equipment service lives. Strategic retrofits transform aging cranes into technologically current assets incorporating modern safety features, diagnostic capabilities, and operational efficiencies. Companies implementing comprehensive modernization programs typically report twenty to forty percent improvements in equipment availability, substantial reductions in maintenance costs, and enhanced compliance with evolving safety regulations.

The financial benefits extend beyond direct operational savings. Modernized equipment commands higher utilization rates and rental values compared to obsolete machinery. Insurance costs often decrease when companies demonstrate proactive safety system implementation. Worker productivity improves through enhanced operator interfaces and reduced equipment downtime.

As equipment ages and replacement costs escalate, modernization increasingly represents prudent investment strategy balancing performance requirements against financial constraints. Construction companies that strategically modernize their lifting fleets position themselves competitively while maintaining operational flexibility and equipment reliability.