Heavy Lift Design and Risk Management Construction

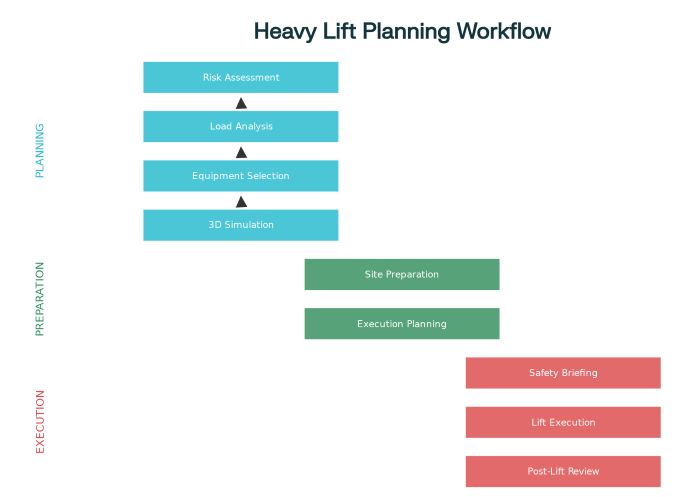

Heavy lifting operations represent critical path activities that can determine project success or failure through their profound impacts on safety, schedule, and cost. These complex maneuvers involve coordinating massive equipment, precisely positioning multi-ton loads, and managing numerous interdependent variables where small errors can cascade into catastrophic consequences. Smart strategies for heavy lift design risk management construction integrate advanced planning methodologies, sophisticated simulation technologies, rigorous engineering analysis, and comprehensive risk assessment processes that transform inherently dangerous operations into controlled, predictable activities.

Comprehensive Planning Methodologies

Effective heavy lift operations begin months before equipment arrives on construction sites through detailed planning processes that examine every operational aspect. Engineers must first establish fundamental load parameters including accurate weight determinations accounting for all components, rigging equipment, and potential moisture absorption or ice accumulation. Center of gravity calculations prove critical because even minor miscalculations can result in unstable loads during lifting. Three-dimensional modeling helps visualize load geometry, identifying potential interference points and clearance challenges.

Lift planning software has revolutionized preparation processes by enabling engineers to simulate operations digitally before committing resources to field execution. These sophisticated programs maintain extensive crane databases incorporating detailed specifications for hundreds of equipment models from multiple manufacturers. Engineers input site conditions, load characteristics, and operational constraints, then evaluate numerous equipment and positioning alternatives. The software calculates capacity margins, ground bearing pressures, and clearance dimensions automatically, identifying configurations that satisfy all requirements.

Sequential analysis addresses projects involving multiple interdependent lifts where equipment positioning for one operation affects subsequent activities. Advanced planning tools can optimize lift sequences minimizing crane repositioning, reducing ground preparation requirements, and shortening overall project durations. Automated sequencing algorithms evaluate thousands of potential arrangements, identifying solutions that would prove impractical to discover through manual analysis.

Site-specific conditions receive thorough evaluation during planning phases. Ground bearing capacity analysis determines whether native soils can support crane loads or require reinforcement through steel plates, timber mats, or engineered fill placement. Overhead clearances must account for power lines, existing structures, and temporary facilities. Underground utilities require identification and protection strategies. Wind exposure analysis evaluates how site topography and surrounding structures affect wind loads on suspended components.

Engineering Analysis and Structural Verification

Rigorous engineering analysis verifies that all components involved in heavy lift operations possess adequate strength and stability margins. Crane capacity calculations must account for dynamic factors including acceleration forces, wind loads, and potential shock loading. Engineers evaluate equipment at specific boom configurations, load radii, and counterweight arrangements, ensuring selected cranes operate within rated capacities throughout entire lifting sequences including pick, swing, travel, and placement phases.

Rigging design constitutes critical engineering elements requiring detailed analysis. Sling arrangements must distribute loads appropriately across lifting points while accommodating geometric constraints and minimizing eccentric loading. Sling angle calculations determine tension forces in individual sling legs; shallow angles create dramatically higher tensions potentially exceeding sling capacities even when total loads remain moderate. Shackles, hooks, and other rigging hardware receive verification ensuring adequate capacity with appropriate safety factors.

Structural analysis of lifted components ensures they can withstand handling stresses. Large fabricated assemblies may require temporary bracing or stiffening during lifting operations to prevent deformation or damage. Finite element analysis models structural behavior under various loading conditions, identifying areas experiencing excessive stress and guiding reinforcement strategies. Dynamic analysis accounts for oscillations and impact loads that may occur during transportation and positioning.

Ground support systems receive comprehensive engineering evaluation. Temporary foundations supporting cranes must distribute loads across adequate areas preventing settlement or failure. Bearing pressure calculations account for maximum crane reactions occurring during peak load moments. Foundation designs must consider dynamic loading from wind gusts, emergency stops, and load repositioning. Slope stability analysis addresses situations where cranes operate near excavations or embankments.

Risk Assessment and Mitigation Strategies

Systematic risk assessment methodologies identify potential hazards throughout heavy lift operations, evaluate their likelihood and consequences, and establish appropriate control measures. Hazard identification workshops bring together lift planners, engineers, crane operators, riggers, and safety professionals to examine operations from multiple perspectives. These collaborative sessions often reveal concerns that individual participants might overlook, creating comprehensive hazard inventories.

Risk matrices provide structured frameworks for evaluating identified hazards. Each hazard receives likelihood and severity ratings based on historical data, engineering judgment, and site-specific factors. Risks falling into high categories require mandatory control measure implementation before operations proceed. Medium risks necessitate additional precautions beyond standard practices. Even low-level risks warrant documentation ensuring awareness and preparedness.

Control measure hierarchies prioritize elimination over mitigation wherever feasible. Can loads be reduced through modular construction approaches? Can ground assembly replace high-altitude assembly? When hazards cannot be eliminated, engineering controls provide next preference. Can guardrails prevent falls? Can load positioning systems reduce operator exposure? Administrative controls and personal protective equipment constitute final resort options when higher-level controls prove impractical.

Specific hazards commonly identified during heavy lift design risk management construction assessments include crane instability from inadequate ground support, structural failure of lifted components, rigging equipment failure from overloading or damage, contact with overhead power lines, personnel struck by loads or equipment, and weather conditions affecting safe operations. Each hazard requires tailored control strategies addressing root causes and implementing multiple protection layers.

Advanced Simulation and Visualization Technologies

Three-dimensional lift planning software enables comprehensive visualization of operations before field execution. Engineers create detailed site models incorporating existing structures, temporary facilities, utilities, and topography. Crane models positioned digitally can be manipulated to simulate entire lift sequences, automatically checking for collision potential between equipment, loads, and site features. These visualizations prove invaluable for identifying clearance issues, optimizing crane positioning, and verifying operational feasibility.

Animation capabilities transform static plans into dynamic simulations showing equipment movements, load paths, and temporal progressions. Project stakeholders can observe planned operations from various vantage points, developing comprehensive understanding of activities and identifying potential concerns. Operators benefit from reviewing simulations before field execution, familiarizing themselves with planned movements and developing mental models of upcoming operations.

Four-dimensional scheduling integration links lift simulations with project timelines, enabling evaluation of how lifting operations affect overall schedules. Engineers can identify critical path activities, assess schedule risks, and develop contingency plans addressing potential delays. The integration facilitates communication with project management teams, ensuring lifting considerations receive appropriate attention during schedule development.

Ground reaction calculations integrated into simulation platforms determine bearing pressures throughout lift sequences as loads shift and cranes move. Engineers can identify peak loading conditions requiring additional ground reinforcement. Influence diagrams show how ground pressures vary spatially, guiding timber mat placement and steel plate positioning. These analyses prove particularly valuable for operations on marginal soils where ground support requires careful engineering.

Operational Control and Real-Time Management

Comprehensive lift plans translate engineering analysis and risk assessments into detailed operational procedures. These documents specify equipment configurations, rigging arrangements, personnel assignments, communication protocols, and step-by-step execution sequences. Lift directors utilize plans as operational guides while retaining authority to halt operations if conditions deviate from planned parameters.

Pre-lift meetings gather all participants to review plans, clarify roles, discuss hazards, and address questions. These briefings ensure common understanding of operational objectives and safety requirements. Designated personnel receive specific assignments including rigging verification, load monitoring, exclusion zone enforcement, and emergency response. Communication methods receive establishment including radio protocols and hand signal standardization.

Real-time monitoring during lift execution provides continuous verification that operations proceed within acceptable parameters. Load moment indicators display actual loads relative to crane capacities, alerting operators when approaching limits. Wind speed monitoring enables immediate assessment whether conditions remain within acceptable ranges. Crane inclination indicators verify stability throughout operations. These monitoring systems provide objective data supporting operational decision-making.

Emergency procedures address potential scenarios including equipment malfunctions, sudden weather changes, or personnel injuries. Plans specify load securing methods enabling safe suspension during temporary stoppages. Emergency lowering procedures enable controlled load placement if operations cannot continue. Medical response protocols ensure rapid access to injured personnel. Regular emergency drills verify team preparedness and identify procedure improvements.

Technology Integration and Innovation

Modern heavy lift operations increasingly incorporate advanced technologies enhancing safety and precision. Wireless load monitoring systems provide real-time weight information throughout lifting sequences, enabling operators to verify loads remain within acceptable limits. GPS positioning systems track crane and load locations with centimeter-level accuracy, supporting precise placement and collision avoidance.

Automated crane functions reduce operator workload and human error potential. Load block positioning systems guide hooks to predetermined coordinates using GPS and inertial guidance. Anti-collision systems prevent crane-to-crane contact on sites with multiple equipment. These technologies enable more complex operations while maintaining or improving safety margins.

Communication systems ensure coordination among team members. Digital radios provide clear audio communications while recording conversations for post-operation analysis. Visual communication systems using cameras and displays enable supervisors to monitor operations from safe locations while maintaining real-time awareness of activities.

Continuous Improvement and Learning

The integration of smart strategies for heavy lift design risk management construction creates frameworks enabling inherently complex, dangerous operations to proceed with acceptable safety margins and high success probabilities. Comprehensive planning identifies optimal approaches, engineering analysis verifies adequacy, risk assessment establishes appropriate controls, simulation validates feasibility, and operational discipline ensures execution fidelity.

Post-operation reviews capture lessons learned and identify improvement opportunities. These analyses examine planning accuracy, execution effectiveness, and any deviations from planned procedures. Documentation of successful practices and identified improvements supports continuous enhancement of organizational capabilities. Regular training updates ensure teams remain current with evolving technologies and best practices.

Organizations implementing these sophisticated methodologies demonstrate consistently superior safety performance and project outcomes compared to those relying primarily on operator experience and intuition. The systematic approach transforms high-risk activities into managed operations where success becomes predictable rather than fortuitous.