Revolutionizing Equipment Management in Construction: The Role of Sensor Technologies and Predictive Insights

The construction industry is experiencing a technological revolution driven by advanced sensor technologies that transform traditional equipment management into sophisticated continuous performance assessment systems. These intelligent monitoring solutions leverage Internet of Things (IoT) connectivity, machine learning analytics, and real-time data processing to provide unprecedented visibility into equipment health, operational efficiency, and maintenance requirements. With equipment failures costing contractors an average of $95,000 per incident and traditional maintenance approaches missing 70% of developing problems, sensor-based monitoring systems represent essential tools for modern construction operations.

Understanding Advanced Sensor Technologies in Construction Equipment

Modern construction equipment sensor technologies encompass a diverse array of measurement devices designed to monitor critical operational parameters including vibration patterns, temperature variations, pressure levels, load distributions, and environmental conditions. These sensors collect continuous data streams that enable continuous performance assessment systems to identify developing problems weeks before visible symptoms appear, facilitating proactive maintenance interventions that prevent catastrophic failures.

The global IoT in construction market demonstrates the technology’s growing importance, expanding from USD 14.8 billion in 2023 with projected growth at over 14.1% compound annual growth rate through 2032. This remarkable expansion reflects industry recognition that sensor-based monitoring systems deliver measurable value through reduced downtime, extended equipment lifespans, and improved operational safety.

Contemporary sensor systems integrate multiple measurement technologies including accelerometers, thermistors, strain gauges, pressure transducers, and environmental monitors into comprehensive monitoring networks. These devices achieve remarkable sensitivity levels, with modern vibration sensors detecting changes as small as 0.1mm/s and temperature sensors providing accuracy within 0.1°C, enabling early detection of developing problems that human inspection methods cannot identify.

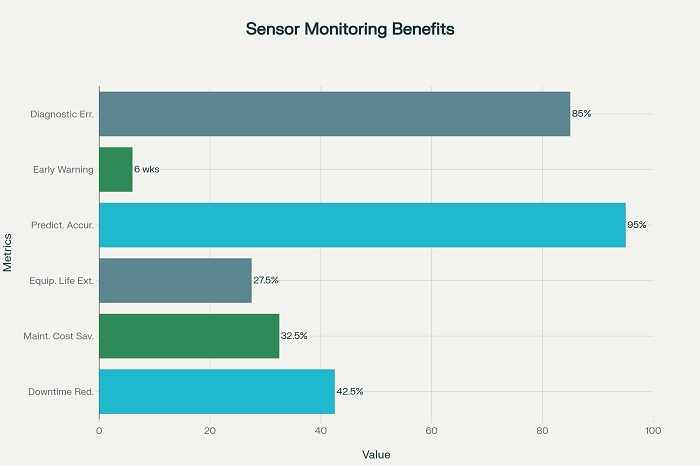

The sophistication of these systems extends beyond simple data collection to encompass advanced analytics capabilities that transform raw sensor data into actionable intelligence. Machine learning algorithms analyze operational patterns, identify anomalies, and predict maintenance requirements with accuracy levels exceeding 95% in controlled studies. This analytical capability enables construction teams to transition from reactive maintenance approaches to proactive strategies that optimize equipment availability and performance.

Comprehensive Vibration Analysis for Mechanical Component Monitoring

Vibration analysis represents the cornerstone of modern predictive maintenance programs, providing early warning capabilities for mechanical component degradation in construction equipment. Continuous performance assessment systems equipped with advanced accelerometers monitor vibration signatures across multiple frequency ranges, detecting subtle changes that indicate bearing wear, misalignment, imbalance, and component looseness long before visible symptoms develop.

Modern vibration sensors achieve sampling rates up to 20kHz with sensitivity levels that exceed human detection capabilities by orders of magnitude. These sensors continuously monitor critical components including engines, transmissions, hydraulic pumps, and drive systems, creating baseline patterns during normal operation and identifying deviations that signal developing problems. Advanced algorithms analyze frequency spectra to distinguish between different fault types and assess severity levels with remarkable precision.

Engine bearing failure detection through vibration analysis provides early warning 4-8 weeks before breakdown occurrence, preventing repair costs ranging from $45,000 to $85,000 per incident. The technology monitors subtle changes in vibration patterns that indicate bearing wear progression, enabling maintenance teams to schedule planned replacements during convenient downtime periods rather than responding to catastrophic failures.

Transmission and drivetrain monitoring capabilities prevent 90% of gear-related failures through early detection of wear patterns, misalignment conditions, and lubrication problems. These systems analyze gear mesh frequencies, identifying developing problems that could result in transmission failures costing $35,000 to $65,000 per incident. Early intervention based on vibration analysis extends component lifespans while maintaining operational reliability.

Hydraulic system monitoring through vibration analysis detects pump degradation, valve problems, and system contamination with 95% accuracy in predicting component failures. Modern construction equipment relies heavily on hydraulic systems for critical functions, making early problem detection essential for maintaining operational capability. Vibration monitoring identifies developing issues that could result in hydraulic failures costing $25,000 to $55,000 per incident.

Thermal Monitoring Systems for Temperature-Critical Applications

Temperature monitoring represents another crucial component of comprehensive equipment health assessment, as thermal conditions directly impact component longevity, operational efficiency, and safety performance. Continuous performance assessment systems integrate multiple temperature sensors throughout construction equipment to monitor engine operating temperatures, hydraulic fluid conditions, electrical system heat generation, and environmental factors that influence equipment performance.

Engine cooling system monitoring through advanced temperature sensors provides early warning of cooling system failures, overheating conditions, and thermal stress situations that could result in catastrophic engine damage. These systems monitor coolant temperatures, oil temperatures, and exhaust gas temperatures to identify developing problems before they compromise engine integrity. Overheating prevention through thermal monitoring prevents engine failures that typically cost $50,000 to $150,000 per incident.

Hydraulic system temperature monitoring ensures optimal fluid viscosity, prevents thermal breakdown of hydraulic fluids, and identifies system inefficiencies that increase operating temperatures. High hydraulic fluid temperatures indicate system problems including pump wear, filter contamination, or excessive system pressure that could lead to component failures. Temperature monitoring enables early intervention to address these issues before expensive repairs become necessary.

Electrical system thermal monitoring detects overheating conditions in wiring harnesses, control modules, and power distribution systems that could result in electrical failures or fire hazards. Modern construction equipment contains sophisticated electrical systems that generate significant heat during operation. Temperature sensors monitor critical electrical components, providing warnings when thermal conditions exceed safe operating limits.

Bearing and component temperature monitoring through infrared sensors and embedded thermistors identifies developing problems in rotating machinery, drive systems, and mechanical components. Excessive temperatures in bearings, gearboxes, and mechanical systems indicate lubrication problems, misalignment issues, or component wear that requires maintenance attention. Early detection prevents component failures while extending equipment lifespans.

Advanced Load and Stress Monitoring Capabilities

Structural load monitoring represents a critical safety and performance management application for continuous performance assessment systems in construction equipment. Load cells, strain gauges, and pressure sensors monitor forces, stresses, and loading conditions throughout equipment operation, ensuring safe working limits while optimizing productivity and preventing structural damage.

Crane load monitoring systems provide real-time assessment of lifting loads, boom stresses, and stability conditions to prevent overloading situations that could result in catastrophic failures. These systems integrate multiple sensors to monitor load weights, boom positions, and outrigger reactions, providing operators with continuous feedback about safe operating envelopes. Load monitoring prevents crane accidents while optimizing lifting productivity through accurate load assessment.

Excavator boom and arm stress monitoring through strain gauge networks detects overloading conditions, structural fatigue development, and component degradation that could compromise equipment integrity. These systems monitor structural stresses throughout digging cycles, identifying operating patterns that could lead to premature component failure. Stress monitoring achieves 92% accuracy in identifying overload conditions while extending equipment life by 35% through proper usage management.

Equipment stability monitoring through inclinometer sensors and level detection systems prevents rollover accidents and ensures safe operation on uneven terrain. Construction sites often present challenging ground conditions that could compromise equipment stability. Advanced monitoring systems continuously assess equipment orientation and stability, providing warnings when conditions approach dangerous limits.

Foundation and support structure monitoring for construction equipment operating on temporary foundations or elevated platforms ensures structural adequacy and prevents collapse scenarios. Load monitoring systems verify that temporary structures can safely support equipment loads while identifying developing structural problems that could compromise safety. These systems prevent accidents while enabling safe equipment operation in challenging environments.

Environmental and Operational Condition Monitoring

Environmental monitoring capabilities within continuous performance assessment systems provide comprehensive assessment of operating conditions that influence equipment performance, safety, and longevity. Advanced sensor networks monitor air quality, weather conditions, ground stability, and other environmental factors that impact construction operations.

Air quality monitoring through particulate sensors, gas detectors, and atmospheric analyzers ensures safe working conditions while identifying environmental factors that could affect equipment performance. Dust exposure monitoring protects equipment from excessive contamination while ensuring compliance with environmental regulations. These systems provide early warning of hazardous atmospheric conditions that could endanger workers or damage equipment.

Weather condition monitoring through integrated meteorological sensors provides real-time assessment of wind speeds, precipitation, temperature, and humidity levels that influence safe equipment operation. Weather monitoring enables proactive decisions about suspending operations during dangerous conditions while optimizing productivity during favorable weather periods. These systems prevent weather-related accidents while maintaining operational efficiency.

Ground stability monitoring through geotechnical sensors assesses soil conditions, settlement patterns, and foundation stability that affect equipment operation and safety. Construction sites often present challenging ground conditions that could compromise equipment stability or foundation integrity. Ground monitoring systems provide early warning of unstable conditions while enabling safe equipment deployment.

Fuel quality and consumption monitoring through advanced sensor systems optimizes equipment efficiency while identifying fuel-related problems that could affect performance. These systems monitor fuel quality parameters, consumption rates, and injection system performance to optimize engine efficiency and prevent fuel-related component damage. Fuel monitoring typically reduces consumption by 10-15% while extending engine lifespans.

Integration with Predictive Analytics and Machine Learning

The evolution of continuous performance assessment systems increasingly incorporates sophisticated analytics platforms that transform raw sensor data into predictive intelligence and actionable maintenance recommendations. Machine learning algorithms analyze historical operational patterns, current sensor readings, and environmental conditions to forecast equipment failures with unprecedented accuracy while optimizing maintenance scheduling.

Predictive maintenance algorithms process multiple sensor data streams simultaneously to identify complex failure modes that single-parameter monitoring might miss. These systems recognize patterns in vibration signatures, temperature trends, load cycles, and operational parameters that collectively indicate developing problems. Advanced algorithms achieve failure prediction accuracy rates exceeding 95% while providing 4-8 week advance warning for major component failures.

Remaining useful life estimation through predictive analytics enables optimized maintenance scheduling and parts inventory management. These systems analyze component degradation patterns to forecast when maintenance interventions will become necessary, enabling proactive parts procurement and maintenance scheduling. Accurate remaining useful life predictions reduce maintenance costs by 25-30% while minimizing unscheduled downtime.

Performance optimization through continuous monitoring and analytics identifies operational patterns that maximize equipment efficiency while minimizing wear and tear. These systems analyze operator behaviors, load patterns, and environmental conditions to recommend operating practices that extend equipment lifespans and reduce fuel consumption. Performance optimization typically improves equipment efficiency by 15-20% while extending component lifespans.

Anomaly detection capabilities identify unusual operational patterns that could indicate emerging problems, operator training needs, or equipment misuse. Advanced analytics platforms establish normal operating patterns for individual pieces of equipment and identify deviations that warrant investigation. Early anomaly detection enables proactive interventions that prevent minor issues from developing into major problems.

Implementation Strategies and Best Practices

Successful deployment of continuous performance assessment systems requires strategic approaches to sensor selection, installation, data management, and organizational integration. Companies must carefully evaluate their specific monitoring requirements, existing infrastructure capabilities, and operational workflows to design effective monitoring solutions.

Sensor selection considerations include measurement range requirements, accuracy specifications, environmental durability, and communication capabilities that align with specific monitoring objectives. Different applications require different sensor characteristics, and careful selection ensures optimal performance while controlling implementation costs. Proper sensor selection typically determines 60-70% of overall system effectiveness.

Installation best practices encompass sensor placement optimization, mounting techniques, wiring protection, and calibration procedures that ensure accurate measurements and long-term reliability. Proper installation requires understanding of equipment vibration patterns, thermal conditions, and environmental exposures that could affect sensor performance. Professional installation typically improves sensor reliability by 40-50% compared to suboptimal approaches.

Data management strategies address communication protocols, data storage requirements, analytics platform selection, and integration with existing management systems. Effective data management enables real-time monitoring while supporting long-term trend analysis and predictive modeling. Comprehensive data management typically improves maintenance decision accuracy by 30-40%.

Training and organizational integration ensure that maintenance teams can effectively interpret sensor data, respond to alerts, and integrate monitoring information into maintenance workflows. Successful implementation requires developing organizational capabilities for data-driven maintenance decision-making. Comprehensive training programs typically improve monitoring system effectiveness by 50-60%.

Economic Benefits and Return on Investment Analysis

The implementation of comprehensive continuous performance assessment systems delivers substantial economic returns through multiple value streams including reduced maintenance costs, improved equipment availability, extended asset lifespans, and enhanced operational safety. Organizations typically achieve payback periods ranging from 6-18 months depending on implementation scope and equipment criticality.

Maintenance cost reductions represent the most immediate and measurable benefit from sensor-based monitoring systems. Early problem detection enables planned maintenance interventions that cost 3-5 times less than emergency repairs while preventing collateral damage that often accompanies equipment failures. Companies report average maintenance cost reductions of 25-40% within the first year of comprehensive monitoring implementation.

Equipment availability improvements through reduced unscheduled downtime provide significant productivity benefits that often exceed direct maintenance cost savings. Predictive maintenance based on sensor monitoring reduces unscheduled downtime by 35-50% while enabling more efficient planned maintenance scheduling. Improved equipment availability typically generates 2-3 times more value than direct maintenance cost savings.

Asset lifespan extension through optimized maintenance and operating practices provides long-term value that compounds over equipment lifecycles. Sensor monitoring enables operating practices and maintenance strategies that extend equipment lifespans by 20-35% while maintaining performance capabilities. Extended asset lifespans defer capital replacement costs while maximizing return on equipment investments.

Insurance cost reductions reflect the improved safety and reliability achieved through comprehensive monitoring systems. Insurance providers increasingly recognize the risk reduction benefits of predictive maintenance programs, offering premium reductions of 10-20% for companies with comprehensive monitoring capabilities. These ongoing cost reductions provide additional justification for monitoring system investments.

Future Evolution and Emerging Technologies

The trajectory of sensor technology development in construction equipment monitoring points toward even more sophisticated capabilities as underlying technologies advance and new applications emerge. Edge computing integration, artificial intelligence enhancement, and expanded sensor capabilities promise to further transform equipment monitoring and management practices.

Edge computing integration enables more sophisticated local data processing and decision-making capabilities that reduce dependence on cloud connectivity while improving system response times. Local processing capabilities support time-critical applications including safety monitoring and emergency shutdown systems that require immediate response to dangerous conditions.

Artificial intelligence advancement will enable more sophisticated pattern recognition, anomaly detection, and predictive modeling capabilities that surpass current system performance. AI-enhanced monitoring systems will recognize complex failure modes, optimize maintenance strategies, and provide increasingly accurate predictions about equipment performance and maintenance requirements.

Wireless sensor network expansion will enable monitoring of previously inaccessible equipment components while reducing installation complexity and costs. Advanced wireless protocols including 5G connectivity will support more comprehensive monitoring coverage with improved reliability and reduced infrastructure requirements.

Advanced sensor miniaturization and cost reduction will enable monitoring of smaller equipment components and lower-value assets that currently cannot justify monitoring system costs. Expanded monitoring coverage will provide more comprehensive equipment health visibility while supporting predictive maintenance strategies across entire equipment fleets.

Conclusion

Continuous performance assessment systems powered by advanced sensor technologies represent a fundamental transformation in construction equipment management that addresses the industry’s most pressing challenges through data-driven intelligence and proactive maintenance strategies. The technology’s ability to provide early warning of developing problems, optimize maintenance scheduling, and extend equipment lifespans creates unprecedented opportunities for improving construction operations while reducing costs and enhancing safety.

The construction industry’s adoption of sensor-based monitoring technologies accelerates as organizations recognize the compelling economic benefits and operational improvements achievable through comprehensive implementation. Early adopters demonstrate that sensor monitoring systems not only prevent costly equipment failures but also improve productivity, enhance safety, and optimize resource utilization across construction operations.

The future of construction equipment management lies in the intelligent integration of sensor technologies with advanced analytics and machine learning capabilities that transform traditional reactive maintenance into proactive, predictive strategies. Organizations that embrace comprehensive sensor monitoring systems today will lead the industry’s evolution toward intelligent, data-driven equipment management that redefines the standards for operational excellence and competitive advantage.