Circular Economy Approaches in Construction and Industrial Projects

The construction industry stands at the forefront of a revolutionary transformation toward circular economy in construction projects, fundamentally reimagining how resources flow through building lifecycles. This paradigm shift represents a decisive departure from traditional linear models, where materials follow a take-make-dispose trajectory, toward regenerative systems that maximize resource value while minimizing waste generation. As environmental pressures intensify and resource scarcity becomes increasingly apparent, circular economy principles offer a pathway to sustainable construction that delivers economic, environmental, and social benefits.

Understanding the Circular Economy Framework in Construction

The circular economy in construction operates on three fundamental principles: designing out waste and pollution, keeping products and materials in use, and regenerating natural systems. This approach recognizes that construction materials represent valuable resources that should remain productive throughout multiple lifecycles rather than becoming waste after a single use.

Traditional construction practices follow linear models where raw materials are extracted, processed into building components, used in construction projects, and ultimately discarded as waste. This approach generates approximately 32% of global resource consumption and accounts for roughly 75% of construction waste that could be valuable but remains unutilized due to inadequate circular economy frameworks.

Circular construction principles fundamentally alter this trajectory by implementing closed-loop systems where materials from deconstructed buildings become inputs for new construction projects. This approach extends material lifecycles, reduces demand for virgin resources, and creates economic value from materials that would otherwise require costly disposal.

Design for Disassembly and Material Recovery

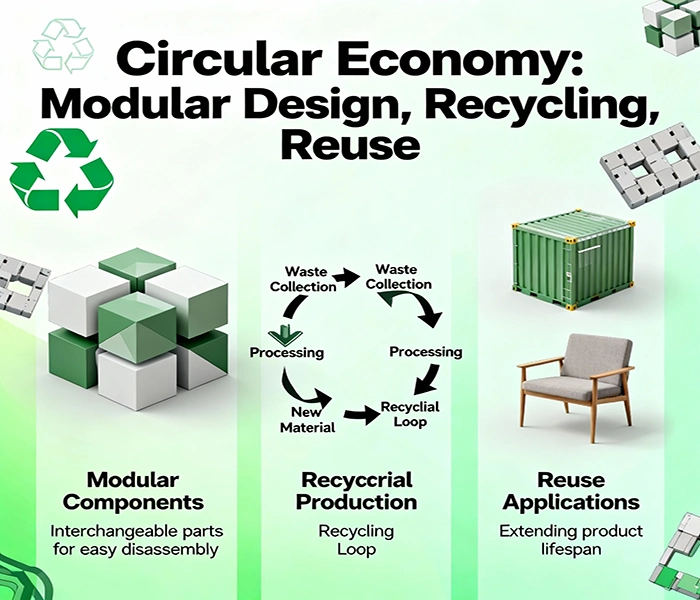

Waste reduction begins at the design stage through comprehensive planning that considers end-of-life material recovery. Design for disassembly represents a fundamental shift in architectural and engineering thinking, prioritizing material recoverability alongside traditional performance criteria such as structural integrity, aesthetic appeal, and functional efficiency.

Modular design principles facilitate disassembly by creating standardized connections, reversible joints, and component standardization that enables efficient material recovery. These approaches utilize mechanical fasteners rather than chemical adhesives, standardized dimensions that accommodate reuse in multiple applications, and material identification systems that facilitate sorting and processing.

Building information modeling (BIM) technologies support circular design by creating comprehensive material inventories that track component specifications, installation methods, and end-of-life recovery potential. These digital material passports enable informed decision-making throughout building lifecycles while facilitating efficient material recovery operations.

Material selection strategies prioritize components with high recovery potential, long service lives, and multiple reuse applications. Designers increasingly specify materials based on their circular economy potential rather than focusing exclusively on initial cost and performance characteristics.

Modular Construction and Systematic Resource Optimization

Modular construction represents perhaps the most effective implementation of circular economy principles in contemporary building practices. This approach can reduce construction waste by up to 90% compared to traditional site-built methods while creating systematized pathways for material reuse and recycling.

Factory-controlled environments enable precise material management, comprehensive waste reduction protocols, and systematic recycling processes that are difficult to achieve on traditional construction sites. Modular facilities can implement sophisticated sorting systems, material recovery protocols, and quality control measures that ensure maximum resource utilization.

Standardized component systems facilitate material interchangeability between projects, enabling components from one building to be easily incorporated into subsequent constructions. This standardization creates economies of scale for material recovery while simplifying logistics and quality assurance processes.

Prefabrication approaches reduce material waste through precise cutting, optimized material usage, and controlled inventory management. Factory environments eliminate weather-related damage, reduce theft and vandalism, and enable sophisticated lean manufacturing techniques that minimize waste generation.

Advanced Recycling and Material Processing Technologies

Recycling in construction has evolved beyond simple material sorting to encompass sophisticated processing technologies that create high-value building materials from construction waste streams. Advanced recycling processes can transform construction debris into products that meet or exceed the performance characteristics of virgin materials.

Concrete recycling technologies create high-quality aggregates through crushing, screening, and separation processes that remove contaminants while maintaining structural integrity. Recycled concrete aggregates can replace up to 100% of virgin aggregates in many applications while providing comparable performance characteristics.

Steel recycling represents one of construction’s greatest circular economy success stories, with steel maintaining its properties through unlimited recycling cycles. Advanced sorting technologies, magnetic separation, and metallurgical processing create recycled steel products that are indistinguishable from virgin materials.

Wood waste processing transforms construction timber into engineered wood products, biomass fuel, and other value-added applications. Advanced processing techniques can recover high-quality lumber from demolition projects while processing lower-grade materials into particle board, mulch, and energy generation feedstock.

Gypsum recycling processes separate drywall from other construction materials and process it into new gypsum products. These closed-loop systems can incorporate recycled gypsum at percentages exceeding 25% while maintaining product quality and performance standards.

Technological Innovation in Circular Construction

Digital technologies increasingly support circular economy implementation through material tracking, optimization algorithms, and automated systems that maximize resource efficiency. Internet of Things (IoT) sensors embedded in building materials enable real-time monitoring of component conditions, facilitating predictive maintenance and optimal end-of-life timing.

Artificial intelligence applications optimize material selection, deconstruction planning, and resource allocation based on comprehensive lifecycle analysis. Machine learning algorithms can identify optimal material recovery strategies while predicting market demand for specific recycled materials.

Blockchain technologies create immutable material provenance records that track component histories, performance characteristics, and environmental impacts throughout multiple lifecycles. These systems enable transparency and trust in circular material markets while facilitating quality assurance and regulatory compliance.

Robotics applications automate material sorting, disassembly operations, and quality assessment processes that would be labor-intensive or dangerous for human workers. Advanced robotics can identify material types, assess quality conditions, and execute precise disassembly operations that maximize material recovery rates.

Economic Models for Circular Construction

Sustainable construction requires viable economic models that create financial incentives for circular economy adoption. Material-as-a-service models enable building owners to access high-quality materials without ownership obligations, creating business cases for manufacturers to design for durability and recoverability.

Extended producer responsibility frameworks require material manufacturers to accept responsibility for end-of-life management, creating incentives for designing products with circular economy principles. These systems internalize disposal costs while creating revenue streams from material recovery operations.

Carbon accounting systems that recognize the environmental benefits of material reuse and recycling create economic value for circular construction practices. Carbon credit mechanisms can provide financial returns for projects that demonstrate quantifiable environmental benefits through circular economy implementation.

Collaborative consumption models enable material sharing between projects, reducing inventory costs while maximizing resource utilization. Digital platforms facilitate material exchanges, enabling project teams to identify available materials while creating markets for surplus construction resources.

Regional Implementation and Policy Framework

Successful circular economy implementation requires supportive policy frameworks that create regulatory incentives while removing barriers to material reuse and recycling. Building codes increasingly recognize recycled materials and modular construction approaches while maintaining safety and performance standards.

Procurement policies that prioritize circular economy criteria in public construction projects create market demand for sustainable practices while demonstrating feasibility and economic viability. These policies can specify recycled content requirements, end-of-life planning, and circular economy performance metrics.

Waste disposal regulations that increase landfill costs while providing incentives for material recovery create economic drivers for circular economy adoption. Extended producer responsibility requirements and material recovery mandates support comprehensive circular economy implementation.

Regional material exchanges and processing facilities create infrastructure necessary for efficient circular economy operations. These systems require coordination between public and private stakeholders to ensure adequate capacity and geographic coverage.

Performance Measurement and Continuous Improvement

Circular economy implementation requires comprehensive performance measurement systems that track material flows, waste reduction, and environmental impacts throughout project lifecycles. Key performance indicators include material recovery rates, waste diversion percentages, and lifecycle carbon emissions.

Lifecycle assessment methodologies evaluate the comprehensive environmental impacts of circular construction practices, enabling comparison with traditional approaches and identification of optimization opportunities. These assessments consider resource extraction, processing, transportation, construction, operation, and end-of-life impacts.

Certification systems provide third-party verification of circular economy performance while creating market recognition for sustainable practices. These systems establish standardized criteria for circular construction while enabling comparative assessment of different approaches.

Continuous improvement protocols enable systematic refinement of circular economy practices based on performance data and emerging technologies. These systems facilitate knowledge sharing, best practice development, and technology advancement that accelerate circular economy adoption.

Future Trajectories and Innovation Opportunities

The evolution of circular economy approaches in construction points toward increasingly sophisticated integration of digital technologies, advanced materials, and systemic approaches that transform entire construction ecosystems. Artificial intelligence applications will optimize material flows while biotechnology creates new categories of biodegradable construction materials.

Urban mining concepts recognize existing built environments as material repositories that can be systematically harvested to supply future construction projects. This approach requires sophisticated material assessment, recovery planning, and processing capabilities that transform demolition into resource generation.

The integration of circular economy principles with smart city development creates opportunities for systematic resource optimization across entire urban systems. These approaches coordinate material flows between multiple construction projects while optimizing transportation, processing, and storage operations.

Circular economy approaches in construction and industrial projects represent more than environmental responsibility—they embody a fundamental transformation toward resource efficiency, economic optimization, and systemic sustainability. Through comprehensive implementation of circular principles, the construction industry can create regenerative systems that deliver superior environmental performance while maintaining economic competitiveness. This transformation ensures that today’s construction activities contribute to rather than detract from long-term environmental and economic sustainability, creating a foundation for resilient communities and prosperous economies.