Concrete has been the backbone of construction for centuries, revered for its durability, versatility, and cost-effectiveness. Over the past few years, some revolutionary developments have come forward that have created breakthroughs in construction design and functionality. These innovations not only solve long-term issues like environmental impact and durability but also create new opportunities for designing smarter, more sustainable, and more resilient buildings.

Looking ahead to 2030, the path of concrete innovation is going to transform the sector, aligning it with the goals of efficiency, sustainability, and human safety.

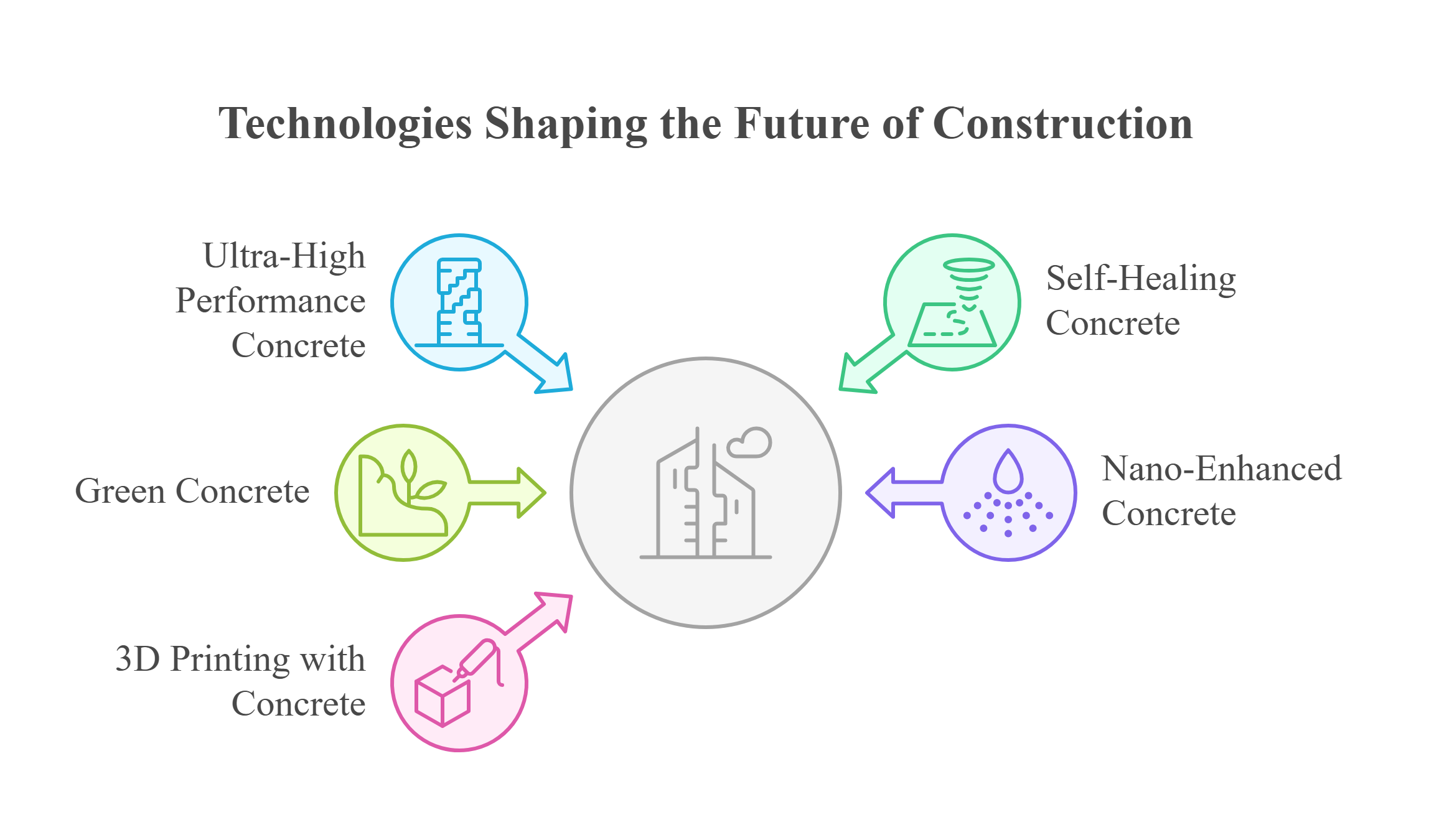

Concrete Technologies Shaping Future of Construction

Ultra-High-Performance Concrete (UHPC)

Ultra-High-Performance Concrete (UHPC)

Ultra-High-Performance Concrete (UHPC) is exemplary in terms of materials innovation. Specializing in high strength, high durability, and attractive appearance, UHPC is a composite material consisting of fine-grained cement, silica fume, steel fibers, and other modern admixtures.

The primary advantage of UHPC is that it can achieve compressive strengths greater than 150 MPa, which is 3-5 times stronger than ordinary concrete, which means that we can develop slender, light structural members and reduce total material volume and carbon footprint. UHPC is also highly resistant to environmental degradation, including freeze-thaw attack, chemical attack, and abrasion, making it appropriate for infrastructure built in harsh environments. As studies improve, the price of UHPC drops further, which makes it more suitable for mass application. Industry expectations predict a dramatic increase in the use of UHPC in the coming decade based on its improved performance and sustainability advantages.

-

Self-Healing Concrete

Crack formation has long been one of the greatest challenges in concrete durability, and the subsequent water ingress and corrosion of reinforced steel. Self-healing concrete is an innovative system designed to heal cracks as they occur, which greatly extends the service life of all structures. This product has encapsulated healing agents or bacteria that activate when cracks develop. These agents will react with water and air to generate new mineral compounds that seal and fill the cracks. For example, bacteria encapsulated in concrete technologies shaping construction can form limestone, thereby sealing fissures. Alternatively, microcapsules releasing healing agents on crack development activate process of crack repair.

The development of self-healing concrete furthers sustainability goals via reduced maintenance costs, less consumption of resources, and longer service life of structures. The technology is developing quickly, with industry expectations for its widespread use in infrastructures such as roads, tunnels, and buildings in the late 2020s.

With self-healing concrete’s ability to maintain integrity in difficult environments, it serves as a foundation of sustainable infrastructure simply in seismic areas or regions with severe environmental conditions.

-

Green and Carbon-Reduced Concrete

Environmental concerns are pressing the construction industry toward sustainable solutions. Green concrete is a term used to describe formulations that are specifically created to minimize carbon emissions and environmental footprint. Some of the innovations involve the use of supplementary cementitious materials (SCMs), recycled aggregates, and new binders that drastically reduce cement content or substitute it entirely.

One of the most exciting breakthroughs is the introduction of carbon-capturing concrete, which deploys CO2 mineralization during the curing process. This tech captures atmospheric CO2 in the concrete matrix, creating “carbon-negative” concrete. The trapped carbon, aside from lowering the material’s overall carbon score, can even enhance mechanical properties in certain formulations.

Besides, scientists are also looking into bio-concrete that employs bacteria or vegetative material to aggregate bind and still cut down on the use of conventional cement. Market forecasts suggest that green concrete will make up a large percentage of new building materials by 2030 due to regulatory demands and customer pressure for environmentally friendly buildings.

-

Nano-Enhanced Concrete

Nanotechnology is extending the limits of concrete performance by offering unprecedented control at the microstructural level. Nano-enhanced concrete is a composite material that consists of existing concrete plus nano-materials such as nano-silica, carbon nanotubes or graphene for example, which exponentially increase properties such as strength and durability, and other functional properties.

For example, nano-silica included in the mix acts as a pozzolanic material, which refines the pore structure and increases density. Increased density means strength; therefore, concrete will achieve a compressive strength increase, a better and more safe resistance to chemical attack, resistance to freezing and thawing, and improved fatigue life. Although the typical carbon nanotube or graphene additive provides a tremendous increase in strength, it has also shown conduction properties with very slight amounts that can eventually led to self-sensing concrete which can pick up strain, cracks or deterioration.

The application of nanomaterials can also improve the sustainability aspects of concrete by reducing material requirements due to enhanced strength. Industry forecasts suggest massive growth in nano-enhanced concrete use by 2030, especially in high-performance structural applications and smart infrastructure.

-

3D Printing with Concrete

3D printing technology is generating a lot of interest within the construction industry, and concrete technologies shaping construction has been featured heavily as a base material. Additive manufacturing allows for the production of geometries and dimensions that would be very difficult or impossible using conventional building methods. Concrete 3D printing is the layer-by-layer construction of a uniquely designed special concrete mixture which gives speed in construction while minimizing waste. This method has the opportunity to vastly reduce the time to construct, decrease labor costs and allow for massively unique designs. Perhaps most importantly, it supports sustainability through efficient use of materials and on-site construction, reducing transportation emissions.

New formulations today include quick-setting and self-compacting qualities, essential to the success of large-scale 3D printed structures. Further, integrated sensors in printed structures make possible continuous health monitoring, echoing the emerging trend of smart infrastructure.

Market analysts see the implementation of 3D printing in high-profile infrastructure projects in urban landscapes speeding ahead through 2025, transforming the way structures are designed, constructed, and maintained.

The Future of Concrete: Innovations on the Horizon

The future direction of concrete technologies shaping construction is towards more intelligent, sustainable, and efficient material. The intersection of nanotechnology, additive manufacturing, and environmental science presages a future where concrete will not just be stronger and longer lasting but will even positively contribute to the sustainability of the environment.

New ideas like AI-based mix design, which uses big data and machine learning to optimize material formulations, are already in pilot stages. They have the potential to tailor concrete properties for given applications more finely than ever before, cutting waste, costs, and emissions even more.

In the next ten years, regulation and industry norms will move towards highlighting sustainability measures, durability standards, and intelligent features. The construction sector will thus witness a changeover towards increasingly adaptive and performance-based materials.

Conclusion: Building the Future with Innovative Concrete

Concrete continues to be a basic material in our built environment. However, with the increasing pressure to construct more intelligent, sustainable, and resilient buildings, the sector needs to welcome the latest technologies revolutionizing conventional concrete.

From ultra-high-performance versions and self-healing systems to ecologically sustainable designs, these innovations are leading the way towards a new world. Nanotechnology and additive manufacturing both improve the mechanical properties of the concrete but also augment novel and sustainable architectural opportunities.

As we move forward in this period of rapid discoveries, it will be essential to collaborate with material scientists, engineers, urban planners, and construction organisations. Forward-thinking concrete innovations today, in ways that are intelligent and sustainable, beginning in 2030 and beyond, will be responsible for the strength, beauty, and innovation in the architectural ideas of tomorrow.