Automation and Robotics Transforming Construction Productivity

The construction industry stands at the precipice of a technological revolution where automation and robotics in construction are fundamentally transforming how buildings and infrastructure are designed, constructed, and delivered. This technological paradigm shift addresses persistent industry challenges including labor shortages, safety concerns, productivity gaps, and quality inconsistencies that have plagued construction for decades. As we advance through 2025, robotic systems and automated technologies are evolving from experimental novelties to essential tools that deliver tangible improvements in efficiency, safety, and economic performance.

The Imperative for Construction Automation

Construction automation addresses critical industry challenges that traditional methods struggle to resolve. The construction sector faces an unprecedented labor shortage, with aging workforces and declining interest among younger generations in traditional construction careers. This demographic shift creates opportunities for robotic systems to fill capability gaps while enabling skilled workers to focus on higher-value activities requiring human judgment and creativity.

Safety considerations drive automation adoption as construction remains among the most dangerous industries globally. Robotics in construction can eliminate human exposure to hazardous conditions including working at heights, handling toxic materials, and operating in unstable environments. Automated systems never experience fatigue, distraction, or human error, contributing to consistent safety performance throughout project lifecycles.

Productivity improvements through automation address the construction industry’s historical lag behind other sectors in adopting efficiency-enhancing technologies. While manufacturing industries achieved dramatic productivity gains through automation, construction productivity has remained relatively stagnant. Robotic systems operate continuously without breaks, maintain consistent quality standards, and execute repetitive tasks with precision that exceeds human capabilities.

Advanced Robotic Systems in Construction Operations

Smart construction technology encompasses diverse robotic applications that span entire construction workflows from site preparation through final finishing. Autonomous excavation systems utilize GPS guidance, LiDAR scanning, and machine learning algorithms to execute precise earthmoving operations with minimal human oversight. These systems can operate continuously while maintaining centimeter-level accuracy in material placement and site preparation.

Bricklaying robots represent breakthrough applications where mechanical precision enhances both speed and quality compared to traditional manual methods. Advanced bricklaying systems can place thousands of bricks per day while maintaining perfect alignment, consistent mortar application, and optimal structural integrity. These systems integrate seamlessly with building information modeling (BIM) systems to follow precise construction plans automatically.

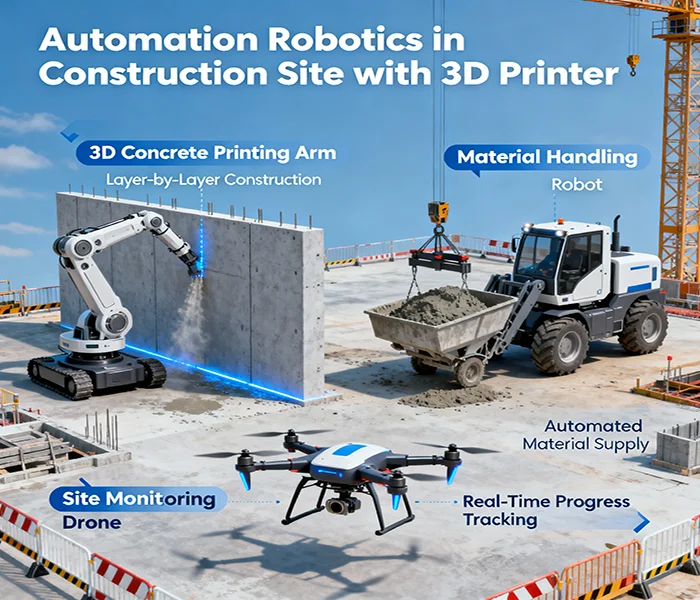

Concrete printing robots revolutionize structural construction through additive manufacturing techniques that create complex geometric forms impossible to achieve through traditional methods. 3D printing construction applications range from small architectural elements to entire building structures, enabling mass customization while reducing material waste and construction timeframes dramatically.

Robotic finishing systems automate surface preparation, painting, and detail work that traditionally requires significant manual labor. Advanced painting robots utilize computer vision to identify surface irregularities while applying consistent coating thickness and finish quality across large surface areas. These systems operate in hazardous environments while delivering superior finish quality.

Autonomous Equipment and Heavy Machinery

Autonomous machinery transforms how heavy construction equipment operates on job sites through sophisticated sensor networks, artificial intelligence, and real-time decision-making capabilities. Autonomous bulldozers, excavators, and compaction equipment execute site preparation tasks with precision that exceeds human operators while operating safely in complex environments.

GPS-guided grading systems achieve millimeter-level accuracy in site preparation while automatically adjusting for design specifications and environmental conditions. These systems utilize real-time kinematic (RTK) positioning technology integrated with 3D design models to create perfectly graded surfaces that require minimal rework or correction.

Autonomous hauling systems coordinate material transport across construction sites using self-driving trucks and coordinated logistics algorithms. These systems optimize route planning, reduce cycle times, and eliminate safety risks associated with heavy vehicle operations in congested construction environments.

Load monitoring and optimization systems embedded in autonomous equipment ensure optimal machine utilization while preventing overloading and mechanical stress. Advanced telemetrics provide real-time equipment health monitoring that enables predictive maintenance and minimizes unplanned downtime.

3D Printing and Additive Manufacturing

3D printing construction technologies represent perhaps the most transformative automation applications in contemporary building practices. Large-scale 3D printers capable of constructing entire building elements enable rapid prototyping, mass customization, and complex geometric forms that would be prohibitively expensive using traditional construction methods.

Concrete 3D printing systems utilize specialized cement mixtures optimized for additive manufacturing processes. These systems can create structural elements with integrated utilities, complex internal geometries, and optimized material distribution that reduces weight while maintaining structural performance. Advanced concrete printing enables construction of buildings in remote locations where traditional construction resources are unavailable.

Metal 3D printing applications create structural connections, architectural elements, and specialized components with precision and complexity impossible through traditional fabrication methods. These systems enable just-in-time manufacturing that reduces inventory requirements while enabling rapid response to design changes and custom requirements.

Multi-material 3D printing systems integrate different materials within single components, creating elements with optimized properties for specific applications. These systems can embed utilities, sensors, and functional elements during the printing process, reducing assembly requirements and improving system integration.

Artificial Intelligence and Machine Learning Integration

Smart construction projects increasingly incorporate artificial intelligence and machine learning systems that optimize robotic operations, predict maintenance requirements, and adapt to changing site conditions automatically. Machine learning algorithms analyze vast quantities of construction data to identify optimization opportunities and predict potential problems before they occur.

Computer vision systems enable robots to navigate complex construction environments while identifying obstacles, hazards, and quality issues automatically. Advanced image recognition algorithms can detect structural defects, verify construction compliance, and guide robotic operations with human-level visual interpretation capabilities.

Predictive analytics applications optimize construction schedules, resource allocation, and equipment deployment based on historical performance data and real-time site conditions. These systems enable proactive management strategies that prevent delays while maximizing resource utilization efficiency.

Natural language processing interfaces enable construction workers to interact with robotic systems using voice commands and conversational interfaces, reducing training requirements while improving system accessibility for non-technical users.

Collaborative Human-Robot Workflows

The integration of robotics in construction creates collaborative workflows where human expertise combines with robotic precision to achieve superior results. Rather than replacing human workers, construction robots augment human capabilities while eliminating dangerous and repetitive tasks that contribute to worker fatigue and injury.

Collaborative robotic arms (cobots) work alongside human operators in tasks requiring both precision and judgment. These systems can handle heavy lifting, precise positioning, and repetitive operations while human workers focus on quality assessment, problem-solving, and complex assembly operations.

Augmented reality interfaces enable construction workers to supervise and control robotic operations through intuitive visual overlays that display robot status, task progress, and operational parameters. These systems enable skilled workers to manage multiple robotic systems simultaneously while maintaining quality oversight.

Training and certification programs ensure construction workers develop skills necessary to operate and maintain robotic systems effectively. These programs create career advancement opportunities while ensuring successful human-robot collaboration in construction environments.

Quality Control and Inspection Automation

Automated quality control systems utilize advanced sensors, computer vision, and measurement technologies to verify construction compliance with specifications and building codes. These systems provide objective, consistent quality assessment that reduces subjective interpretation while creating comprehensive documentation for compliance verification.

Drone-based inspection systems provide comprehensive site monitoring, progress tracking, and quality assessment capabilities. High-resolution imaging, thermal sensors, and LiDAR scanning create detailed documentation of construction progress while identifying potential quality issues and safety hazards.

Laser scanning and photogrammetry systems create precise as-built documentation that verifies construction compliance with design specifications. These systems generate millimeter-accurate measurements that exceed traditional surveying capabilities while creating permanent records for facility management applications.

Automated material testing systems verify concrete strength, steel properties, and other material characteristics without human intervention. These systems provide real-time quality assurance that enables immediate corrective action when materials fail to meet specifications.

Economic Impact and Return on Investment

The economic case for construction automation extends beyond direct labor savings to encompass improved quality, reduced rework, enhanced safety performance, and accelerated project delivery. While initial investments in robotic systems require substantial capital, the long-term benefits typically justify automation investments through improved productivity and reduced operational costs.

Labor cost reductions through automation become increasingly significant as skilled labor costs continue rising while robotic system costs decline. Robotic systems operate without benefits, overtime, or productivity variations, providing predictable cost structures that improve project financial performance.

Risk reduction benefits include decreased insurance costs, reduced safety incidents, and minimized rework requirements. Robotic systems eliminate human error factors while providing consistent performance that reduces project risk and uncertainty.

Competitive advantages for construction companies adopting automation include improved project delivery capabilities, enhanced quality reputation, and ability to undertake projects that would be challenging using traditional methods. Early automation adopters position themselves advantageously in increasingly competitive construction markets.

Future Integration and Scalability

The trajectory of automation and robotics in construction points toward increasingly sophisticated systems that integrate multiple robotic applications within coordinated workflows. Future construction sites will feature fleets of specialized robots operating under centralized control systems that optimize overall project performance.

Modular robotic systems enable scalable automation deployment based on project requirements and budget constraints. These systems allow construction companies to implement automation gradually while building internal capabilities and demonstrating value before expanding robotic applications.

Integration with smart city infrastructure creates opportunities for construction robots to contribute to urban management systems through data sharing, coordinated operations, and integrated service delivery. These connections enable construction activities to support broader urban optimization objectives.

International standardization efforts ensure robotic systems operate safely and effectively across different regulatory environments while enabling technology transfer and best practice sharing among global construction markets.

Automation and robotics are transforming construction productivity through systematic replacement of manual processes with precision-controlled, intelligent systems that operate safely and efficiently. This transformation represents more than technological upgrading—it embodies a fundamental reimagining of construction workflows that leverages human creativity and robotic precision to create superior building outcomes. As these technologies mature and become increasingly accessible, construction automation will transition from competitive advantage to industry standard, creating safer, more efficient, and more sustainable construction practices that benefit workers, owners, and society.