AI-Powered Hazard Detection on Construction Sites and its Benefits

The construction industry faces an unprecedented safety crisis, with workplace fatalities and injuries continuing to plague job sites worldwide. In 2022 alone, the U.S. construction sector recorded 1,069 worker deaths, representing over 21% of all workplace fatalities despite employing only 7% of the workforce. Against this sobering backdrop, AI hazard detection systems emerge as revolutionary tools that promise to transform construction safety from reactive protocols to proactive, intelligent protection mechanisms that safeguard workers before incidents occur.

Understanding AI-Powered Hazard Detection Technology

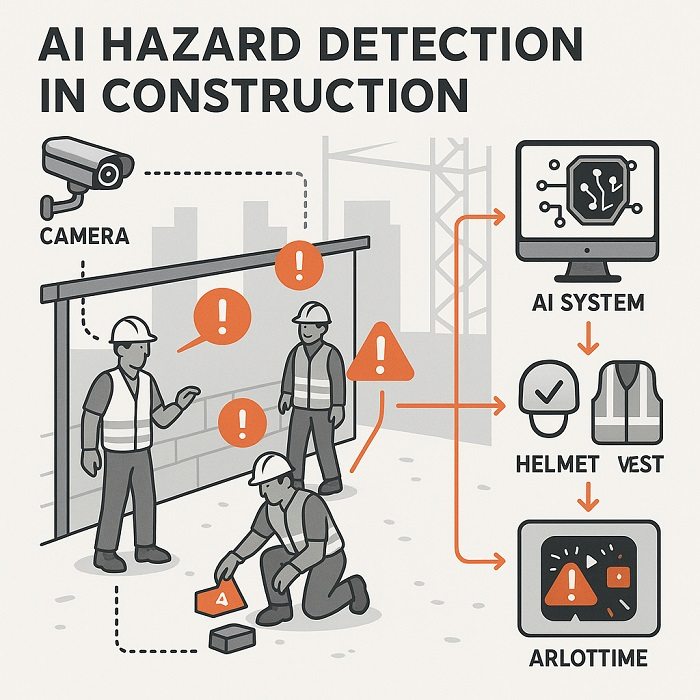

Artificial intelligence in construction safety represents a paradigm shift from traditional human-dependent monitoring to sophisticated automated systems capable of continuous surveillance, pattern recognition, and predictive analysis. AI hazard detection systems leverage advanced computer vision, machine learning algorithms, and real-time data processing to identify potential safety risks with unprecedented accuracy and speed.

The global AI in construction market demonstrates explosive growth potential, expanding from USD 2.5 billion in 2022 to a projected USD 15.1 billion by 2032, with safety applications driving significant adoption rates. This remarkable growth trajectory reflects industry recognition that traditional safety measures, while essential, often rely on human vigilance that can be prone to errors, fatigue, and limited coverage across large construction sites.

Modern AI safety systems integrate multiple technologies including high-definition cameras, thermal sensors, LiDAR systems, and wearable devices to create comprehensive monitoring networks that observe every aspect of construction operations. Machine learning algorithms trained on millions of construction site images can instantly recognize safety violations, equipment malfunctions, and hazardous conditions that might escape human observation.

The sophistication of these systems extends beyond simple object detection to include behavioral analysis, environmental monitoring, and predictive risk assessment. Advanced AI platforms can distinguish between normal construction activities and potentially dangerous situations, automatically generating alerts when workers enter hazardous zones, operate equipment unsafely, or fail to comply with safety protocols.

Real-Time Hazard Identification and Alert Systems

The cornerstone of effective AI hazard detection systems lies in their ability to identify and respond to safety threats in real time. Computer vision algorithms continuously analyze video feeds from construction sites, processing thousands of frames per second to detect unsafe conditions, non-compliance with safety protocols, and emerging hazards before they result in incidents.

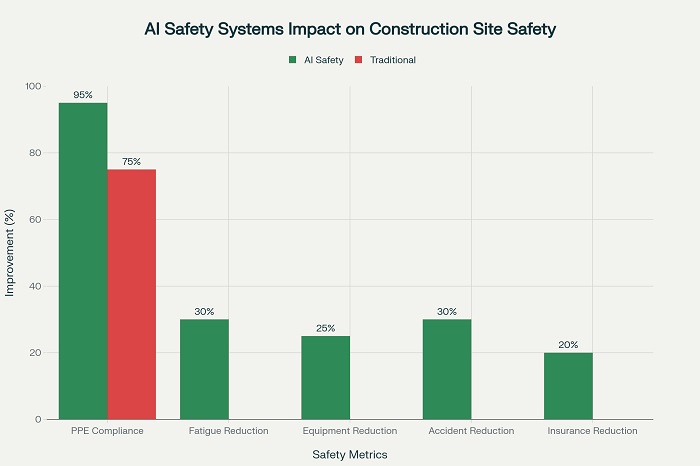

Personal Protective Equipment (PPE) compliance monitoring represents one of the most immediate and impactful applications of AI safety technology. Systems can automatically identify workers not wearing required safety helmets, high-visibility vests, safety harnesses, or protective eyewear, instantly alerting supervisors to non-compliance situations. Studies indicate that sites implementing AI-powered PPE monitoring achieve compliance rates exceeding 95%, compared to 70-80% with traditional human-based oversight.

Proximity detection and collision avoidance capabilities provide another critical layer of protection through AI systems that monitor the spatial relationships between workers, heavy equipment, and hazardous areas. When workers approach dangerous zones near operating machinery, excavation sites, or overhead work areas, the system automatically generates warnings to both workers and equipment operators, significantly reducing collision risks.

Environmental hazard detection encompasses monitoring for unsafe working conditions including exposure to hazardous gases, excessive noise levels, extreme temperatures, and unstable structures. AI systems continuously analyze environmental data from distributed sensor networks, providing immediate alerts when conditions exceed safe operating parameters. This proactive monitoring prevents exposure-related injuries and ensures compliance with occupational safety regulations.

Fall prevention represents a particularly crucial application area, as falls account for the largest percentage of construction fatalities. AI systems monitor worker movements near edges, openings, and elevated surfaces, automatically detecting precarious positions and unsafe behaviors that could lead to falls. Advanced algorithms can even predict potential fall scenarios based on worker positioning and movement patterns.

Behavioral Analysis and Risk Assessment

AI hazard detection systems excel in analyzing worker behavior patterns to identify risk factors that traditional safety monitoring might overlook. Machine learning algorithms trained on extensive datasets of construction activities can recognize subtle indicators of fatigue, distraction, or unsafe working practices that increase accident probability.

Fatigue detection through computer vision analysis monitors worker movements, posture, and activity levels to identify signs of exhaustion that could impair judgment or reaction times. Studies demonstrate that construction sites implementing AI-powered fatigue monitoring systems achieve up to 30% reductions in fatigue-related incidents, as supervisors can intervene early to provide rest periods or task reassignments.

Unsafe behavior pattern recognition enables AI systems to identify workers engaging in risky practices such as taking shortcuts, bypassing safety procedures, or operating equipment incorrectly. The systems learn from observing normal safe working patterns and flag deviations that could indicate dangerous practices. This capability enables targeted safety training and interventions focused on specific behavioral risks.

Predictive risk modeling combines behavioral analysis with environmental factors, equipment status, and historical incident data to calculate dynamic risk scores for different areas and activities within construction sites. These risk assessments enable safety managers to allocate resources proactively, adjusting staffing levels and implementing additional safety measures in high-risk areas before incidents occur.

The integration of wearable technology with AI analysis platforms provides additional layers of behavioral monitoring through physiological indicators including heart rate, body temperature, and stress levels. This comprehensive approach to worker monitoring enables early detection of health issues that could compromise safety while maintaining worker privacy and comfort.

Predictive Maintenance and Equipment Safety

Equipment-related incidents represent a significant source of construction site injuries and fatalities. AI hazard detection systems address this challenge through sophisticated predictive maintenance capabilities that identify potential equipment failures before they create dangerous situations.

Machine learning algorithms analyze operational data from construction equipment including vibration patterns, temperature readings, hydraulic pressure levels, and performance metrics to predict component failures and maintenance requirements. This proactive approach reduces equipment-related accidents by up to 25% while extending machinery lifespans and improving operational efficiency.

Automated equipment inspection capabilities leverage computer vision to identify visible defects, wear patterns, and safety hazards on construction equipment. AI systems can detect cracked components, hydraulic leaks, worn tires, and other conditions that could lead to equipment failures or accidents. These automated inspections supplement human inspections while providing consistent, objective assessments.

Real-time equipment monitoring during operations enables AI systems to detect abnormal operating conditions that could pose safety risks. Systems monitor factors such as excessive vibration, overheating, hydraulic system pressures, and load capacities, automatically shutting down equipment when dangerous conditions are detected. This immediate response capability prevents catastrophic failures that could endanger workers.

Integration with equipment management systems enables AI platforms to track maintenance schedules, inspection records, and operational histories to optimize safety-focused maintenance planning. Predictive algorithms consider usage patterns, environmental conditions, and component wear rates to schedule maintenance activities that maximize safety while minimizing operational disruptions.

Comprehensive Safety Analytics and Reporting

The data-driven approach of AI hazard detection systems generates comprehensive safety analytics that enable construction organizations to understand risk patterns, optimize safety protocols, and demonstrate compliance with regulatory requirements. Advanced analytics platforms process millions of safety observations to identify trends, correlations, and optimization opportunities.

Incident prediction modeling uses historical safety data combined with current site conditions to forecast potential accident scenarios. These predictive capabilities enable safety managers to implement preventive measures in high-risk situations, significantly reducing incident rates. Organizations implementing comprehensive incident prediction report 20-40% reductions in workplace accidents within the first year of deployment.

Safety performance dashboards provide real-time visibility into key safety metrics including compliance rates, incident frequencies, near-miss events, and risk levels across different work areas. These dashboards enable immediate identification of safety trends and rapid response to emerging risks while supporting data-driven safety management decisions.

Automated compliance reporting streamlines the documentation required for regulatory compliance and insurance purposes. AI systems automatically generate comprehensive safety reports that include incident documentation, compliance verification, and corrective action tracking. This automated reporting reduces administrative overhead while ensuring accurate, complete safety documentation.

Root cause analysis capabilities enable AI systems to analyze incident patterns and identify underlying factors that contribute to safety risks. By examining correlations between environmental conditions, work activities, equipment usage, and incident occurrences, AI platforms provide insights that support targeted safety improvements and risk mitigation strategies.

Integration with Construction Management Systems

The effectiveness of AI hazard detection systems multiplies when integrated with broader construction management platforms, creating comprehensive ecosystems that coordinate safety management with project planning, resource allocation, and operational optimization.

Building Information Modeling (BIM) integration enables AI safety systems to understand spatial relationships, planned activities, and potential hazard areas based on construction designs. This integration allows for predictive safety planning that identifies potential risks during the design phase and implements preventive measures before construction begins.

Project scheduling integration coordinates safety monitoring with planned construction activities, enabling AI systems to anticipate high-risk periods and implement enhanced safety measures accordingly. When dangerous activities such as crane operations, concrete pours, or electrical work are scheduled, the system automatically increases monitoring intensity and implements additional safety protocols.

Resource management coordination ensures that safety personnel and equipment are deployed optimally based on AI-generated risk assessments. When AI systems identify elevated risk levels in specific areas, they can automatically trigger deployment of additional safety resources, ensuring adequate coverage during high-risk activities.

Communication platform integration enables AI safety systems to distribute alerts and safety information through established communication channels including mobile applications, digital displays, and wearable devices. This comprehensive communication approach ensures that safety information reaches all relevant personnel immediately when hazards are detected.

Economic Benefits and Return on Investment

The implementation of AI hazard detection systems delivers substantial economic benefits that extend far beyond safety improvements to encompass productivity gains, cost reductions, and improved project outcomes. Organizations implementing comprehensive AI safety solutions typically achieve return on investment within 6-18 months through multiple value streams.

Accident reduction directly translates into significant cost savings through reduced medical expenses, workers’ compensation claims, project delays, and regulatory penalties. Companies implementing AI safety systems report average incident cost reductions of 40-60% within the first year, with some organizations achieving even greater savings through comprehensive risk mitigation.

Insurance cost reductions represent another significant economic benefit, as insurers increasingly offer premium discounts for organizations demonstrating advanced safety management capabilities through AI systems. Companies with comprehensive AI safety implementations report insurance premium reductions of 15-25%, providing ongoing cost savings throughout policy periods.

Productivity improvements result from reduced work stoppages, fewer safety-related delays, and improved worker confidence in safe working environments. Organizations report productivity gains of 10-20% when comprehensive AI safety systems eliminate safety-related disruptions and enable continuous construction progress.

Regulatory compliance benefits include reduced inspection times, fewer violations, and improved relationships with regulatory authorities. Automated compliance documentation and proactive risk management significantly reduce the administrative burden associated with safety compliance while demonstrating corporate commitment to worker protection.

Overcoming Implementation Challenges

The deployment of AI hazard detection systems faces several challenges that organizations must address strategically to achieve successful implementation and maximum benefit realization. Privacy concerns represent a significant consideration as comprehensive monitoring systems capture detailed information about worker activities and behaviors.

Data security requirements necessitate robust cybersecurity frameworks that protect sensitive safety and operational data from unauthorized access or cyber threats. Organizations must implement comprehensive security measures including encryption, access controls, and monitoring systems to protect AI safety platforms from potential vulnerabilities.

Integration complexity can pose challenges when connecting AI safety systems with existing construction management platforms, equipment systems, and communication networks. Successful implementations require careful planning, system compatibility assessment, and often custom integration development to achieve seamless operation.

Change management represents a crucial success factor as construction teams adapt to AI-enhanced safety protocols and monitoring systems. Organizations must invest in training programs, communication strategies, and cultural change initiatives to ensure workforce acceptance and effective utilization of AI safety capabilities.

Cost considerations influence adoption decisions, particularly for smaller construction organizations with limited capital resources. However, the rapid payback periods demonstrated through safety improvements, cost reductions, and productivity gains make AI safety systems increasingly accessible through financing options and service-based models.

Future Evolution and Emerging Capabilities

The development trajectory of AI hazard detection systems points toward even more sophisticated capabilities as underlying technologies continue advancing and integration with other emerging technologies creates new possibilities for construction safety management.

Edge computing integration reduces dependence on cloud connectivity while improving system response times for time-critical safety applications. Local processing capabilities ensure that essential safety functions continue operating even when external connectivity is compromised, maintaining protection in remote or challenging construction environments.

Augmented reality integration with AI safety systems enables immersive safety training, real-time hazard visualization, and enhanced situational awareness for construction workers. AR interfaces can display safety information, hazard alerts, and procedural guidance directly in workers’ fields of view, improving safety compliance and decision-making.

Autonomous system coordination represents an emerging frontier where AI safety platforms coordinate with autonomous construction equipment, drones, and robotic systems to create comprehensive safety ecosystems. These integrated systems can automatically adjust autonomous operations based on worker proximity, safety conditions, and risk assessments.

Quantum computing applications may eventually enable unprecedented data processing capabilities that support real-time optimization of complex safety scenarios with millions of variables and constraints, creating new possibilities for predictive safety management.

Conclusion

AI hazard detection systems represent a transformative advancement in construction safety management that addresses the industry’s most pressing challenges through proactive, intelligent monitoring and risk mitigation capabilities. The technology’s ability to continuously observe, analyze, and respond to safety threats provides unprecedented protection for construction workers while delivering substantial economic benefits through reduced incidents, improved compliance, and enhanced operational efficiency.

The construction industry’s adoption of AI safety technologies accelerates as organizations recognize the compelling benefits and rapid return on investment achievable through comprehensive implementation. Early adopters demonstrate that AI-powered safety systems not only protect workers but also improve project outcomes, reduce costs, and enhance competitive positioning in an increasingly safety-conscious marketplace.

The future of construction safety lies in the intelligent integration of AI technologies that transform traditional reactive safety management into proactive, predictive protection systems. Organizations that embrace comprehensive AI hazard detection capabilities today will lead the industry’s evolution toward safer, more efficient, and more profitable construction operations while setting new standards for worker protection and operational excellence.