Sustainable Materials Shaping the Future of Industrial Construction

The global construction industry stands at a critical juncture where environmental responsibility and industrial efficiency must converge. As climate change concerns intensify and resource scarcity becomes increasingly apparent, sustainable materials in industrial construction have emerged as the cornerstone of next-generation building practices. This transformation represents more than just an environmental initiative—it signifies a fundamental shift in how industrial projects are conceived, executed, and maintained throughout their lifecycle.

The Imperative for Sustainable Construction Materials

Industrial construction has traditionally relied on resource-intensive materials that contribute significantly to global carbon emissions. The construction sector accounts for approximately 39% of global carbon emissions, with cement production alone responsible for 8% of worldwide CO2 emissions. This environmental impact has catalyzed an unprecedented drive toward sustainable materials that can deliver comparable performance while dramatically reducing ecological footprint.

The transition to sustainable construction materials addresses multiple challenges simultaneously. Beyond environmental concerns, these materials often provide superior performance characteristics, enhanced durability, and improved cost-effectiveness over the building lifecycle. Industrial facilities utilizing sustainable materials frequently demonstrate better energy efficiency, reduced maintenance requirements, and enhanced occupant health and safety profiles.

Revolutionary Low-Carbon Cement Technologies

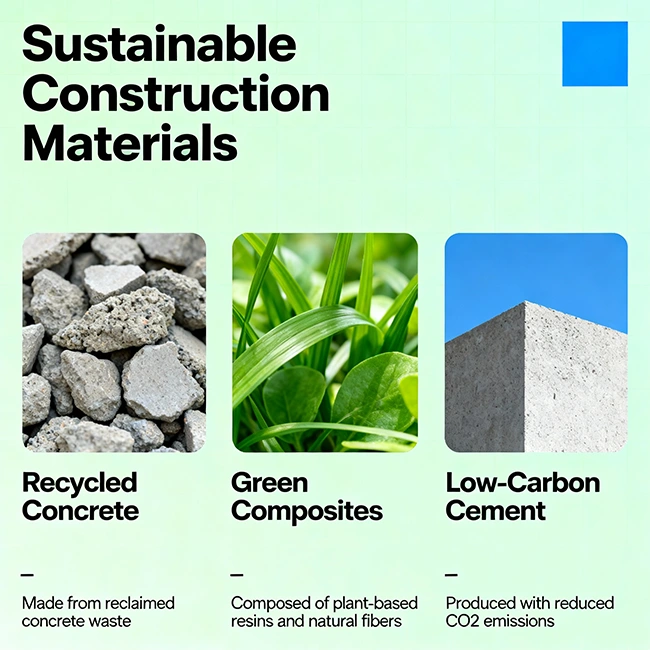

Low-carbon cement represents perhaps the most significant breakthrough in sustainable industrial construction materials. Traditional Portland cement manufacturing produces substantial CO2 emissions through both the combustion process and limestone calcination. Revolutionary alternatives are transforming this landscape through innovative chemical compositions and production methods.

Supplementary cementitious materials (SCMs) have gained prominence as effective cement replacements. Fly ash, ground granulated blast furnace slag (GGBFS), and metakaolin can replace 15-40% of traditional cement while maintaining or improving structural properties. These materials utilize industrial waste products, creating circular economy benefits while reducing embodied carbon by up to 70%.

Limestone-calcined clay cement (LC³) technology represents another groundbreaking advancement. This approach combines limestone and calcined clay to create high-performance cement with significantly reduced carbon emissions. Research demonstrates that LC³ can achieve comparable strength properties to traditional cement while reducing CO2 emissions by up to 40%.

Emerging carbon capture and utilization technologies are revolutionizing cement production further. Companies are developing processes that incorporate captured CO2 directly into concrete mixtures, creating carbon-negative materials that actually sequester atmospheric carbon during the curing process.

Advanced Recycled Concrete Applications

Recycled concrete has evolved from simple aggregate replacement to sophisticated engineered materials that surpass traditional concrete performance in many applications. Modern recycled concrete utilizes advanced processing techniques to create high-quality aggregates from demolished structures, reducing landfill waste while conserving natural resources.

Contemporary recycled concrete applications incorporate multiple waste streams. Crushed concrete provides coarse aggregates, while recycled concrete powder can partially replace cement in new mixtures. This approach creates closed-loop systems where demolished industrial structures provide raw materials for new construction projects.

Quality enhancement technologies have addressed traditional concerns about recycled concrete performance. Advanced washing and separation processes remove contaminants, while carbonation treatments improve the properties of recycled aggregates. These processes ensure that recycled concrete meets or exceeds performance standards for demanding industrial applications.

Innovative binding technologies are expanding recycled concrete applications. Alkali-activated systems using industrial waste materials create high-strength concrete with superior durability characteristics. These systems demonstrate excellent resistance to chemical attack, making them particularly suitable for industrial facilities exposed to harsh environmental conditions.

Green Composite Material Innovations

Green composites represent a paradigm shift from traditional petroleum-based materials toward bio-based alternatives that maintain structural integrity while reducing environmental impact. These materials combine natural fibers with bio-based or recycled matrix materials to create high-performance construction components.

Bio-fiber reinforcement technologies utilize agricultural waste products such as hemp, flax, and bamboo fibers to create structural composites. These materials demonstrate excellent tensile strength and flexibility while providing superior thermal and acoustic insulation properties. Industrial applications include non-load-bearing walls, insulation systems, and architectural elements.

Mycelium-based composites represent cutting-edge bio-material technology. Fungal root structures grow around agricultural waste to create lightweight, strong, and completely biodegradable building materials. These materials can be molded into complex shapes and provide excellent fire resistance and insulation properties.

Recycled plastic composites transform waste plastic into durable construction materials. Advanced processing techniques create lumber-like products from mixed plastic waste, providing weather-resistant alternatives to traditional wood products. These materials demonstrate superior durability and require minimal maintenance throughout their service life.

Circular Economy Integration

The adoption of sustainable materials in industrial construction necessitates comprehensive circular economy approaches that maximize resource efficiency throughout the building lifecycle. This integration involves sophisticated material tracking systems, design-for-disassembly principles, and end-of-life material recovery protocols.

Digital material passports are emerging as essential tools for tracking sustainable materials throughout their lifecycle. These systems document material composition, performance characteristics, and environmental impact data, enabling informed decision-making for future reuse and recycling applications.

Modular construction approaches facilitate circular economy principles by creating standardized components that can be easily disassembled and reused. Industrial facilities designed with modular systems can be reconfigured, expanded, or relocated with minimal material waste and maximum value retention.

Performance Optimization and Quality Assurance

Sustainable materials must meet rigorous performance standards for industrial construction applications. Advanced testing protocols ensure that eco-friendly alternatives provide comparable or superior performance to traditional materials while maintaining safety and durability requirements.

Accelerated aging tests evaluate long-term performance characteristics of sustainable materials under various environmental conditions. These protocols simulate decades of weathering, chemical exposure, and mechanical stress to validate material performance predictions.

Smart monitoring systems integrated into sustainable construction materials provide real-time performance data throughout the building lifecycle. Embedded sensors track structural integrity, moisture levels, and environmental conditions, enabling predictive maintenance and optimized performance management.

Economic and Implementation Considerations

The economic case for sustainable materials in industrial construction extends beyond initial material costs to encompass lifecycle value propositions. While some sustainable materials may have higher upfront costs, they frequently provide superior long-term value through reduced maintenance, improved energy efficiency, and enhanced durability.

Supply chain development remains crucial for widespread sustainable material adoption. Regional material sourcing reduces transportation emissions while supporting local economies. Investment in local processing facilities creates resilient supply networks that reduce dependency on distant suppliers.

Training and certification programs ensure proper implementation of sustainable materials. Construction professionals require specialized knowledge to optimize the performance of eco-friendly alternatives, making education and skill development essential components of successful sustainable construction projects.

Future Trajectories and Innovation Horizons

The future of sustainable materials in industrial construction promises continued innovation across multiple fronts. Nanotechnology applications are creating materials with enhanced properties, while biotechnology advances enable completely new categories of bio-based construction materials.

Artificial intelligence and machine learning are optimizing sustainable material formulations for specific applications. These technologies can predict material performance, optimize mixing ratios, and identify optimal combinations of sustainable materials for particular environmental conditions and performance requirements.

The integration of renewable energy systems with sustainable materials creates synergistic benefits. Solar-integrated building materials, energy-storing concrete, and thermally responsive materials represent the next generation of multifunctional sustainable construction components.

Regulatory Framework and Standards Evolution

Building codes and standards are evolving rapidly to accommodate and encourage sustainable material adoption. Performance-based standards focus on environmental impact metrics alongside traditional structural and safety requirements, creating frameworks that reward sustainable innovation.

Certification systems provide third-party verification of sustainable material performance and environmental benefits. These systems enable specifiers to confidently select sustainable alternatives while ensuring compliance with project requirements and regulatory standards.

The transformation toward sustainable materials in industrial construction represents a fundamental shift in how we conceive, design, and construct the built environment. Through innovative material technologies, circular economy principles, and comprehensive performance optimization, sustainable materials are not merely alternatives to traditional construction materials—they represent the future of industrial construction itself.

As the industry continues to embrace these technologies, the convergence of environmental responsibility and superior performance will drive unprecedented innovation, creating industrial facilities that serve as models of sustainability while meeting the demanding requirements of modern industrial operations. The journey toward truly sustainable industrial construction has begun, and sustainable materials are leading the way toward a more environmentally responsible and economically viable future.