Hanhwa Engineering and Construction (Hanhwa E&C) is rethinking how it approaches construction projects by deploying the latest innovative smart construction technology.

“We are currently utilizing robot dogs with 3-D scanners as well as augmented reality (AR) technology for the construction project in Seoul Station,” said Hanwha E&C CEO Kim Seung-mo.

The multi-complex construction project is a large scale innovation intended to transform unused railroad sites in the northern part of Seoul Station into a dynamic area with countless facilities such as commercial and cultural complexes. This scheme is worth approximately 2 trillion won ($1.4 billion) and is expected to become the COEX of northern Seoul.

One of the smart construction technology systems being used at the site is a robot dog that walks on four legs. This smart device assists workers by accumulating and processing required data via a 3-D scanner. The robot is also able to scan places that might be too dangerous for human workers.

Hanhwa E&C demonstrated its smart technology at the construction site on Sept. 27.

The company equipped Boston Dynamics’ robot Spot with Trimble’s X7, a 3-D laser scanner model, allowing the robot to calculate elevation levels and the volume of earth in the terrain. Hanhwa E&C plans to utilize the figures when displacing nearby buildings during construction.

“The inventive technique removes the burden of workers who have to physically move around 3-D scanners and tripods in harsh weather conditions,” said a Hanhwa E&C official. “There existed many practice tests using robot dogs, but this is our first practical deployment on an actual construction site, which adds to the project’s significance.”

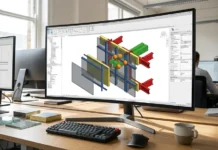

Hanhwa E&C additionally displayed its AR technology based on a global navigation satellite system in the demonstration. Workers identified the site by observing the building information modeling (BIM), a virtual imitation of the actual area. With a simple tap on their cellphones, workers could assess the terrain boundaries, view the blueprints and establish construction plans.

0

BIM technology combines 3-D models and construction information to navigate through the process of construction. Users can check processing procedures as well as acute information on building components right away from the designing stage, greatly assisting the comprehension of workers on the properties of the building.

The construction project takes place right next to active railroads. As such, ensuring that train operations are not interrupted, particularly during underground manufacturing, is crucial. Hanhwa E&C is aware of such preliminary inspections and plans to fully utilize AR and BIM technology to ensure the safety of the construction.

“Our dedication to smart construction technology will prevail throughout future projects, maximizing the productivity and competitiveness of our technological assets,” said Yoon Yong-sang, head of Hanwha E&C’s construction division.