The construction sector stands at a pivotal crossroads, driven by the urgent need for sustainable practices that reduce carbon emissions and minimise environmental impact. Among the frontiers of innovation is the integration of hydrogen-powered drilling technology, a promising development that could revolutionise geotechnical construction. This advancement offers a cleaner, more efficient alternative to traditional fossil fuel-based drilling processes, aligning with global sustainability targets and evolving regulatory standards.

Hydrogen-powered drilling not only promises to significantly cut greenhouse gas emissions but also opens new avenues for operational efficiency, safety, and technological integration. As the construction industry confronts increasing pressure to adopt greener solutions, understanding how this emerging technology can reshape workflows, environmental impact, and industry standards becomes essential.

The Emerging Role of Hydrogen in Geotechnical Construction

Hydrogen has long been recognized as a versatile energy carrier with applications across transportation, industry, and power generation. However, its role in the construction sector, particularly in geotechnical engineering, is only beginning to unfold. Traditionally, drilling operations, be it for foundation piles, geothermal energy, or subsurface investigation, depend heavily on diesel or other fossil fuels for power. These methods, while effective, contribute significantly to greenhouse gas emissions, noise pollution, and operational hazards.

This shift aligns with decarbonisation agendas worldwide, where reducing carbon footprint and complying with stricter environmental standards are critical drivers. Hydrogen-powered drilling machinery promises to provide enhanced operational capacities while significantly lowering environmental impacts. This makes it an attractive option for future-forward construction projects.

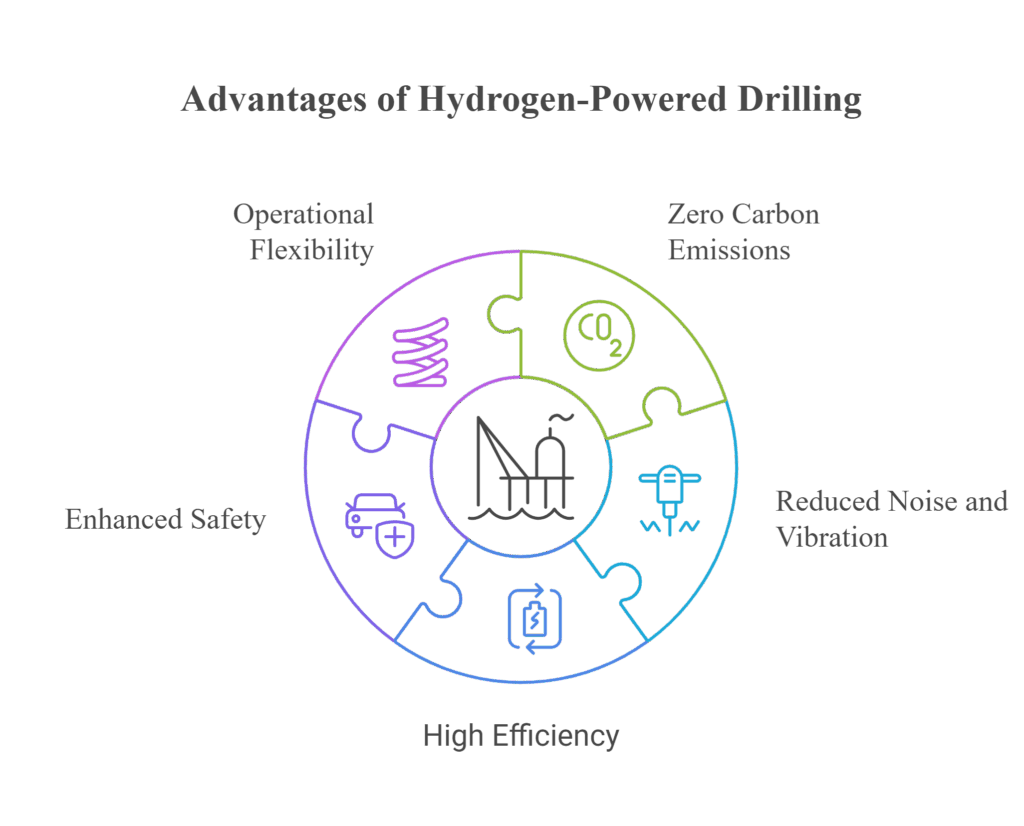

Key Advantages of Hydrogen-Powered Drilling

Hydrogen-powered drilling machines use fuel cell technology or hydrogen combustion engines capable of delivering comparable, if not superior, performance relative to conventional equipment. The advantages of hydrogen-powered drilling include:

- Zero Carbon Emissions

Hydrogen-powered drilling significantly advances environmental sustainability by eliminating carbon emissions. Unlike traditional diesel or fossil fuel-driven machinery, hydrogen fuel cells produce only water vapour as a byproduct during operation. This fundamental attribute makes hydrogen-powered drilling machines incredibly appealing in an era where reducing global greenhouse gases is paramount.

By adopting hydrogen as a power source, construction firms can drastically cut their carbon footprint, particularly in urban or environmentally sensitive areas where strict regulations restrict emissions. Furthermore, as hydrogen can be produced from renewable energy sources such as wind and solar, it enables a closed-loop green energy cycle. This closed-loop green energy cycle means that the entire drilling operation can be emissions-free if powered sustainably.

In addition to compliance benefits, zero emissions contribute to improved air quality around construction sites. This reduces health hazards for workers and nearby communities.

- Reduced Noise and Vibration

One of the notable advantages of hydrogen-powered drilling equipment is the substantial reduction in noise pollution. Traditional diesel engines, especially those used in drilling rigs, generate loud, high-frequency noise that disturb urban populations, wildlife habitats, and sensitive ecosystems. Hydrogen fuel cells operate more quietly and smoothly, producing minimal vibration and acoustical disturbance during operation.

This quieter operation is particularly advantageous for construction projects in urban environments, alongside hospitals, schools, and residential neighborhoods. Reduced noise levels not only improve site conditions but also enhance worker safety and comfort, leading to better productivity.

Furthermore, the lowered vibration produced by hydrogen engines minimises structural vibrations transmitted to surrounding ground and structures. This is essential when working in densely built areas or near historic landmarks where vibrations can cause damage or disturbances. It also reduces wear and tear on equipment and surrounding infrastructure, potentially extending the lifespan of both the machinery and adjacent structures.

With increasing awareness around noise pollution and vibration impacts, hydrogen-powered drilling equipment offers a sustainable alternative that reconciles environmental and social responsibility in the construction industry.

- High Efficiency

Hydrogen-powered drilling machinery demonstrates remarkable efficiency gains over conventional fossil-fuel systems. Fuel cells, such as Proton Exchange Membrane (PEM) systems, convert hydrogen into electricity. This is done through electrochemical reactions that reach higher conversion efficiencies compared to internal combustion engines. This efficiency translates into less fuel consumption for the same power output, reducing operational costs.

Additionally, hydrogen engines designed for industrial applications have undergone continuous improvements. This allows for higher thermal efficiency and better power-to-weight ratios. They are capable of delivering power more consistently and with fewer fluctuations, which is critical for maintaining precision and stability during sensitive geotechnical operations.

One of the major benefits of higher operational efficiency is the cost savings over the lifecycle of the machinery. Reduced fuel used directly impacts the operational expenditure, especially in remote or large-scale projects where fuel logistics and transportation costs are significant considerations.

Moreover, technological advancements like hybrid systems, combining fuel cell and battery storage further optimises energy use, improves start-up times, and enables dynamic response to varying workload demands.

- Enhanced Safety

The safety profile of hydrogen-powered drills has seen substantial enhancements through modern engineering and strict regulatory standards. Initially, safety concerns around hydrogen, such as flammability and the risk of explosions persisted, but advances in technology and infrastructure have mitigated these issues significantly.

Hydrogen fuel is stored at high pressures in reinforced composite tanks that are designed with multiple containment layers and safety valves to prevent leaks or ruptures. The sensors for leak detection and fire suppression systems are incorporated into hydrogen machinery, ensuring rapid response if any anomalies are detected.

Hydrogen-powered drills produce fewer emissions and less noise, reducing risks associated with inhaling harmful fumes or respiratory hazards. The safety enhancements ultimately foster a safer work environment, reduce risk premiums on construction insurance, and promote broader acceptance of hydrogen technology across the industry.

- Operational Flexibility

Hydrogen-powered drilling machinery offers unparalleled operational flexibility. This is a key factor in advancing modern geotechnical construction methods. Fuel cell systems and hydrogen combustion engines can start quickly, often within minutes compared to conventional diesel engines that can take much longer to reach operational speeds.

This rapid start-up capability allows drill operators to respond swiftly to project demands, schedule changes, or emergency situations. This thereby minimises downtime and increases overall productivity. Hydrogen systems are also highly scalable, with modular designs that can be tailored to project size and utility requirements.

Technological Foundations of Hydrogen-Powered Drilling

At the core of hydrogen-powered drilling systems are fuel cell technology and hydrogen combustion engines. Fuel cells, particularly the Proton Exchange Membrane (PEM) fuel cells are well-suited for construction applications. This is due to their rapid startup capabilities, high power density, and modular design. These systems generate electricity by electrochemical reactions, with the only byproduct being pure water.

Hydrogen combustion engines, meanwhile, operate similarly to traditional internal combustion engines but burn hydrogen instead of fossil fuels. These engines are designed to withstand high pressures and temperatures, and recent advancements have improved their reliability, power output, and emissions profile.

Hydrogen storage on-site is facilitated through pressurised tanks or cryogenic systems. Innovations in storage materials, such as high-strength composites, reduce weight and improve safety margins. The infrastructure for refueling and maintaining these systems is evolving rapidly, supported by industry standards and safety protocols.

Furthermore, integration with automation and digital monitoring systems enhances operational control, predictive maintenance, and safety management.

Industry and Market Implications

The integration of hydrogen-powered drilling into the construction sector signifies a paradigm shift toward cleaner, safer, and more efficient practices. Industry leaders see this as part of a broader movement toward green construction, with hydrogen playing a central role in achieving decarbonisation goals.

Market forecasts suggest that the adoption of hydrogen-powered construction machinery will accelerate over the next decade. This is driven by technological advancements, supportive policies, and rising client demand for sustainable projects. Companies investing early in hydrogen infrastructure and equipment will likely gain significant competitive advantages.

Challenges remain, particularly concerning the high initial capital expenditure for hydrogen systems, infrastructure, and safety compliance. However, economies of scale, regulatory support, and ongoing innovation are expected to reduce costs, making the technology more accessible globally.

The shift also prompts a reevaluation of supply chains, with an increased emphasis on hydrogen production, storage, and refueling infrastructure development. Collaboration among technology providers, construction firms, and policymakers will be essential to overcome barriers and realize the full potential of hydrogen in geotechnical construction.

Future Outlook and Strategic Pathways

As global awareness of climate change and environmental concerns rises, the construction industry will increasingly turn toward hydrogen-powered solutions. The outlook suggests a gradual but steady replacement of fossil-fuel-based machinery in geotechnical works, particularly for large infrastructure projects.

Innovation in hydrogen storage, portable fuel cells, and hybrid systems will further enhance operational flexibility. The integration of digital technologies for remote monitoring, predictive maintenance, and safety management will make hydrogen more viable and reliable in demanding environments.

Policymakers and industry stakeholders play a crucial role in this evolution, implementing supportive policies, standardization, and investment incentives. The development of regional hydrogen ecosystems, covering production, storage, and refueling, will be instrumental in scaling adoption.

Conclusion: A New Frontier in Sustainable Construction

Hydrogen-powered drilling stands poised to redefine the future of geotechnical construction, delivering cleaner, safer, and more efficient operations. By harnessing hydrogen fuel cell and combustion technologies, the construction industry can significantly diminish its environmental footprint while maintaining high standards of safety and performance.

The transition will require ongoing innovation, collaborative efforts, and supportive policy frameworks. As the sector moves toward integrating hydrogen solutions, it not only addresses environmental challenges but also opens new opportunities for technological leadership, economic growth, and resilience in the face of climate change. Hydrogen-powered drilling represents more than a technological evolution, it embodies the future of sustainable, responsible construction.