Key Takeaways:

- The implementation of prefabrication techniques on site construction risk reduction significantly lowers worker exposure to dangerous conditions such as height-related tasks and unpredictable weather.

- Factory-controlled environments allow for superior quality assurance and precision engineering, resulting in structures that are more durable and structurally sound than those built through traditional on-site methods.

- By condensing project timelines and reducing material waste, prefabrication provides a dual benefit of financial efficiency and environmental sustainability, making it the preferred choice for modern urban development.

Prefabrication Techniques Reducing On Site Construction Risk

The traditional construction site is an inherently volatile environment, characterized by a multitude of moving parts, unpredictable weather conditions, and high-risk activities performed at height. For decades, the industry has sought ways to improve safety and efficiency, but it is only with the recent rise of sophisticated off site manufacturing that a truly transformative solution has emerged. By shifting a significant portion of the building process into a controlled factory setting, the prefabrication techniques on site construction risk mitigation requires are finally being realized at scale. This evolution is not just about building faster; it is about creating a safer, more predictable, and higher-quality path to project completion.

The Shift from Chaos to Control

At the heart of why prefabrication techniques on site construction risk reduction is so effective is the concept of environmental control. In a traditional setting, workers are exposed to the elements, uneven terrain, and the logistical nightmare of coordinating dozens of subcontractors in a confined space. In contrast, a prefabrication facility offers a stable, well-lit, and ergonomically optimized workspace. Here, components are built using precision machinery and standardized processes. This stability eliminates many of the variables that lead to accidents, such as slips, trips, and falls, which remain the leading cause of injury in the construction sector.

Reducing Exposure to High-Risk Activities

One of the most significant safety benefits of prefabricated construction is the drastic reduction in work performed at height. When wall panels, floor cassettes, or entire modular units are assembled on a factory floor, workers can operate at ground level or on stable platforms. By the time these components reach the site, they are ready for quick installation, which minimizes the time laborers spend on scaffolding or ladders. This reduction in exposure is a cornerstone of the prefabrication techniques on site construction risk management strategies that modern developers are increasingly adopting to protect their workforce.

Logistical Safety and Traffic Management

Beyond the physical acts of building, traditional sites are plagued by heavy vehicle traffic, from concrete mixers to delivery trucks. Every vehicle movement represents a potential hazard. Off site manufacturing streamlines this by consolidating deliveries. Instead of hundreds of small shipments, a modular project might require only a few dozen carefully timed deliveries of completed units. This not only reduces the risk of on-site collisions but also minimizes the disruption to the surrounding community, which is a critical factor in dense urban environments.

Enhancing Quality Control and Building Integrity

Safety is often seen as a physical concern, but it is also a structural one. A building that is poorly constructed poses a long-term risk to its occupants. Prefabrication techniques on site construction risk reduction extend into the realm of quality assurance. In a factory, inspections can be carried out at every stage of the assembly line. Because the work is sheltered from rain and wind, materials like timber and insulation are never exposed to moisture, preventing issues like mold growth or structural warping before the building is even enclosed.

Precision Engineering and Modular Building

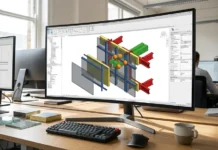

The level of precision achievable in a factory setting far exceeds what can be done in the field. Using Building Information Modeling (BIM) data, components are cut and assembled with millimeter accuracy. This ensures that when modular units arrive on site, they fit together perfectly. This “plug-and-play” nature of modular building reduces the need for “on-the-fly” adjustments, which are often where errors and shortcuts occur. By ensuring that every joint, seal, and fastener is installed according to exact specifications, prefabrication techniques on site construction risk associated with structural failure are substantially lowered.

Addressing the Labor Shortage and Skill Gap

The construction industry is currently facing a global shortage of skilled labor. This shortage often forces companies to rely on less experienced workers, which can inadvertently increase the risk of accidents and poor workmanship. Prefabrication offers a solution by shifting the labor model from craft-based on-site work to assembly-based factory work. This allows for a more specialized workforce that can be trained more effectively in a specific set of tasks. The repetition inherent in off site manufacturing leads to mastery, which naturally results in fewer mistakes and a safer working environment.

Construction Efficiency and Project Timelines

Speed is often cited as the primary driver for prefabrication, but its relationship with risk is profound. The longer a project drags on, the longer the site is exposed to weather-related damage, theft, and safety incidents. By overlapping the site preparation phase with the factory production phase, developers can cut project timelines by 30% to 50%. This condensed schedule significantly narrows the “window of risk,” allowing the project to reach the “dry-in” stage much faster. This efficiency is a direct result of the prefabrication techniques on site construction risk mitigation that have become essential in today’s fast-paced market.

Environmental and Sustainability Benefits

While safety and efficiency are paramount, the environmental impact of construction is a risk that modern society can no longer ignore. Traditional construction is notoriously wasteful, with significant amounts of material ending up in landfills due to over-ordering or damage on site. Prefabrication facilities use advanced software to optimize material usage, drastically reducing waste. Furthermore, the ability to recycle off-cuts within the factory environment further enhances the sustainability profile of the project.

Reducing the Carbon Footprint of Building Sites

By reducing the number of vehicle trips to the site and the amount of heavy machinery running on-site for extended periods, prefabrication helps lower the overall carbon footprint of a project. Additionally, the improved thermal performance of factory-built components ensures that the building operates more efficiently throughout its lifecycle. In this context, prefabrication techniques on site construction risk management also encompass the long-term risk of environmental non-compliance and high energy costs for the end-user.

The Future of Prefabrication in Global Markets

As we look to the future, the adoption of prefabrication is set to accelerate. Advances in robotics and 3D printing are further enhancing the capabilities of off site manufacturing. We are seeing the emergence of “smart factories” where AI monitors the production line for any deviations from safety or quality standards. The integration of these technologies ensures that the prefabrication techniques on site construction risk reduction will continue to evolve, offering even greater levels of protection and performance.

Overcoming Perceptions and Scaling Up

Despite the clear advantages, the industry must still overcome old perceptions that prefabricated buildings are “temporary” or of lower quality. Modern modular high-rises in cities like London, New York, and Singapore are proving that this is far from the truth. These structures are often more robust than their traditionally built counterparts. As more developers witness the tangible benefits of reduced insurance premiums, fewer site accidents, and faster returns on investment, the shift toward prefabrication will become the new standard for construction excellence.

The Crux of Construction Innovation

In conclusion, the transition toward off-site methods represents the most significant leap in building technology in a generation. The core of this movement the prefabrication techniques on site construction risk mitigation is the key to unlocking a safer and more efficient future for the industry. By prioritizing precision, control, and worker safety, we are not just building better structures; we are building a more sustainable and resilient world.