Nature’s engineering solutions, refined through millions of years of evolution, offer profound lessons for human innovation. Biological systems demonstrate remarkable capabilities that manufactured materials struggle to replicate: self-repair following damage, adaptation to environmental conditions, efficient use of resources, and eventual decomposition without persistent environmental harm. The emerging field of bio-inspired concrete applies these natural principles to one of humanity’s most ubiquitous construction materials, transforming inert cement and aggregate into intelligent, responsive systems that address critical sustainability and performance challenges facing the built environment.

Self-Healing Concrete: Mimicking Biological Repair Mechanisms

The concept of self-healing concrete represents perhaps the most transformative application of biomimicry in construction materials. Traditional concrete’s brittle nature makes it vulnerable to cracking from shrinkage, thermal stresses, mechanical loading, and countless other factors. These cracks, while often small initially, provide pathways for water and chemicals to penetrate concrete matrices, accelerating corrosion of reinforcement and degradation of the material itself. The resulting maintenance burden represents massive economic and environmental costs, with concrete infrastructure repair and replacement consuming substantial resources globally.

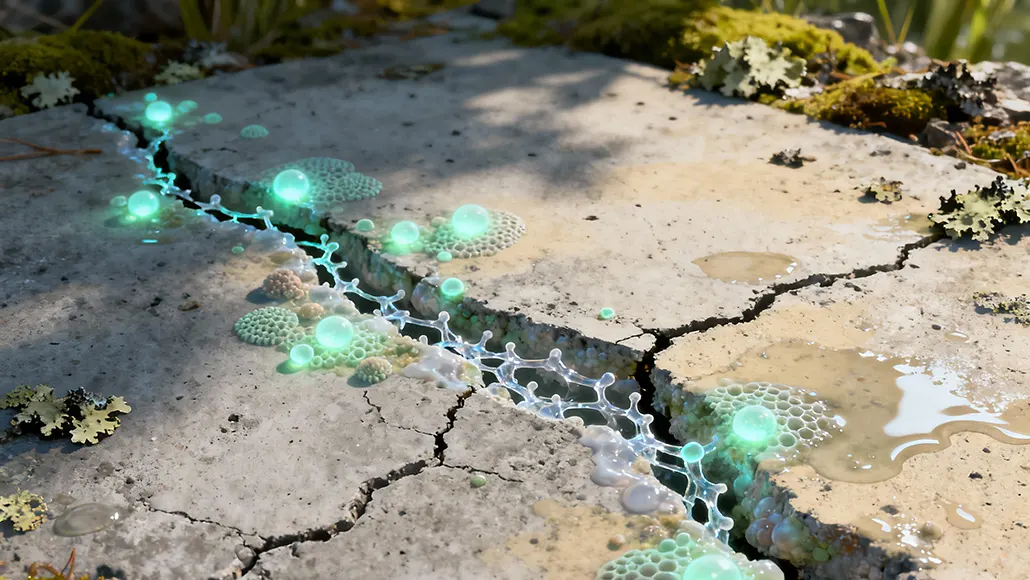

Bio-inspired self-healing concrete employs bacterial systems that mimic biological healing responses. The most commonly deployed approach incorporates spore-forming bacteria from the Bacillus genus along with calcium-based nutrients into concrete mixes. These bacterial spores remain dormant within the concrete matrix, protected from the harsh alkaline environment and capable of surviving decades without deterioration. When cracks form and moisture penetrates the concrete, the dormant bacteria activate and begin consuming the embedded nutrients. This metabolic process produces limestone in the form of calcium carbonate as a byproduct, which precipitates within cracks and gradually seals them.

The healing mechanism operates through a biochemical process called microbially induced calcite precipitation. Bacteria possessing urease enzymes break down urea added as a nutrient source, producing ammonia and carbon dioxide. These compounds increase local pH and provide carbonate ions that react with calcium present in the cement matrix, forming calcium carbonate crystals that grow and fill crack volumes. Research demonstrates that properly formulated bacterial concrete can seal cracks up to 0.5 millimeters wide, dimensions sufficient to address the majority of problematic cracking in structural applications.

Alternative approaches to self-healing concrete employ different mechanisms inspired by biological systems. Algae-based healing agents leverage photosynthetic microorganisms that promote calcium carbonate formation through their metabolic activities. These systems offer potential carbon sequestration benefits alongside crack healing capabilities, as the algae consume carbon dioxide during growth. Polymer-based healing systems incorporate microcapsules containing repair compounds that rupture when cracks propagate through them, releasing adhesive materials that bond crack faces together. This approach mimics blood clotting in biological systems, with the repair compounds serving similar functions to platelets and fibrin networks in wound healing.

The performance benefits of self-healing concrete extend across multiple dimensions beyond simple crack repair. Water permeability reductions approaching 80 percent have been documented in healed samples, substantially improving durability by limiting ingress of aggressive substances. Compressive and flexural strength recovery reaches significant levels when healing proceeds effectively, in some cases restoring substantial portions of original structural capacity. The most transformative impact emerges in extended service life projections, with self-healing capabilities potentially doubling or tripling the functional lifespan of concrete structures compared to conventional materials.

Algae-Based Concrete Systems and Carbon Sequestration

Algae integration into concrete systems represents a frontier where sustainability objectives and performance enhancement converge. Beyond their role in crack healing, algae contribute to concrete technology through multiple mechanisms. Cyanobacteria and microalgae species incorporated into concrete formulations can bind particles together through biopolymer production, creating cohesive matrices with reduced cement requirements. This biomineralization process, where microorganisms facilitate mineral precipitation and consolidation, offers pathways to substantially reduce portland cement consumption, addressing one of construction’s largest carbon emission sources.

The emerging field of algae-based biocement envisions concrete production methods that replace chemical cement manufacturing with biological processes. Companies including Biomason, Prometheus Materials, and Biozeroc are developing technologies where bacteria create binding materials through natural metabolic processes rather than energy-intensive calcination of limestone. These biogenic cements demonstrate comparable or superior performance to conventional materials while dramatically reducing embodied carbon. Early-stage products show promise for applications including masonry units, architectural panels, and eventually structural components as technology matures and production scales.

Living concrete incorporating photosynthetically-active organisms presents even more radical possibilities. Research prototypes embed algae throughout concrete matrices where they remain viable and continue performing photosynthesis after placement. These systems actively absorb carbon dioxide from the atmosphere throughout their service lives, transforming concrete from a significant carbon emission source into a carbon-sequestering material. While technical challenges including ensuring adequate light penetration, maintaining organism viability, and preventing surface biofouling require resolution before widespread deployment, the concept demonstrates the transformative potential of bio-inspired approaches.

The scalability and economic viability of algae-based concrete technologies are advancing steadily. Cultivation systems for producing sufficient algae biomass at costs competitive with conventional cement remain challenging, but process improvements and increasing scale drive costs downward. The global biocement market, valued at approximately 30 million dollars in 2024, projects growth exceeding 10 percent annually as technology matures and sustainability imperatives strengthen. Government incentives for low-carbon construction materials and potential carbon credit revenues improve economic analyses, potentially accelerating adoption timelines.

Photocatalytic Concrete for Air Quality Improvement

The integration of photocatalytic materials into concrete surfaces enables structures to actively improve urban air quality, transforming passive building envelopes into pollution-reduction systems. This technology incorporates titanium dioxide into concrete mixes or surface treatments, creating materials that catalyze decomposition of airborne pollutants when exposed to light. The titanium dioxide functions analogously to chlorophyll in plants, harvesting light energy to drive chemical reactions that break down harmful substances.

The photocatalytic mechanism operates through generation of highly reactive hydroxyl radicals and superoxide ions when titanium dioxide absorbs ultraviolet light. These reactive species attack organic compounds and nitrogen oxides in contact with the concrete surface, breaking them down into harmless substances including carbon dioxide, water, and nitrates that rain washes away. Field studies demonstrate that photocatalytic concrete surfaces can reduce nitrogen oxide concentrations by 15 to 80 percent depending on environmental conditions, pollution levels, and surface geometry.

The technology proves particularly effective in urban canyon environments where limited air circulation concentrates vehicle emissions and industrial pollutants. Narrow streets with tall buildings on both sides trap pollution at ground level where pedestrians experience maximum exposure. Photocatalytic concrete pavements and building facades in these locations provide substantial air quality benefits measurable in health outcome improvements. Projects in multiple countries have deployed this technology specifically targeting high-pollution urban areas, with monitoring confirming significant reductions in nitrogen dioxide, volatile organic compounds, and particulate matter concentrations.

Secondary benefits beyond air purification enhance the value proposition for photocatalytic concrete. The same catalytic processes that decompose airborne pollutants also break down organic materials deposited on concrete surfaces, providing self-cleaning functionality that maintains aesthetic appearance while reducing maintenance requirements. Buildings treated with photocatalytic coatings resist discoloration from atmospheric pollution, biological growth, and organic contamination, preserving architectural finishes and reducing pressure washing or chemical cleaning needs.

Recent advances focus on enhancing photocatalytic efficiency under visible light rather than requiring ultraviolet radiation. Standard titanium dioxide responds primarily to UV wavelengths, limiting effectiveness in northern latitudes with less intense sunlight or interior applications. Doping titanium dioxide with nitrogen, carbon, or transition metals shifts its spectral response toward visible wavelengths, maintaining catalytic activity under indoor lighting or cloudy conditions. These modified photocatalysts expand potential applications while improving performance in less ideal lighting conditions.

Integration Challenges and Implementation Strategies

The transition of bio-inspired concrete from laboratory research to widespread field deployment encounters multiple technical and practical challenges. Ensuring bacterial viability throughout concrete mixing, placement, and curing represents a fundamental requirement for self-healing systems. The high pH environment of fresh concrete, typically exceeding pH 12, proves lethal to most microorganisms. Encapsulation techniques protecting bacteria within porous aggregates, hydrogel carriers, or polymer shells address this challenge while maintaining their accessibility to moisture and nutrients when cracks form. Optimization of encapsulation materials and methods remains an active research area balancing bacterial protection against release efficiency and cost.

Long-term bacteria survival within concrete matrices determines whether self-healing capabilities remain available throughout structure service lives. Studies confirm that properly selected bacterial strains can remain viable in spore form for years or decades, but environmental factors including temperature extremes, freeze-thaw cycling, and chemical exposure influence survival rates. Formulation adjustments tailoring nutrient availability, protection mechanisms, and bacterial species selection to specific exposure conditions optimize longevity while managing costs.

Quality control and performance verification present unique challenges for bio-inspired concrete systems. Traditional concrete testing focuses on mechanical properties measurable through standardized procedures producing quantitative results. Confirming that adequate bacterial populations remain viable within concrete requires specialized techniques beyond typical ready-mix quality assurance capabilities. Development of practical field testing methods verifying self-healing functionality enables contractors and inspectors to confirm that delivered materials meet specifications without requiring sophisticated laboratory analysis.

Cost considerations significantly influence adoption rates for bio-inspired concrete technologies. Bacterial concrete can cost 20 to 40 percent more than conventional concrete due to specialized additives, bacteria cultivation, and encapsulation materials. These initial cost premiums must be justified through life-cycle value including reduced maintenance, extended service life, and enhanced performance. Economic analyses increasingly support bio-inspired approaches when total ownership costs receive consideration rather than focusing exclusively on initial construction expenses.

Regulatory frameworks and building codes, developed around conventional concrete properties and performance verification methods, lag emerging bio-inspired technologies. Establishing appropriate specifications, testing protocols, and acceptance criteria for self-healing or photocatalytic concrete requires collaboration among researchers, practitioners, materials suppliers, and code officials. Progressive jurisdictions develop pilot programs allowing bio-inspired concrete deployment under enhanced monitoring, generating performance data supporting broader code acceptance.

Market Evolution and Future Trajectories

The global market for bio-inspired concrete technologies demonstrates accelerating growth trajectories reflecting both technological maturation and mounting sustainability imperatives. The self-healing concrete market, valued at 34 to 111 million dollars in 2025 depending on scope definitions, projects compound annual growth rates approaching 29 to 37 percent through 2032. These remarkable expansion rates reflect early-stage market development where percentage growth rates appear dramatic, but also signal genuine momentum as materials transition from research curiosities to viable construction products.

Adoption patterns vary across geographic regions and application types. European markets lead deployment, driven by stringent sustainability requirements, substantial infrastructure maintenance backlogs, and progressive building codes accommodating innovative materials. Asian markets, particularly in rapidly urbanizing areas confronting severe air pollution challenges, show strong interest in photocatalytic concrete for urban air quality management. North American adoption progresses more gradually, though mounting infrastructure deterioration and increasing sustainability focus suggest acceleration.

Application niches where bio-inspired concrete delivers maximum value relative to conventional alternatives drive current adoption. Infrastructure subject to harsh exposure conditions and difficult access for maintenance, including bridge decks, marine structures, and tunnel linings, represents prime territory where extended service life justifies material cost premiums. Prestigious architectural projects incorporating sustainability as core design objectives accept bio-inspired concrete as differentiation enabling claims of environmental leadership. Demonstration projects sponsored by research institutions and material suppliers continue generating performance data and practical experience supporting broader deployment.

Technology development roadmaps emphasize performance enhancement, cost reduction, and expanded functionality. Genetic engineering approaches modifying bacterial strains improve calcite production rates, stress tolerance, and environmental adaptability. Hybrid systems combining multiple healing mechanisms provide redundancy and address limitations of individual approaches. Integration with other smart concrete technologies including embedded sensors creates comprehensive material systems offering both active monitoring and autonomous repair capabilities.

The convergence of sustainability imperatives, technological capability, and economic viability positions bio-inspired concrete as increasingly central to construction’s evolution toward environmental responsibility. These materials exemplify how drawing inspiration from nature’s solutions, refined through millions of years of evolutionary optimization, enables human innovation transcending the limitations of purely engineering-based approaches. As bio-inspired concrete matures from promising research direction to established construction practice, it demonstrates pathways toward built environments that work in harmony with natural systems rather than in opposition to them, supporting both human needs and planetary health across generations.