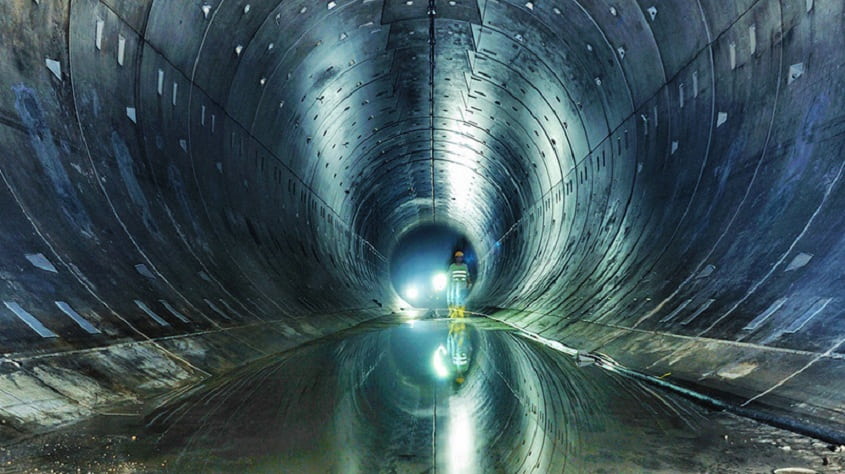

A pivotal infrastructure project both for the environment and the country’s sanitation network. Leveraging large-scale tunnel-construction expertise to meet urban sanitation needs.

VINCI Construction Grands Projets, in joint venture with its British partner Costain, has just delivered Scotland’s longest wastewater tunnel. At 4.7 metres in diameter and 5 kilometres in length, this major structure, valued at £100 million (€115 million), is part of a programme by Scottish Water, the national water-management authority, designed to enhance water quality, preserve the environment, and prevent flooding in and around Glasgow. On July 30, 2018, Roseanna Cunningham, Scotland’s Cabinet Secretary for Environment, Climate Change and Land Reform, officially launched the Shieldhall Tunnel.

A major environmentally friendly project for Scotland

This now-completed project delivers major environmental benefits to Greater Glasgow, including a cleaner River Clyde. By providing additional storage capacity of 90,000 cubic metres, which is equivalent to 36 Olympic-sized swimming pools, the new tunnel will relieve the current sanitation network and reduce flooding risk in the region. At the official launch of the Shieldhall Tunnel, Environment Secretary Roseanna Cunningham emphasised the structure’s strategic importance: “Communities across Glasgow will benefit for years to come from this latest extraordinary feat of engineering, which lies hidden deep beneath the city.” Completion of the Shieldhall Tunnel is a key achievement in the broader programme designed to modernise Glasgow’s current wastewater-management network.

Leveraging leading-edge expertise to ensure successful project delivery

A work team nearly 100-strong was mobilised for a period of two years to achieve this major project. A slurry shield tunnel-boring machine (TBM), named Daisy the Driller by a local schoolboy, was used on the project. This 1,000-tonne, 180-metre-long TBM was launched into a cut-and-cover trench 200 metres long, 6 metres wide large, and 10 metres deep. Construction of the trench required excavating more than 25,000 tonnes of material in a very constricted working area in close proximity to local residents. The TBM was used in a very busy urban setting beneath active railways and former coal quarries that required treatment prior to the TBM’s passage.

In all:

- More than 500,000 tonnes of soil, stone, and clay were excavated, and 90% of this material was recycled

- More than 3,200 concrete rings were installed

- 5 million work hours were required to complete the project